solidworks sheet metal assembly You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . Perfect for organizing and displaying your books, office supplies, or other decorative knickknacks, this set comes crafted from solid fir wood and features decorative metal brackets that add a touch of industrial design to your space.

0 · solidworks sheet metal template

1 · solidworks sheet metal examples

2 · solidworks sheet metal download

3 · solidworks sheet metal cut list

4 · solidworks sheet metal basics

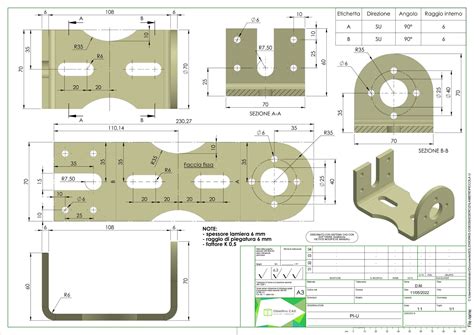

5 · sheet metal solidworks pdf

6 · sheet metal modeling in solidworks

7 · sheet metal in solidworks 2021

Check Trent Sheet Metal Fabrications Ltd in Nottingham, Redwood Court on Cylex and find ☎ 0115 978 0., contact info.

solidworks sheet metal template

You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, .SOLIDWORKS has specific sheet metal features that allow the creation of sheet .To create a sheet metal part, you sketch an open profile and use the base flange .

When creating a tab and slot feature in an assembly component, you can .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of .

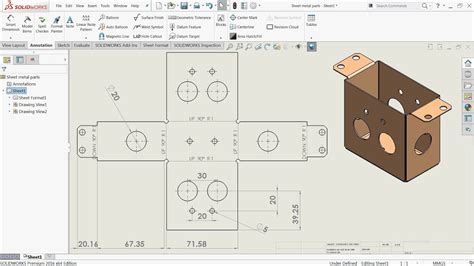

https://www.youtube.com/channel/UCjd_zIvYtQymk0dPx3vTJcA/joinYou Can Support our Channel for more tutorials, We Provide SolidWorks, Autodesk inventor and Fus. This tutorial video we will learn how to sketch sheet metal drawings in Solidworks with the help of sheet metal tools.If you like subscribe our channel for m. By watching this tutorial, you will learn the use of SolidWorks tools like the sketch, pattern, mirror, boss extrude, extrude cut, etc. You also learn the use of sheet metal tools like.

To create a sheet metal part, you sketch an open profile and use the base flange feature to create the thin feature and the bends. You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a .

Learn how to create a piping design in SolidWorks with this step-by-step tutorial! Perfect for beginners, this video will guide you through the entire process, from sketching to .When creating a tab and slot feature in an assembly component, you can propagate the slots to other instances of the same component in the assembly. Stamp Tool. You can use the Stamp .

The Solidworks Sheetmetal Design and Developments software is a powerful tool for designing and developing sheet metal products with ease and precision. Whether you are creating simple brackets or complex enclosures, .Oct 25, 2024 - Explore Mahtabalam Khan's board "SolidWorks Sheet metal" on Pinterest. See more ideas about solidworks, sheet metal, sheet. . SolidWorks Sheet Metal Steel Cabinet (Top-Down Assembly) Metal Tutorial. Cad Cam. .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .When creating a tab and slot feature in an assembly component, you can propagate the slots to other instances of the same component in the assembly. Stamp Tool. You can use the Stamp tool to create sketch-based parametric forming tools to apply to sheet metal parts. With sketch-based forming tools, you can create a sketch with a few parameters .

Solidworks 2022 Sheet Metal Tutorial - Design and Assembly for BeginnersHi and welcome back. Today I am going to show you how to design and assemble a simple.Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .

solidworks sheet metal examples

This tutorial video we will learn how to sketch sheet metal drawings in Solidworks with the help of sheet metal tools.If you like subscribe our channel for m.You can create *.dxf files of sheet metal flat patterns from sheet metal part documents without flattening the model or creating a drawing. This helps to export Dxf files to other applications, such as punch press or laser-cutter programming software. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . between the mitred corners of the top angled flange. Is there a method of creating a similar corner in an assembly of sheet metal components. I have attempted to assemble two folded sheet metal sections overlapping at the corner and then "cut extrude" using .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

To open this dialog box: With a part, assembly, or drawing open, click Tools > Options > Document Properties > Sheet Metal.. To show bend lines in flat patterns, do one of the following: Click View > Hide/Show > Sketches.; In the FeatureManager design tree, expand Flat-Pattern and Flat-Pattern(n).Right-click Bend-Lines and click Show.

To open this dialog box: With a part, assembly, or drawing open, click Tools > Options > Document Properties > Sheet Metal.. To show bend lines in flat patterns, do one of the following: Click View > Hide/Show > Sketches.; In the FeatureManager design tree, expand Flat-Pattern and Flat-Pattern(n).Right-click Bend-Lines and click Show.For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of .The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hello, SW API experts. After a long search on the internet and in this forum, I finally found a macro that does 90% of what I need. . All parts in main assembly and sub-assembly are sheet metal parts. When I run macro, folders are created based on the materials .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

Sheet metal bend lines show up in my assembly. When I open an assembly that contains bent sheet metal components, all the bend lines are showing. I can make the bend lines go away by opening the various sheet metal part models and then closing them. This can take a while if there are a lot of sheet metal parts in an assembly.See how you can take full advantage of sheet metal features on the part, assembly and drawing levels. As a bonus, get an introduction to the costing functionality which will help you assess sheet metal and other production .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .In an assembly, click Tab and Slot (Sheet metal toolbar). In the graphics area, select an edge for the tabs and a corresponding face for the slots. Specify options in the PropertyManager. If SOLIDWORKS detects multiple instances of the component in the assembly, you can specify options under Propagate Slots: Click .This VBA macro allows to export all flat patterns to DXF/DWG from all sheet metal components in the active SOLIDWORKS assembly or an active part document. Macro enables flexibility in specifying the name of the output file allowing to use placeholders (original file name, feature name, custom property, cut-list custom property, etc.) combined .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .- ASSEMBLY exports will export all unsuppressed sheet-metal parts in the active assembly configuration; will not export the same configuration when duplicate instances are found in the assembly. Optional: Add the total configuration instance quantity found in the assembly as a suffix in the exported DXF/DWG filename.Very Large Sheet Metal assembly in SolidWorks. www.egsindia.com 45 Machine made of Sheet metal components. www.egsindia.com 46 Designed and Developed using SolidWorks. www.egsindia.com 47 Ergonomic sheet metal design in SolidWorks. www.egsindia.com 48 Sheet metal design in progress.In an assembly, click Tab and Slot (Sheet metal toolbar). In the graphics area, select an edge for the tabs and a corresponding face for the slots. Specify options in the PropertyManager. If SOLIDWORKS detects multiple instances of the component in the assembly, you can specify options under Propagate Slots: Click .

Help Content Version: SOLIDWORKS Connected Tutorials (3DEXPERIENCE SOLIDWORKS) 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. SOLIDWORKS 2022 Learn by doing: ketching, Part Modeling, Assembly, Drawings, Sheet metal, Surface Design, Mold Tools, Weldments, Model-based Dimensions, Appearances, and SimulationXpress Kishore T 4.5 out of 5 stars 14

Structural hollow sections in grades S235, S355 & S420 amongst others. Discover how Barrett Steel's tubes services can help you. Barrett Steel specialise in hollow section and hold extensive range of stock with a variety of sizes and finishes available.

solidworks sheet metal assembly|sheet metal solidworks pdf