sheet metal lap joint welding Lap joint. A lap joint is formed when the surfaces of the two pieces overlap one another. The weld is deposited in the joint where the two intersect. A lap joint exhibits good mechanical properties, especially when you weld both . A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

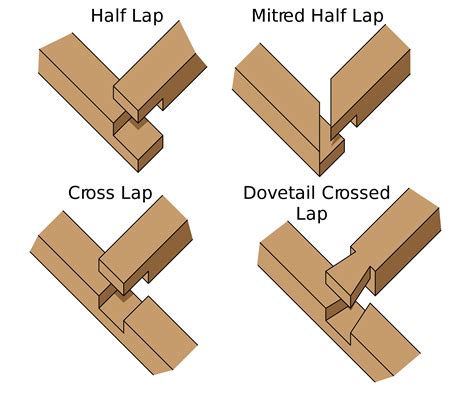

0 · types of lap joint

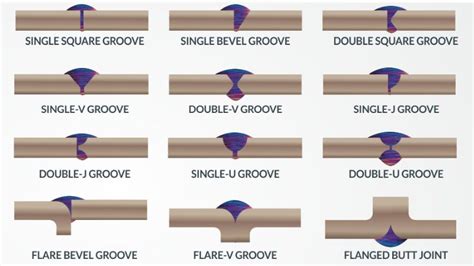

1 · types of butt weld joints

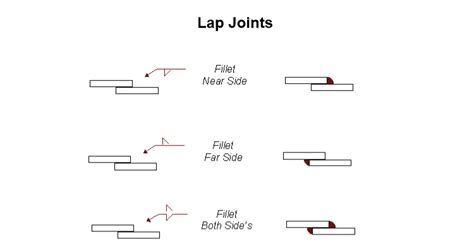

2 · lap joint welding symbol

3 · lap joint welding procedure

4 · lap joint vs butt

5 · lap joint definition welding

6 · lap joint advantages and disadvantages

7 · double full fillet lap joint

This article delves into the fundamental aspects of electrical disconnects, examining the various types available, the critical requirements for emergency disconnects, .

types of lap joint

26 guage stainless steel metal sheet

types of butt weld joints

Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Lap Joints (Plain and Flush) Forming a lap joint involves overlapping two . Frequently used for creating metal storage tanks, where the sealed edges help prevent leaks. These five basic welding joints—Butt, Corner, Lap, T, and Edge—each have their own strengths, limitations, and . Lap joint. A lap joint is formed when the surfaces of the two pieces overlap one another. The weld is deposited in the joint where the two intersect. A lap joint exhibits good mechanical properties, especially when you weld both .

Lap joint welding is a welding technique where two pieces of metal are overlapped and welded together. This technique is essentially a modified version of the butt joint, with the main difference being that the metals are not .Welding joints are critical connections in sheet metal fabrication that determine the strength and durability of a structure. This article will delve into the various types of weld joints, exploring . Lap welds connect two pieces of metal when one partly lays upon the other or they meet at right angles. The weld offers you options for welding one side or both for additional strength. The weld often is used on sheet metal and .

A lap joint is a type of joint where two pieces of sheet metal are overlapped and then welded together. It’s a popular choice for a variety of reasons – it’s relatively easy to execute, it provides a strong and durable . A lap joint in welding refers to a type of joint used to join two metals with different thicknesses. . A lap joint in sheet metal is a type of joint where one piece of metal is placed over another piece, or between two other pieces. This joint design allows for the sheets of metal to be joined together securely.

26 gauge sheet metal duct

1 Common Weld Joints in Custom Sheet Metal Fabrication. 1.1 Open corner weld joint 1.2 Closed corner weld joint 1.3 Spot-Weld Flange Joint; 2 Consult Your Sheet Metal Fabricator about the Optimal Joining Method. 2.1 . The thing with lap joint (IMO as always) is that, it's not a butt joint but more of a T joint style of weld, so, if you have scrap, test it with different settings and see where the metal bends the least and where weld quality is good. So 45ish angle, I'd set the machine to around 16-14 gauge, since its not structural and it's sheet metal. Strategized friction stir welded AA6061-T6/SiC composite lap joint suitable for sheet metal applications. Author links open overlay panel Suresh S a . 6061-T6 sheets of 100 mm × 100 mm × 2 mm and SiC nanoparticle fillers of 50 nm in diameter were used for lap weld joints. Al 6061-T6 alloy has aluminium with Mg of 0.708%, Si of 0.43%, and Fe . The weld often is used on sheet metal and makes the weld even stronger when you lay it on both sides. Lap welds can be difficult for those who do not perform them often. Experience, patience, and preparation make them much easier. . To stick weld a lap joint, first set up your welding machine and supplies. Next, tack weld the two pieces of .

butt welding is the correct way to do it. you will be welding real metal so warping really shouldn't be an issue if you move around. do a couple practice pieces to get the settings right and find a comfort zone. it's only metal and any screw ups can be repaired if you don't warp the shit out of it. just take your time and you'll get the hang of it real quick. good helmut, good .11. At least three operations are to be incorporated in the project.(Welding, Casting, Sheet metal) 12. Moving parts in your project will be given extra credit during evaluation. . the joint region and establish a firm weld. The flame temperature can be controlled by changing the gas composition i.e. ratio of oxygen to acetylene. The color of . The Eastwood Pneumatic Perfect Panel Prep Tool easily provides a perfectly beveled 45° weld-prepped edge in 20 or 18 Gauge sheet metal to achieve solid, full-penetration welds with little distortion. Each pull of the trigger will create an .062″ flange with a 45 degree flange that will give you flush lap joint when laying 20 or 18 gauge over .

