embossing operation in sheet metal The metal sheet embossing operation is commonly accomplished with a combination of heat and pressure on the sheet metal, depending on what type of embossing is . See more Troy Products 1024 S. Vail Ave. Montebello, CA 90640 7:30AM to 4:00PM PST. Toll .

0 · sheet metal embossing guidelines

1 · nibbling operation in sheet metal

2 · embossing patterns for metal sheets

3 · embossing disadvantages

4 · embossing dies for metal

5 · embossed copper metal sheets

6 · embossed aluminum sheet metal

7 · copper tooling and embossing techniques

Si la cantidad de corte es superior a mil piezas por día, sugerimos una máquina láser. Tiene ventajas en cuanto a pérdida de corte, costo de operación (0,6 USD/hora) y alta eficiencia (rápida y sin rebabas).

Sheet metal embossing is a metalworking process for producing raised or sunken designs or relief in sheet metal. In contrast to coining (which uses unmatched dies), embossing uses matched male and female dies to achieve the pattern, either by stamping, or by passing a sheet or strip of . See more

1940 ford coupe sheet metal

The metal sheet embossing operation is commonly accomplished with a combination of heat and pressure on the sheet metal, depending on what type of embossing is . See moreThe following materials are suitable for embossing:• Aluminium (all alloys)• Aluminium (T1/T2)• Brass• Cold rolled steel See moreThe metal embossing manufacturing process has these characteristics:• The ability to form ductile metals.• Use . See more

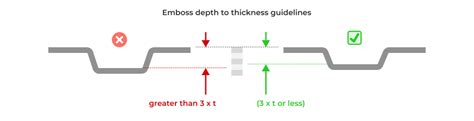

sheet metal embossing guidelines

• Diamond plate• Repoussé and chasing• Paper embossing See more• Metal Embossing on YouTube• The Art and Science of the Sheet Metal Embossing Process (Archived 15 April 2024 at the Wayback Machine)• Embossing metals (Archived 8 December 2021 at the Wayback Machine) See more

What is the embossing process in sheet metal work? The embossing process in sheet metal work involves reshaping a flat metal . Embossing is a critical process in the metal-forming industry that allows for intricate design patterns to be imprinted on metal sheets. Due to its .Metal embossing is a technique used to transform ordinary sheets into three-dimensional crafts. This unique technique requires skill, precision, and a creative eye. Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b.

nibbling operation in sheet metal

embossing patterns for metal sheets

Die creation is an integral part of the sheet metal embossing process. The die is responsible for impressing the desired shape, pattern, or design onto the sheet metal, helping to create embossed or debossed .

Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern.

Metal embossing is a transformative technique that elevates ordinary sheet materials into three-dimensional works of art. This reliable method creates decorative marks and significantly enhances the visual appeal of .

What Are Embossed Metal Sheets? Metal embossing transforms plain metal surfaces into patterned sheets through pressure-based techniques. It creates raised or depressed designs .Sheet metal embossing is a metalworking process for producing raised or sunken designs or relief in sheet metal. In contrast to coining (which uses unmatched dies), embossing uses matched male and female dies [1] to achieve the pattern, either by stamping, or by passing a sheet or strip of metal between patterned rollers. [2] What is the embossing process in sheet metal work? The embossing process in sheet metal work involves reshaping a flat metal surface to create a design that’s either raised (convex) or recessed (concave). Embossing is a critical process in the metal-forming industry that allows for intricate design patterns to be imprinted on metal sheets. Due to its vast range of applications across industries, it plays an integral role in our daily lives, shaping products we often take for granted.

Metal embossing is a technique used to transform ordinary sheets into three-dimensional crafts. This unique technique requires skill, precision, and a creative eye.Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b.

Die creation is an integral part of the sheet metal embossing process. The die is responsible for impressing the desired shape, pattern, or design onto the sheet metal, helping to create embossed or debossed features that enhance the .Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern.

Metal embossing is a transformative technique that elevates ordinary sheet materials into three-dimensional works of art. This reliable method creates decorative marks and significantly enhances the visual appeal of metal products.What Are Embossed Metal Sheets? Metal embossing transforms plain metal surfaces into patterned sheets through pressure-based techniques. It creates raised or depressed designs enhancing both functionality and aesthetics. Core Process: Die imprinting. Roller imprinting In the study presented in this paper, dual-phase DP600 grade steel sheets having a thickness of 1.2 mm were subjected to near-surface unilateral embossing. Here the influence of different.

Sheet metal embossing is a metalworking process for producing raised or sunken designs or relief in sheet metal. In contrast to coining (which uses unmatched dies), embossing uses matched male and female dies [1] to achieve the pattern, either by stamping, or by passing a sheet or strip of metal between patterned rollers. [2]

embossing disadvantages

What is the embossing process in sheet metal work? The embossing process in sheet metal work involves reshaping a flat metal surface to create a design that’s either raised (convex) or recessed (concave). Embossing is a critical process in the metal-forming industry that allows for intricate design patterns to be imprinted on metal sheets. Due to its vast range of applications across industries, it plays an integral role in our daily lives, shaping products we often take for granted.Metal embossing is a technique used to transform ordinary sheets into three-dimensional crafts. This unique technique requires skill, precision, and a creative eye.Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b.

Die creation is an integral part of the sheet metal embossing process. The die is responsible for impressing the desired shape, pattern, or design onto the sheet metal, helping to create embossed or debossed features that enhance the .

Embossing, is a process used to create raised or sunken designs or patterns on the surface of a metal sheet. It involves using specialized tooling and presses to deform the metal, resulting in a three-dimensional pattern. Metal embossing is a transformative technique that elevates ordinary sheet materials into three-dimensional works of art. This reliable method creates decorative marks and significantly enhances the visual appeal of metal products.What Are Embossed Metal Sheets? Metal embossing transforms plain metal surfaces into patterned sheets through pressure-based techniques. It creates raised or depressed designs enhancing both functionality and aesthetics. Core Process: Die imprinting. Roller imprinting

embossing dies for metal

$179.99

embossing operation in sheet metal|embossing disadvantages