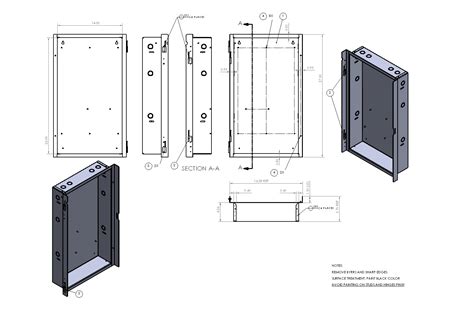

dimension sheet metal drawing Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, . Store and transport ammunition safely and easily with treeline. This steel ammo can has a stackable design for easy storage and a gasket-sealed lid with heavy-duty latch for dry storage. Steel constructed

0 · sheet metal layout drawings

1 · sheet metal drawing symbols

2 · sheet metal dimensioning standards

3 · sheet metal dimensioning guidelines

4 · sheet metal diagram fabrication

5 · sheet metal design basics

6 · sheet metal basic drawing

7 · sheet metal basic design guidelines

Treo by Milton All Fresh Square Glass Lunch Box Set of 3, Clear, 320ml Each, with Lunch Bag, Microwave & Dishwasher Safe, Leak Proof Containers, Borosilicate Glass, Office Tiffin, Grey

sheet metal layout drawings

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this .

sheet metal drawing symbols

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent .

Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, . This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. .

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This . In this article, we’ll discuss how you can make sure you create technically correct and more manufacturable sheet metal drawings. The most important general considerations to make in design are precision in terms of .

sheet metal dimensioning standards

sheet metal dimensioning guidelines

what do the metal stars on people's houses mean

A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of .

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.

Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to . This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. Getty Images. One of the most important aspects of drafting parts is dimensioning.In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

In this article, we’ll discuss how you can make sure you create technically correct and more manufacturable sheet metal drawings. The most important general considerations to make in design are precision in terms of product design and the need to design for manufacturability.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles. Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of .

Sheet metal drawings provide detailed dimensions, tolerances, and material requirements, helping manufacturers accurately understand design intent and produce products that meet specifications. Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to .

This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

Knowing how to dimension a part in a drawing makes metal fabricating that part much easier. Drafting, which you could call the “language of industry,” is not complete without dimensioning, writes Mark Schwendau. Getty Images. One of the most important aspects of drafting parts is dimensioning.In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes

sheet metal diagram fabrication

sheet metal design basics

2PCS Aluminium Soap Travel Box Case, Leak Proof Metal Bar Soap Holder with Lid, Portable Aluminum Tin Jar Containers for Camping Travel Bathroom Candies Jewelry Storage

dimension sheet metal drawing|sheet metal basic drawing