sheet metal development pdf Chapter Objectives. Explain how pattern development is used in the packaging industry. Identify the methods for processing sheet-metal patterns. Describe the general principles of pattern . Siding Mounting Block, Vinyl Siding Light Mounting Block with Built-in Electrical Box, Outdoor Siding Mounting Plate for 1/2 Inch Lap Double - 1 Pack, White

0 · sheet metal layout drawings

1 · sheet metal development calculator

2 · sheet metal design and fabrication

3 · sheet metal bending chart

4 · sheet metal basic design guidelines

5 · free sheet metal layout patterns

6 · free sheet metal layout books

7 · basics in sheet metal design

Vintage Northwestern Mutual Combination Insurance Policy Metal Lock Box! Find great deals on eBay for Vintage Metal Lock Box. Shop with confidence.

Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in .PDF. You can download this book as a PDF to read on a computer (Digital PDF) or print it out (Print PDF). • Mobile. If you want to read this textbook on your phone or tablet, you can use .Chapter Objectives. Explain how pattern development is used in the packaging industry. Identify the methods for processing sheet-metal patterns. Describe the general principles of pattern . Sheet metal drawing and pattern development : Dickason, A. (Alfred) : Free Download, Borrow, and Streaming : Internet Archive. by. Dickason, A. (Alfred) Publication .

The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is . With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques. This book covers material required for a level 1 sheet metal apprentice (Line E).Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .The document discusses different methods for developing sheet metal patterns from objects, including parallel line development, radial line development, and triangular development. It .

features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections.developing sheet metal and other types of protective covers commonly produced for wrap over insulation. The book does not attempt to teach field work-practices or any application methods used in the trade. Learning how to crimp, bead, seam, rivet and apply materials is best accomplished on the job, not from studying a book. However, for theAll sheet metal parts start from flat metal stock and are cut and processed to specifications Sheet metal parts are unique because they use common flat stock materials. The following design guide tips will often describe distances in material thickness, or MT, for relative measurements. sheet-metal-handbook Identifier-ark ark:/13960/t5bd3qk96 Ocr ABBYY FineReader 11.0 (Extended OCR) Page_number_confidence 80.95 Ppi 150 Scanner Internet Archive HTML5 Uploader 1.6.4 . PDF download. .

ASM International staff who worked on this project include Scott Henry, Senior Manager, Content Development and Publishing; Karen Marken, Senior Managing Editor; Steven L. Lampman, Content Developer; Sue Sellers, . 7.2 Lubricants for Sheet Metal Forming...91 7.3 Tribological Tests for Evaluation of Lubricants in Sheet .Addeddate 2017-01-17 19:58:55 Identifier in.ernet.dli.2015.19698 Identifier-ark ark:/13960/t49p88d66 Ocr ABBYY FineReader 11.0used in the sheet metal trade, including layout tools and cutting, bending, and forming machines. Includes safety and maintenance guidelines. Introduction to Sheet Metal Layout and Processes (7.5 Hours) Trainee ISBN 978-0-13-604834-3 Instructor ISBN 978-0-13-604880-0 (Module ID 04103-08) Introduces parallel line development,

The most common method to create simple sheet metal development drawings is by manual drafting and sketching methods. Sheet metal drafting/sketching templates are designed to facilitate layouts of sheet metal air conditioning and heating conduits and are available from manufacturers like Rapidesign®, Pickett®, Staedtler-Mars®, and Timely®.

sheet metal layout drawings

L-shaped metal sheet profile. 25 + 30 + 3,1415/2 x (3 + 0,93) = 61,17 m/m will be the development of the sheet. U shape. Formula: Development = Flat face A + Base + Flat face B + ¶ / 2 x (2 x inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation; U-shaped metal sheet profile The universal sheet metal pattern cutter; a comprehensive treatise on all branches of sheet metal pattern development by Neubecker, William, 1864- [from old catalog] Publication date 1920 Topics Sheet-metal work Publisher New York, N.Y., The Sheet metal publication company . B/W PDF download. download 1 file . CHOCR download. download 1 file . sheet metal drawing and pattern development . Pdf_module_version 0.0.18 Ppi 360 Rcs_key 24143 Republisher_date 20220702201524 Republisher_operator [email protected] Republisher_time 256 Scandate 20220702014303 Scanner .

