what is grain direction in sheet metal LT-Long Transverse: perpendicular to direction of principal metal extension. In products whose grain structure clearly shows directionality (width-to-thickness ratio greater than two) it is that perpendicular direction parallel to the .

To disable the alarm, you will need to find the junction box. Head back down the nearby stairs, and at the second set of stairs, jump onto the crate next to the passage to find the junction box. Return to the doors and enter the new opening.

0 · rolling direction of steel plate

1 · rolling direction of sheet metal

2 · metal grain direction diagram

3 · metal grain direction chart

4 · how to fold metal sheet

5 · how to bend galvanized steel

6 · grain size vs strength

7 · diy sheet metal bending

The cable for each light box goes through a conduit and up to a "deck Box" or junction box per code so water from pool can't run up to the box. In order to change the lights we need to locate the box and pull the wires out, then feed the wires through for the new light. The problem is that one of the boxes seems to be missing.

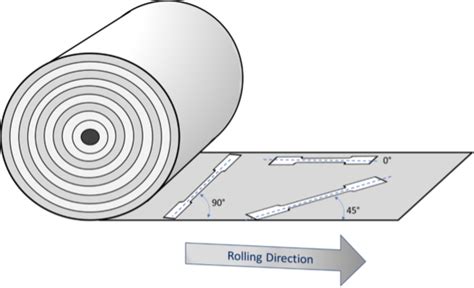

Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. FIGURE 1. Bends made with the grain (that is, the bend line runs parallel to the grain direction) have a greater .

7. Grain Direction. During the process of turning ingots of metal into sheet at the .

Last month we dove into the weeds to understand material grains in sheet .

The direction of the grain is an important factor to consider before any sheet metal fabrication process, but especially before bending, folding, and similar deformation processes. This is because grain direction makes sheet .

7. Grain Direction. During the process of turning ingots of metal into sheet at the mill, the metal is forced between a set of rollers. This process elongates the metal crystals, .

LT-Long Transverse: perpendicular to direction of principal metal extension. In products whose grain structure clearly shows directionality (width-to-thickness ratio greater than two) it is that perpendicular direction parallel to the .In sheet metal, the grains are typically elongated and aligned in a specific direction due to . Last month we dove into the weeds to understand material grains in sheet metal and plate, how they form, and what determines their size and orientation. This month we’ll dive into how exactly those grains affect how a .Like a game of Jenga, aligning grain size and direction helps ensure everything fits together without a hitch. With this article, we'll explore causes of misalignment, troubleshooting tips for .

The answer lies in grain size and direction. By understanding how these two factors affect sheet metal parts, you can ensure that your products are built to last. With the right grain size and direction, you can create a part that is . Grain structure is a crucial factor affecting the performance of sheet metal parts. By controlling grain size and shape, the grain structure of sheet metal parts can be optimized, improving their mechanical properties, surface quality, .3 x thickness of the thickest sheet in the joint What factors determine the number of rivets in a repair? Metal removed or length of repair, thickness and alloy of the material, rivet diameter

I hand understood that forming metal orients its grains, destroying the isotropic nature of 'pure metal' and that the "Long" direction is the length of the sheet/extrusion/etc, and that there were two transverse directions. There is . Hi Friends,In this video you will learn Introduction to sheet metal process | Grain direction | Bend allowance & K-factor | Spring backCheck out other videos.If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . Grain direction is included here for Ss304 parts. For the ortho views, we have all the bend dims. (Special care for non-90 degrees, especially overbends) We include a note .Grain direction is determined by the mill’s rolling process which forms and stretches the microscopic structure and inclusions of the material. The grain direction runs parallel to the rolling direction. For sheet or Panel stock the different directions through the .

While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. . Grain Direction in Metal Bending. When working with plate, pay close attention to whether you are forming with (longitudinal) or across (transverse) the grain direction (see .

catia sheet metal tutorial pdf

Has anybody heard of bending sheet stock (.063 5052-H32 Aluminum)with grain direction on the diagonal? Local sheet metal shop (not an aircraft shop) experienced cracking on folding up a simple bracket. The bracket is like an upside down 6"long x 4"wide x 2"high box but has integral attaching.

The grain structure of sheet metal gets aligned in the rolling direction during the cold rolling operation. When bending soft materials in the rolling direction cracks may appear. Therefore bending in the direction perpendicular to the rolling direction is always preferred. When you make anything out of sheet metal, cabinets, enclosures, chassis, housings. you need to think about the grain structure. Talk to GP PRECISION.https.

rolling direction of steel plate

Grain Flow is a term you will hear throughout the forging industry. But what is it? And why is it so important?All raw materials are processed at a mill or f. This has to do with the sheet grain direction. Where Does Grain Direction Come From? The grain direction is in the rolling direction of the sheet as it was being manufactured. Two rollers compressing the hot metal cause the polycrystalline material to . I am assuming the grain would run the long 8' direction of a sheet 4' x 8' I need to bend the parts across the grain and the material has not shown up yet but I want to nest the parts in the sheet. Sorry for the dumb question I have had these parts cut in the past by someone else with a waterjet and this will be my first try on my router.

