electric junction box production line material The new TM series junction boxes come ready for the assembly of fixing plates or DIN rails to mount diverse electrical components. The fixing plates are constructed from durable zinc-plated steel and include screws for secure . 4” square and 411/16”, switch, masonry, utility, outlet, ceiling, fan and gangable boxes. Drawn boxes available with concentric knockouts, combining 1/2” and 3/4” knockout. Complete line of .

0 · polyester junction boxes

1 · junction box specifications

2 · junction box size

3 · junction box diagram

4 · instrument junction box drawing

5 · instrument junction box diagram

6 · instrument junction box cable entry

7 · ex e junction boxes

Nails and screws, where used as a fastening means, shall be attached by using brackets on the outside of the enclosure, or they shall pass through the interior within 6 mm (1/4 in.) of the back or ends of the enclosure.

polyester junction boxes

The materials used in manufacturing electrical junction boxes are not merely building blocks; they are the foundation of reliability and performance. The choice between . The new TM series junction boxes come ready for the assembly of fixing plates or DIN rails to mount diverse electrical components. The fixing plates are constructed from durable zinc-plated steel and include screws for secure .

junction box specifications

We have decades of experience in the production of high-quality junction boxes made of polyester. ROSE was the first manufacturer to establish these enclosures as standard in the .

In general, plastic, metal, or a combination of both materials are used to make these boxes, and they come in many shapes and forms for diverse wiring purposes. In a .

Terminal and junction boxes are used to house electrical components and facilitate wiring. When selecting terminal or junction boxes, correct size and adequate protection are the priorities. .

Aluminum, steel, and stainless steel are the most commonly used metals for making junction boxes, each having unique properties suitable for specific purposes. Aluminum is an excellent conductor of electricity, making it .

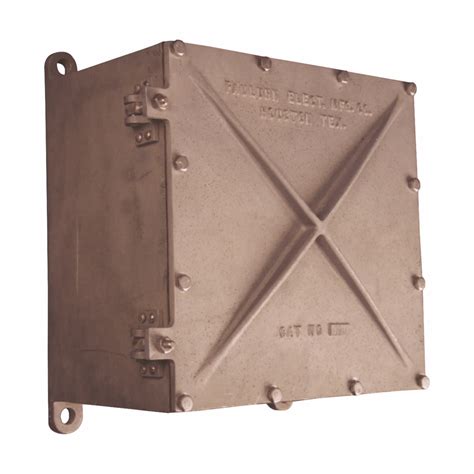

WEMO designs unique and flexible sheet metal production lines for the production of casing and doors for electrical enclosures and distribution cabinets. These fully automatic punching and bending lines deliver a high output against .Junction boxes can be manufactured in a variety of materials including stainless steel, mild steel, glass reinforced polyester, aluminum, polycarbonate and ABS (Acrylonitrile butadiene styrene - a thermoplastic polymer). These are all suitable for a wide range of industrial and OEM applications.

The materials used in manufacturing electrical junction boxes are not merely building blocks; they are the foundation of reliability and performance. The choice between metal and non-metallic materials is driven by the application’s demands, environment, and budget.

junction box size

The new TM series junction boxes come ready for the assembly of fixing plates or DIN rails to mount diverse electrical components. The fixing plates are constructed from durable zinc-plated steel and include screws for secure installation.We have decades of experience in the production of high-quality junction boxes made of polyester. ROSE was the first manufacturer to establish these enclosures as standard in the industry – as terminal boxes, equipment enclosures, enclosures for railway applications and enclosures for E30 fire protection applications. In general, plastic, metal, or a combination of both materials are used to make these boxes, and they come in many shapes and forms for diverse wiring purposes. In a nutshell, junction boxes are important in ensuring power circuits’ safety, order, and efficiency.Terminal and junction boxes are used to house electrical components and facilitate wiring. When selecting terminal or junction boxes, correct size and adequate protection are the priorities. When considering quality of protection, material type and professional rating systems are .

Aluminum, steel, and stainless steel are the most commonly used metals for making junction boxes, each having unique properties suitable for specific purposes. Aluminum is an excellent conductor of electricity, making it ideal for electrical applications.WEMO designs unique and flexible sheet metal production lines for the production of casing and doors for electrical enclosures and distribution cabinets. These fully automatic punching and bending lines deliver a high output against low costs. A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

The company “JV Electric” Ltd. manufactures a wide range of junction boxes for surface mounting and terminals. All the products in our production line are certified according to the “Bulgarian national standart”.

Junction boxes can be manufactured in a variety of materials including stainless steel, mild steel, glass reinforced polyester, aluminum, polycarbonate and ABS (Acrylonitrile butadiene styrene - a thermoplastic polymer). These are all suitable for a wide range of industrial and OEM applications.

The materials used in manufacturing electrical junction boxes are not merely building blocks; they are the foundation of reliability and performance. The choice between metal and non-metallic materials is driven by the application’s demands, environment, and budget. The new TM series junction boxes come ready for the assembly of fixing plates or DIN rails to mount diverse electrical components. The fixing plates are constructed from durable zinc-plated steel and include screws for secure installation.We have decades of experience in the production of high-quality junction boxes made of polyester. ROSE was the first manufacturer to establish these enclosures as standard in the industry – as terminal boxes, equipment enclosures, enclosures for railway applications and enclosures for E30 fire protection applications. In general, plastic, metal, or a combination of both materials are used to make these boxes, and they come in many shapes and forms for diverse wiring purposes. In a nutshell, junction boxes are important in ensuring power circuits’ safety, order, and efficiency.

Terminal and junction boxes are used to house electrical components and facilitate wiring. When selecting terminal or junction boxes, correct size and adequate protection are the priorities. When considering quality of protection, material type and professional rating systems are . Aluminum, steel, and stainless steel are the most commonly used metals for making junction boxes, each having unique properties suitable for specific purposes. Aluminum is an excellent conductor of electricity, making it ideal for electrical applications.

WEMO designs unique and flexible sheet metal production lines for the production of casing and doors for electrical enclosures and distribution cabinets. These fully automatic punching and bending lines deliver a high output against low costs. A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

triangle metal fabrics

junction box diagram

instrument junction box drawing

instrument junction box diagram

The welding rod should be thinner than the base metal, but not thinner than half of the base metal. The thicker the base metal, the larger the welding rod diameter and the amperage. The larger the rod in relation to the .

electric junction box production line material|junction box specifications