spot welding sheet metal repair The key to making good spot welds is getting the welding duration right, so as to not under-weld weak attachments or burn through with excessive weld times. Clean contact and mating surfaces are also critical. With our simple, step-by-step instructions on hand, you’ll have this foundation built and ready to use within minutes. Built with a strong and durable steel frame and a versatile poly jacquard cover that slips right on, the Smart BoxSpring® .

0 · what is resistance spot welding

1 · types of spot welding

2 · spot welding current and voltage

3 · spot welding current

4 · spot welding basics

5 · spot weld aluminum sheet metal

6 · how to spot weld 18galsheetmetal

7 · heat generated in spot welding

The Box of Metal (tm) is an aggressive high-gain pedal with a highly-effective built-in switchable gate which dramatically reduces noise and unwanted feedback. Its gain and tonal characteristics are somewhat similar to high-gain tube amplifiers that have been the staple of hard rock and metal sounds since the 80's.

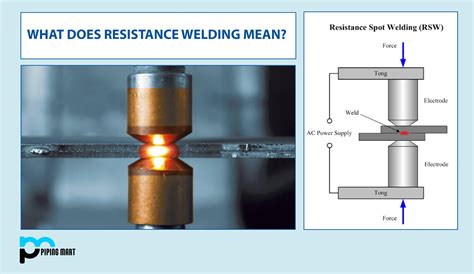

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt weld patch panels on a car.. Spot welding is a crucial technique in manufacturing, but how much do you really know about it? In this blog post, we dive deep into the intricacies of spot welding, exploring its .Spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together by applying pressure and heat from an electric current to the .

crafting technique using thin metal sheets

Most car bodies were spot-welded together at the factory to begin with. Spot welding is a type of electrical resistance welding that joins two or more pieces of steel between two clamping electrodes —it yields a weld at the . The key to making good spot welds is getting the welding duration right, so as to not under-weld weak attachments or burn through with excessive weld times. Clean contact and mating surfaces are also critical.

Spot welding creates a permanent weld by compressing two pieces of sheet metal with copper electrodes, while tack welding is a low-heat, temporary method used to temporarily hold metal pieces in alignment before . Collision repair on modern cars is usually done with panel replacement, but the bodies of older vehicles are commonly welded in the course of repair, restoration or custom modifications. We’ll look at how to do this work . In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I .

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding. . Spot Welding Tongs; Consumables. Find by Product; MIG Gun Consumables; . Powerful Air Spot Weld Drill: you can use it at work to drill spotwelds with ease. Ideal for Automotive Collision Repair, Weld Seams Removal, Sheet Metal Steel Panel Repair. The Air Spot Weld Drill can remove the surface of the solder joints and don't damage the underlying steel plate, adjustable cutting depth.

Portable Metal Butt Welding Gun Steel Sheet Metal Repair Spot Butt Welding Tong. Opens in a new window or tab. Brand New. .90. off 0+ with coupon. If you are unsure of how much metal you have removed, hit the center of the spot weld, and the outline of the spot weld will appear. All of these methods will remove spot welds from sheet metal panels. However, only the spot weld cutter and spot weld drill will allow you to remove the weld without damaging the other panel. In the long run, the . Buy GRAUTOSPOT F98E 110V Spot Welder Dent Puller,3KW Panel Spot Welder Puller,Spot Welding Machine for Car Body Dent Repair: Spot Welding Equipment - Amazon.com FREE DELIVERY possible on eligible purchases . sheet metal repair, and other repair work for damage to the car body. It is also suitable for other metal deformation repairs. VEVOR 110V Spot Welder Dent Puller, 3000W Stud Welder Dent Repair Kit, 7 Models Spot Welding Machine for Car Body Dent Repair. . electrode holder spot welder welding tips electrodes dent pulling puller car spotter gun spot-welding tools sheet metal hook bit Material: copper Contents: 1pc Carbon Rods Holder. Item specifics: .

Powerful Air Spot Weld Drill: you can use it at work to drill spotwelds with ease. Ideal for Automotive Collision Repair, Weld Seams Removal, Sheet Metal Steel Panel Repair. The Air Spot Weld Drill can remove the surface of the solder joints and don't damage the underlying steel plate, adjustable cutting depth. For repair and restoration projects involving metal components, plug welding serves as a reliable method for replacing damaged sections and reinforcing weakened areas, ensuring structural stability and longevity. . In sheet metal fabrication, spot welding is often utilized for creating seams, joints, and connections in various products .

I just did spot welding with a soldering gun on thin aluminum sheet metal using the copper tips provided. The secondary measures 1.0 volts AC so gives ~200 amps and the trigger can hold the current for 5 to 25 seconds of weld time. Beautiful! Cheap!