Study with Quizlet and memorize flashcards containing terms like Layout & Forming Purpose, Grain, grain determined and more. . the direction of lay of a piece of sheet metal. grain determined. determined by the manufacturing process. Grain rule. all bends must be made so they are not parallel with the grain. Sheet metal with an average yield strength of 41,000 PSI can be sold as A36 steel, even though it is 13 percent harder than 36,000-PSI steel. . Bending with, against, or diagonal to the grain direction will produce different bend angles and inside bend radii, all requiring different bend deductions. This adds yet another variable to your . How do i tell the direction of grain. So i cut 14" and bend slowly, hoping i am going against the grain. Do i drill the holes before ot after the bending. Thanks, Jon . F. . I'm aware that metal has a grain structure and it's of extreme importance as it relates to property phase changes during heat treating but, once a metal is in a useable .Introduction to Mechanical Properties. Tensile property characterization of mild and High Strength Low Alloy steel (HSLA) traditionally was tested only in the rolling direction and included only yield strength, tensile strength, and total .

Run the grain the length of the blade .Bending limits for sheet metal are often different depending on direction. Tool and die work is done annealed then it's hardened .It's important to know the dimensional changes in the three directions. Applying this to metal bending, be it plate bending, press braking or any other type of metal forming, consideration must be given to the grain direction before any process is carried out. As a general rule, the grain line must run perpendicular to the bend to avoid the potential for cracking or fracture. In cases where there are multiple bends . In stainless steel, it can be tough and sometimes impossible to define the grain and grain direction. Materials with a grain direction that affect the bend angle are considered anisotropic. Materials that don’t have this property are considered isotropic. Read more: Grain direction’s effect on sheet metal bending

So if you want to change this you can use the Grain Direction, found by editing the Flat Pattern feature, and selecting an edge or sketch line for the Grain Direction (X). The alternative option is: Select the view to rotate. Select the Rotate View icon found in the Heads-Up Toolbar. Enter the value of the rotation angle. 586631 ‘grain direction and fixed face should be options within doc props>sheet metal’- Provide the user with tools>options>doc props>sheet metal options for fixed face and grain direction. These option will be the default on, but the user has the availability to turn them off via RMB>view properties individually Yes, you can get a Grain direction note added to your drawings in SOLIDWORKS. Your part needs to have a Sheet Metal feature and Flat Pattern feature. Edit the Flat Pattern feature to set the Grain dirction/coil direction first. Then on the drawing, insert a Bend Table and the Grain direction note as well as the Fixed Face note will appear.

For those of you confused about what OP is talking about with this grain direction thing. what he really is talking about is the anisotropy of the steel, or the differences in properties going in different directions. this is a property in every non PM steel, and is a result of the rolling process that the steel is subjected to at the steel mill.Yes, there is a grain. Rolling direction of the sheet metal. Probably long ways left to right if you are standing at it. Reply reply cagerep • Thanks, I thought that would make sense in terms of manufacturing . Include grain direction as needed; 1.0.5 5. Provide powder coat instructions; 2 Sheet Metal Design for Manufacturing. 2.1 FREE eBOOK DOWNLOAD; 3 Sheet Metal Fabrication Drawings FAQ. 3.0.1 Why is it important to list part numbers in addition to part names in sheet metal fabrication drawings?

Study with Quizlet and memorize flashcards containing terms like When practical, bends should be made _____ the grain of the metal, the point of intersection of the mold lines of two sides of a bend is called the _____ point., The distance from the mold point to the bend tangent line is known as the and more.

When bending sheet metal, Inventor states the flange as being bent up when inserting bend notes on drawings but the bend line is actually bent down as would be the case on the press brake as the knife presses into the vee. Does anyone know of the BS or ISO standard drawing principle for this notatio.

rolling direction of sheet metal

metal grain direction diagram

I want to put in a 100amp subpanel in my garage. The run will be underground and 300ft long. I have a Siemens panel with breakers rated at 60/75 deg C. What is the proper wire size I need? I wasHere’s how to install an underground electrical junction box. Step #1: Make sure you pick the right area for installation. Be sure that you are installing the underground box in a .

what is grain direction in sheet metal|rolling direction of steel plate