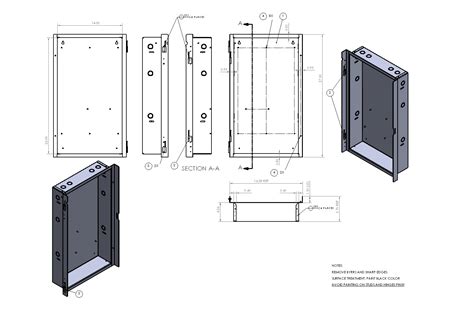

The document discusses surface development, which is the process of unfolding or flattening out the surfaces of a 3D object onto a 2D plane. It defines surface development and explains its importance for sheet metal work and construction. The key methods covered are parallel-line development for prisms and cylinders, radial-line development for pyramids and cones, and .Starting a New Sheet metal File 1. To start a new sheet metal file, click Get Started Launch > New on the ribbon. 2. On the Create New File dialog, click the Sheet Metal.ipt icon, and then click Create. Setting the Parameters of the Sheet Metal part 1. To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the SheetDie design handbook: a practical reference book on process analysis, product design, metal movements, materials, and proved die designs for every class of sheet-metal pressworking by American Society of Tool and Manufacturing EngineersPattern Development: Sheet Metal Level 1. Parallel Line Pattern Development. 15 Equal Diameter 90 Degree Tee We can start to take some short-cuts in our drawing. Instead of drawing a full plan view, we will use profiles. You can always go back to drawing the full plan view!

A metal bending machine for bending 8 feet wide sheet metal into various curves, angles and shapes was designed and constructed. The clamping and the bending beam of the bending machine were made .Surface development is a full size layout of an object drawn on a plane. Some objects are made of flat sheet metal. When the sheet is cut as per this layout, folded and joined together, it takes the shape of an object. Orthographic projections of the object are drawn first and then the development is drawn.BLANK DEVELOPMENT For Formed Sheet Metal Parts There are many systems employed by a variety of industries (aircraft, electronics, architectural, automotive, etc.) to account for "what happens in a sheet metal part when bending it from its flat blank state to Its final bent-upform: "Setbacks ", "Bend Allowances " and "K Factors " are somewhat . Existing conditions at the sheet metal storage area: (A) The storage rack of sheet metals (left), (B) the posture during transfer of the sheet metal from the storage rack (middle), and (C) sharp .

Sheet metal drawing & development by Yarwood, A. (Alfred), 1917-Publication date 1983 Topics . Pdf_module_version 0.0.20 Ppi 360 Rcs_key 24143 Republisher_date 20221029184258 Republisher_operator [email protected] Republisher_time 134 Scandate . The sheet metal cutting machine is the heart of small scale sheet metal industries. Basically the sheet metal cutting machine is hand operated one for medium and small scale industries.The document discusses surface development, which is the process of unfolding or unrolling a 3D object onto a flat plane. It has several key applications in sheet metal work and manufacturing vessels. There are different methods for developing surfaces, including parallel-line development for prisms and cylinders, radial-line development for cones and pyramids, and triangulation .

sheet metal development calculator

The proposed development should be useful in designing and implementing process control in sheet metal forming processes. Schematic representation of a stamping process. Problems in sheet metal .22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern. Bending operation in sheet metal forming has been extensively used in manufacturing technology for mass production especially in automotive industry as one of the tools for shaping into a desired .Cone Layout Development by Marking and Calculation Method with Practical Example. Full Cone is a very common shape in fabrication industry as it is most frequently used shape in fabrication so it is very necessary that every fabrication engineer or professionals in fabrication field must have knowledge of Cone layout Development if you have detailed knowledge of cone .

Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Register Now. Free training, every week, from real experts. 9HUVLRQ 1R 3DJH RI .(7,9 $ &RQWHQWV

Department of Mechanical Engineering, Center for Research and Development College of Engineering, Defence University, Ethiopia E-Mail: [email protected] . circular sheet metal shearing machine, this would replace the punching an d blanking operations and reduce scrap value from the stock material. The research includes concept design .

sheet metal design and fabrication

sheet metal bending chart

Install proper bracing (a simple 2x4 between the rafters should be fine), and attach the electrical box to it. Then mark, and cut a hole for the electrical box in the soffit cover. Finish by putting the soffit cover back in place. Make sure to measure and align the box properly, so the box will be flush with (or just protruding from) the soffit .

sheet metal development pdf|free sheet metal layout books