VEVOR Stud Welder Dent Repair Kit, 110V Spot Welding Machine with Slide Hammer Dent Puller, Professional Dent Removal Kit for Auto Body Dent Repair. 4.1 out of 5 stars. 96. . 86Pcs Profession Car Dent Sheet Metal Repair Tool Kit Dent Puller Welder Kit Car Body Spot Repair Device Stud Welding Hammer Gun Set. 4.1 out of 5 stars. 5.My demonstration using a Lenco Spot Welder. (LencoSpot Welder), (Spot Welding sheet metal), (patch panel spot welder), (auto body spot welder). My demonstrat. Buy GRAUTOSPOT F98ES 110V Spot Welder Dent Puller,3KW Panel Spot Welder Puller,Stud Welder Machine,9 Models Spot Welding Machine for Car Body Dent Repair,Car Repair Shops: Spot Welding Equipment - Amazon.com FREE DELIVERY possible on eligible purchases . sheet metal repair, and other repair work for damage to the car body. It is .

Essential Tips on How to Weld Auto Body Sheet Metal Use the skip welding technique. Using a skip welding technique will help prevent heat build-up and warping. Skip welding consists of laying a series of tack welds about an inch apart and joining them together in a different order instead of one long bead. Noting is worse that doing a repair of any kind then having issues with it that has no good cure. Learning good metal work process takes a teacher that has good metal working skills. Tack welds or in your case Spot Welds are called that for a reason. Then there is Welding up a seam making a repair. Spot Welding. Also known as resistance welding, spot welding involves compressing two pieces of sheet metal and applying pressure and heat from copper electrodes to create a nugget of weld that connects the pieces. .

Spot Weld Cutter, Sheet Metal Hole Cutter, Punch Remover Panel Separator for Power Drill Welding Auto Body Work Tool, 3/8 Inch Drill Bit Tool (9-Pack) . Spot Weld Drill Pneumatic Car Spot Weld Cutter Remover Dent Fix 5/16 1/4" 6.5 8 mm Drill Bits for Automobiles Collision Repair Sheet Metal Steel Panel Repair. Air Powered. 3.5 out of 5 stars . Buy GRAUTOSPOT PRO 110V Spot Welder Dent Puller,1.8KW Panel Spot Welder Puller,5 Models Spot Welding Machine for Car Body Dent Repair: Spot Welding Equipment . sheet metal repair, and other repair work for damage to the car body. It is also suitable for other metal deformation repairs. Welding Processes for Thin or Sheet Metal. Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. MIG Welding (GMAW) MIG welding works fine for thin materials .

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Heating arcs in spot welding. After the correct positioning of workpieces, current starts to flow through the electrodes. While the current flow from one another electrode with high power, the resistance of the workpiece creates heat (H= I 2 RT) and melts the welding area. Electrodes’ melting points should be higher than those of the workpiece.

MIG, TIG, and resistance (spot) welding are the main approaches covered here. Stick Welding. This method was once used to join autobody panel metal, both in production and for repair. This practice involved using small-diameter, coated welding rods that were specifically designed for sheetmetal work.I have some sheet metal parts that I am spot welding together (there are tabs which overlap) and honestly not sure how many spot welds to call out. This is .049" thick material and its a relatively lightweight box that won't see a lot of abuse and doesn't have to hold a ton of weight (<10 lbs). Function: Dented pull rings for spot welding machine body panel pull washer tools. Spot welding straight concave pull ring gasket concave pull welding accessories consumables stud spot welder gasket body shop spot welder. Features: The spot welding gun needs to be connected with the scratch machine (spot welding machine). 100 Pcs dent puller . It is ideal for hobby welders that can complete their sheet metal welding job without requiring a high duty cycle. Best Value for Money. Hobart Handler 140 MIG Welder. Can Weld Up to 1/4" Mild Steel; 20% Duty Cycle at 90 Amps; 115V Supply Only; Includes 10 ft MIG Gun and 10 ft Work Cable with Clamp;

sheet metal repair. Jump to Latest . When you weld it back in use small spot welds spaced out over the entire panel. Start in one spot, tack it, move over 6" and tack again. Keep working around the whole panel until all the tack welds connect to make it solid. If you try to stitch weld it you will warp the panel and cause yourself to do all . – Spot welding is a great option for quick repairs and limited budgets, but when it comes to long-term projects or large structural repairs, you should consider using a more robust method of welding like MIG. Way to repair metal surfaces. The final verdict is that spot welding with MIG is an effective and fast way to repair metal surfaces.

what is resistance spot welding

$37.77

spot welding sheet metal repair|spot weld aluminum sheet metal