cnc lathe machine process CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries. LONG LASTING AND NEVER RUST – Made of brilliant treated steel, ecological cordial. This will be your LAST litter box and it will turn out to .

0 · cnc turning lathe machine

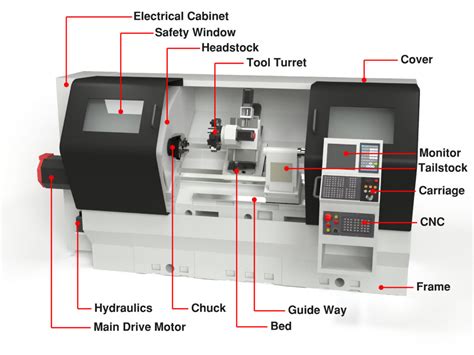

1 · cnc lathe machine working

2 · cnc lathe machine diagram

3 · cnc lathe drawing

4 · cnc lathe diagram

5 · cnc lathe and milling machine

6 · centering operation on lathe machine

7 · 3 axis cnc lathe

Buy 16” XL Stainless Steel Cat Litter Box Enclosure, XXL Stainless Steel Litter Box High Sides with Lid, Extra Large Metal Cat Litter Box, Anti Leakage, Non-Sticky, Easy Cleaning, Includes Scoop at Walmart.com

Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or more axes to shape the material.

buy full metal housing inductive sensors

CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, . Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or . Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or more axes to shape the material.

cnc turning lathe machine

CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries. Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or more axes to shape the material.

Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and rotating a workpiece around a cutting tool. CNC lathe machine operations are many and varied, while results largely depend on the tools used with the machine. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer. What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. The process of cutting any workpiece that rotates on the spindle is known as .

cnc lathe machine working

cnc lathe machine diagram

A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool.

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

CNC lathes are advanced computerised machine tools that have been engineered to enhance precision turning operations. Standing for "Computer Numerical Control," CNC lathes allow for a lathe's movements and operations to be controlled by a computer program.

Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or more axes to shape the material.CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries. Machining Process: The CNC lathe, guided by the G-code, begins the machining process. The workpiece is rotated at high speeds while the cutting tool is moved across two or more axes to shape the material. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and rotating a workpiece around a cutting tool. CNC lathe machine operations are many and varied, while results largely depend on the tools used with the machine.

What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. A CNC lathe(CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by coded instructions fed to a computer.

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though. The process of cutting any workpiece that rotates on the spindle is known as .A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool.

CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

cnc lathe drawing

cnc lathe diagram

Yangbaga Stainless Steel Litter Box for Cat and Rabbit, Odor Control Litter Pan, Non Stick, Easy to Clean, Rust Proof, Large Size with High Sides and Non Slip Rubber Feets

cnc lathe machine process|cnc lathe machine diagram