What are the Five Types of Welding Joints? The five kinds of weld joints are butt, corner, lap, tee, and edge joints. 1. Butt Joint. A butt joint is a common type of joint used in the fabrication of structures and piping systems, where two pieces of metal are placed together in the same plane, and the side of each metal is joined by welding.

Welding sheet metal parts. Christopher Dawes CEng, in Laser Welding, 1992. Lap seam joint. The lap seam joint is the most common laser welded sheet metal joint because it offers the most versatility from a design standpoint in respect of ease of manufacture under production conditions.

The butt joint includes a groove weld while the lap joints use fillet welds. The differ-ence is, stress flow is more associated with the joint type, . This provision restricts the maximum fillet weld size to the thickness of the base metal for material less than 1/4 in. (6 mm) thick, and for heavier material, to the thickness of .

4. Lap joint welding. Lap welding joints are essentially a modified version of the butt joint. They are formed when two pieces of metal are placed in an overlapping pattern on top of each other. They are most commonly used to joint weld two pieces with differing thicknesses together. Welds can be made on one or both sides. Image credit Science .

Lap Joint Welding . A lap joint consists of two metal pieces overlapping, usually at an angle of 0° to 5°. This design finds widespread use in sheet metal work, automotive manufacturing, and piping because of its simple assembly and strong performance. The most common type of weld is the butt weld, which joins two pieces of metal at their ends. A lap joint weld joins two pieces of metal that overlap each other, while a T-joint weld joins two pieces of metal at right angles to each other. Other types of welds include the corner weld, the edge weld, and the slot weld. For instance, in the production of car bodies or appliance frames, where thin sheet metal is commonly used, lap joints help prevent the material from deforming during the welding process, ensuring a cleaner and more precise weld. Ease of Use for Welders. Lap joint welding is considered relatively easy to perform, even for less experienced welders. Lap Weld Joints: Overlap two pieces of metal and weld along the edges of the overlap: Various industries: . Selecting the appropriate weld joint type for a sheet metal project is essential for achieving the best results in .

Types of Sheet Metal Joints . The different types of Sheet Metal Joints are: 1. Lap Joint: Fig 1: Lap Joint. A lap joint is one of the most common types of sheet metal joints. It involves overlapping two sheets of metal and .

There are five types of welding joints: corner, butt, lap, tee, and edge. Each type has a specific purpose and ensures solid and durable structures. . they create a corner joint. Sheet metal workers, framers, and box constructors commonly use this type of joint to form an external corner. Corner Joint: Pros & Cons. Pros: However, welding a butt weld is much harder and you have to make sure that the cut and fitment is exact and that there are not gaps between these panels. Now on to lap welds. A lap weld is a flanged, dual layered joint where the two pieces of sheet metal overlap and they're usually seam welded and spot welded as well. Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.

In this Video it shows you how to set your MIG machine up for a Lap joint in the Horizontal/Vertical position (PB).Corner Joint Welding. The sheet metal sector loves this type of joint. It is used when welding on the outside of the adjoining metal pieces. If you have placed the pieces correctly (at right angles), the finished item will create an L shape. . Lap Joint Welding. If you need to join two pieces of metal that are different thicknesses, a lap .

Lap joints are rarely used on thick materials, and most of the time also used for sheet metal. While doing lap joint welding, you will face some drawbacks. Those are lamellar tearing or corrosion due to overlapping metals. But, you can easily handle them by applying the correct technique and modifying the variables as required. Following are .

The butt joint includes a groove weld while the lap joints use fillet welds. The differ-ence is, stress flow is more associated with the joint type, . This provision restricts the maximum fillet weld size to the thickness of the base metal for material less than 1/4 in. (6 mm) thick, and for heavier material, to the thickness of .

Although the designation overlap is determined by the overlapping joint, in practice it is common to mention the term lap weld, lap weld or lap weld, which is nothing more than a fillet weld or other type of weld applied to these joints. In general, the term lap welding refers to the configuration of overlapping metal parts that are joined by a .

When welding patch panels should you use a lap weld or a butt weld? Along with examples, and simple explanations, this video will help you make that decisio. Arc and resistance welding (Fig. 1 a and b), brazing (or soldering) (Fig. 1 c) and friction stir welding (Fig. 1 d) are among the most commonly used welding processes to produce lap joints in metal sheets.However, its utilization is limited when the sheets to be joined are made from dissimilar materials and is also costlier than alternative processes if weld inspections are .

A Septic Tank Distribution Box, also known as a D-box, is a junction box positioned between the septic tank and the drain field (or leach field). Its primary function is to evenly distribute the effluent (wastewater) from the septic tank .

sheet metal lap joint welding|types of butt weld joints