cnc machine design features Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best .

Design parts with the sheet metal fabrication process in mind. Reduce cost and get parts on your desk faster! Learn about the following best practices when designing sheet metal parts: Hems & Offsets; Notches & Tabs; Corners & .

0 · technical descriptions of cnc machine

1 · structure of cnc machine tools

2 · specification of cnc machine

3 · main components of cnc machine

4 · explain working of cnc machine

5 · explain Mcu in cnc

6 · cnc machine types and names

7 · cnc controlled machines

Manufacturer Part Number* UPC* * Item/UPC/Part # search method .

technical descriptions of cnc machine

In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few .

Learn all you need to know about CNC machining in 25 minutes or less. .

In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance. Welcome to .Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the .

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, . Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best . CNC machines, or Computer Numerical Control machines, offer a range of advanced features that revolutionize manufacturing processes. These machines excel in precision, automation, and versatility, allowing for complex . Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM .

structure of cnc machine tools

Here are some basic rules to take into consideration when designing CNC machining. Do not use sizes below 20 points when machining text to avoid mistakes within the engraved text. True, CNC machining is versatile, .In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining. In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance. Welcome to the intersection of innovation and precision, where every guideline we share is a step toward manufacturing excellence.

Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide . CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made, but also to . Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to .

CNC machines, or Computer Numerical Control machines, offer a range of advanced features that revolutionize manufacturing processes. These machines excel in precision, automation, and versatility, allowing for complex .

Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining. Here are some basic rules to take into consideration when designing CNC machining. Do not use sizes below 20 points when machining text to avoid mistakes within the engraved text. True, CNC machining is versatile, and not all designs are possible. Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components.

What exactly is computer-numerical-controlled (CNC) machining? It’s a means to make parts by removing material via high-speed, precision robotic machines that use an array of cutting tools to.In this complete guide to designing for CNC machining, we've compiled basic & advanced design practices and tips to help you achieve the best results for your custom parts. There are a few easy steps you can take to optimize your designs for computer numerical control (CNC) machining.

In this guide, we unravel the secrets of CNC machining design. From general best practices to bespoke tips for different CNC operations, we’re diving into how to sculpt your designs for peak CNC performance. Welcome to the intersection of innovation and precision, where every guideline we share is a step toward manufacturing excellence.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .

CNC machining is one of the most widely used prototyping and manufacturing methods today, especially for metal parts. Most of the details, such as tooling, spindle speed, cutter type, and depth of cut, are taken care of at the machine shop, but there are some things you can do while designing your product to not only make sure it can be made, but also to .

specification of cnc machine

Thus, it is essential to adhere to the basic rule of thumb and design guidelines that apply to CNC machining of standard features in CNC machined parts. This guide explores the basics of CNC machining design and best practices for different CNC operations. Read on to . CNC machines, or Computer Numerical Control machines, offer a range of advanced features that revolutionize manufacturing processes. These machines excel in precision, automation, and versatility, allowing for complex . Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining. Here are some basic rules to take into consideration when designing CNC machining. Do not use sizes below 20 points when machining text to avoid mistakes within the engraved text. True, CNC machining is versatile, and not all designs are possible.

Achieving CNC precision requires careful material selection and attention to geometric constraints. This guide explores how these factors impact machining accuracy, cost, and performance, offering practical tips for designing high-quality components.

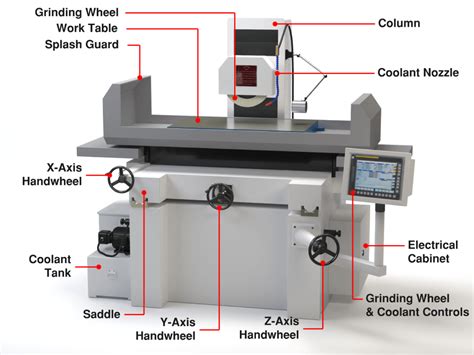

main components of cnc machine

makino cnc machines

Lyon is the number one metal locker supplier in the USA. Let Lyon LLC help you optimize your warehouse, store rooms, and facilities. We offer both Metal Cabinets as well as Modular .

cnc machine design features|main components of cnc machine