aluminum fabrication technics Choosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See more Measuring 49.41"L x 24.69"W x 23.43"H, it provides ample storage for patio .

0 · what are fabricated metal products

1 · types of steel fabrication

2 · types of metal processing

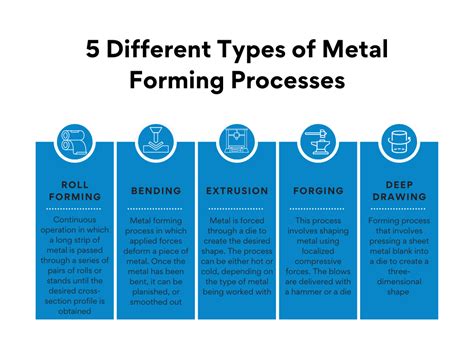

3 · types of metal fabrication processes

4 · manufacturing processes for metals

5 · manufacturing methods for metals

6 · manufacture of fabricated metal products

7 · basic metal fabrication

Junction boxes protect electrical wires from damage, prevent shocks, and stop sparks from igniting flammable material nearby. To install one, you’ll need to strip the ends off all the wires that will be in the box. To complete the electrical circuit, tie together the same-colored wires and hold them in place with wire nuts.

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, . See moreChoosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See more

This guide provides a basic understanding of metal fabrication, the different methods, and considerations for choosing a fabricator. For more . See more Aluminum fabrication are processes or techniques you can use to manipulate aluminum rods, sheets, bars, or tubes to make useful metal parts. Implying, you can cut, bend, .

Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .Aluminum Fabricating Techniques. Shengen is a company that has a constant need to improve its knowledge of aluminum fabrication techniques. We’ll dive into our methods to ensure every piece of aluminum we make is perfect. Aluminum . Four of the most common aluminum forming processes are extrusion, casting, rolling, and forging. Each of these employs a different technique and conveys unique properties to the aluminum. As a result, .

In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all.

Explore emerging trends and cutting-edge technologies in aluminum fabrication, from innovative processes to sustainable practices, shaping the future with us! .

Common aluminium fabrication techniques include cutting, extrusion, drawing, and forming. Cutting involves dividing large sheets of metal into smaller ones, while extrusion uses pressure to shape the metal to fit a die.Metal fabrication is what makes it possible for a wide variety of industries to use aluminum in their products. Whether it’s automobiles, solar panels, architectural structures or spacecraft, some amount of fabrication is necessary to get the . Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Aluminum fabrication are processes or techniques you can use to manipulate aluminum rods, sheets, bars, or tubes to make useful metal parts. Implying, you can cut, bend, assemble and apply suitable surface finishing to get useful aluminum products.

Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves multiple stages, from designing and cutting to forming, machining, and finishing.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies.Aluminum Fabricating Techniques. Shengen is a company that has a constant need to improve its knowledge of aluminum fabrication techniques. We’ll dive into our methods to ensure every piece of aluminum we make is perfect. Aluminum Parts Design for . Four of the most common aluminum forming processes are extrusion, casting, rolling, and forging. Each of these employs a different technique and conveys unique properties to the aluminum. As a result, product designers can use .

In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all. Explore emerging trends and cutting-edge technologies in aluminum fabrication, from innovative processes to sustainable practices, shaping the future with us! [email protected] +91 7666716099Common aluminium fabrication techniques include cutting, extrusion, drawing, and forming. Cutting involves dividing large sheets of metal into smaller ones, while extrusion uses pressure to shape the metal to fit a die.

Metal fabrication is what makes it possible for a wide variety of industries to use aluminum in their products. Whether it’s automobiles, solar panels, architectural structures or spacecraft, some amount of fabrication is necessary to get the aluminum parts to meet their requirements. Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Aluminum fabrication are processes or techniques you can use to manipulate aluminum rods, sheets, bars, or tubes to make useful metal parts. Implying, you can cut, bend, assemble and apply suitable surface finishing to get useful aluminum products.

Aluminum fabrication is the process of transforming raw aluminum into components, parts, or end products through various techniques and methods. This process involves multiple stages, from designing and cutting to forming, machining, and finishing.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies.

what are fabricated metal products

types of steel fabrication

Aluminum Fabricating Techniques. Shengen is a company that has a constant need to improve its knowledge of aluminum fabrication techniques. We’ll dive into our methods to ensure every piece of aluminum we make is perfect. Aluminum Parts Design for .

Four of the most common aluminum forming processes are extrusion, casting, rolling, and forging. Each of these employs a different technique and conveys unique properties to the aluminum. As a result, product designers can use . In the simplest terms, aluminum fabrication is the process of shaping aluminum into a finished design or product. From intricate aerospace parts to everyday household items — aluminum fabrication can do it all.

types of metal processing

Explore emerging trends and cutting-edge technologies in aluminum fabrication, from innovative processes to sustainable practices, shaping the future with us! [email protected] +91 7666716099

types of metal fabrication processes

Common aluminium fabrication techniques include cutting, extrusion, drawing, and forming. Cutting involves dividing large sheets of metal into smaller ones, while extrusion uses pressure to shape the metal to fit a die.

manufacturing processes for metals

$80.00

aluminum fabrication technics|types of metal processing