cnc gas cutting machine wiki Gas cutting machines are automated systems that supersede manual cutting torches, offering enhanced productivity, superior cut quality, reduced operator fatigue, and improved cost-effectiveness in metal fabrication . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

0 · what is cnc control

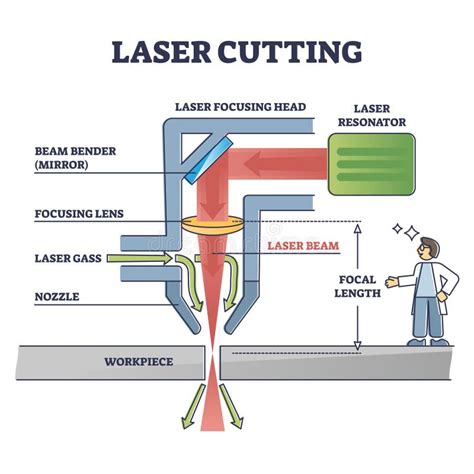

1 · numerical control cnc

2 · laser cutting machine diagram

3 · laser cutting machine

4 · industrial laser cutting machine

5 · history of cnc machines

6 · cnc machine 1940s

7 · 1950s cnc machine

Crafted as a divided lunch box stainless steel, this metal bento box offers three spacious compartments, with a leak-proof design, making it one of the best lunch boxes for kindergarten .

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direc.

metal straddle electrical box

CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting . Gas cutting machines are automated systems that supersede manual cutting torches, offering enhanced productivity, superior cut quality, reduced operator fatigue, and improved cost-effectiveness in metal fabrication .

what is cnc control

When the machine tool moves, the randomly equipped cutting tool cuts the object. This kind of mechatronics cutting machine is called CNC cutting machine. The laser cutting machine has the fastest efficiency and the highest cutting .Linde has engineered our line of industry-leading CNC cutting machines to significantly increase your production capabilities and to reduce your costs of operation in a variety of cutting .

Gas cutting refers to the use of gas flame to preheat the cut metal to the ignition point, so that it burns violently in a pure oxygen stream to form molten slag and release a lot of heat. Under the blowing force of high pressure oxygen, the . Cnc Cutting Definition. CNC flame, plasma, laser and water jet cutting machines, according to the optimized nesting cutting program provided by CNC cutting nesting software .A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, .Oxy-fuel welding torch (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, biodiesel, kerosene, etc) and oxygen to weld or cut metals.

numerical control cnc

laser cutting machine diagram

Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material.

CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting program provided by the CNC cutting nesting software.

Gas cutting machines are automated systems that supersede manual cutting torches, offering enhanced productivity, superior cut quality, reduced operator fatigue, and improved cost-effectiveness in metal fabrication processes.When the machine tool moves, the randomly equipped cutting tool cuts the object. This kind of mechatronics cutting machine is called CNC cutting machine. The laser cutting machine has the fastest efficiency and the highest cutting accuracy, and the cutting thickness is generally small.Linde has engineered our line of industry-leading CNC cutting machines to significantly increase your production capabilities and to reduce your costs of operation in a variety of cutting applications.Gas cutting refers to the use of gas flame to preheat the cut metal to the ignition point, so that it burns violently in a pure oxygen stream to form molten slag and release a lot of heat. Under the blowing force of high pressure oxygen, the oxidized molten slag is blown off.

Cnc Cutting Definition. CNC flame, plasma, laser and water jet cutting machines, according to the optimized nesting cutting program provided by CNC cutting nesting software for full-time, automatic, efficient, high-quality, high-utilization CNC cutting.A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.

Oxy-fuel welding torch (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, biodiesel, kerosene, etc) and oxygen to weld or cut metals.Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material.

CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.What Is CNC cutting? It is an exponentially controlled flame, plasma, laser and water jet cutting machine. It performs full-time, automatic, efficient, high-quality, and high-utilization CNC cutting according to the optimized nesting cutting program provided by the CNC cutting nesting software. Gas cutting machines are automated systems that supersede manual cutting torches, offering enhanced productivity, superior cut quality, reduced operator fatigue, and improved cost-effectiveness in metal fabrication processes.

When the machine tool moves, the randomly equipped cutting tool cuts the object. This kind of mechatronics cutting machine is called CNC cutting machine. The laser cutting machine has the fastest efficiency and the highest cutting accuracy, and the cutting thickness is generally small.

laser cutting machine

Linde has engineered our line of industry-leading CNC cutting machines to significantly increase your production capabilities and to reduce your costs of operation in a variety of cutting applications.Gas cutting refers to the use of gas flame to preheat the cut metal to the ignition point, so that it burns violently in a pure oxygen stream to form molten slag and release a lot of heat. Under the blowing force of high pressure oxygen, the oxidized molten slag is blown off. Cnc Cutting Definition. CNC flame, plasma, laser and water jet cutting machines, according to the optimized nesting cutting program provided by CNC cutting nesting software for full-time, automatic, efficient, high-quality, high-utilization CNC cutting.

industrial laser cutting machine

• UL 50 listed, Type 1 • CSA C22.2 No. 40 certified, Type 1 • Conforms to NEMA standard for Type 1 Type 1, 3, & 3R Enclosures Notes: We can provide special sizes, finishes and other modifications. Consult the factory for your special requirements. Dimensions are in inches. Millimeters shown are for reference only.We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, such as achieving ±0.005 tolerance across multiple bends, which surpasses our recommended .

cnc gas cutting machine wiki|laser cutting machine