diy cnc woodworking machine Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.

View and Download Ranger boats Z-Comanche owner's/operator's manual online. Z-Comanche boat pdf manual download. Also for: Z-500, Z-100, Angler, Bay ranger, Reata, Fisherman, Bahia, Ranger trail trailers, Intracoastal.

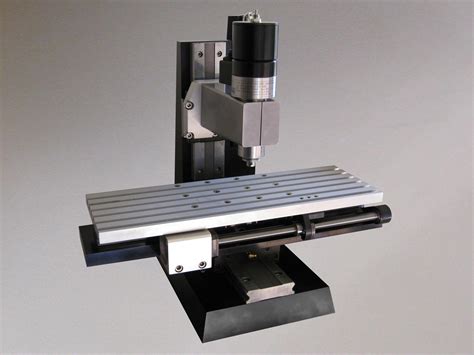

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

Legrand Wiremold Metal Raceway Outlet Box with duplex and faceplate outlet kit for heavy duty applications including brick walls concrete or garages. Easy to install. Paintable and stainable to match any decor.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress . Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step .

Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting .

Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you . Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables .

The best DIY CNC routers give you access to repeatable precision and reliability for your projects - without paying thousands of dollars for professional machines. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts.Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you through the process of building your DIY CNC machine for woodworking, step-by-step.

Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. The best DIY CNC routers give you access to repeatable precision and reliability for your projects - without paying thousands of dollars for professional machines.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Building your own DIY wood CNC machine opens up a world of possibilities for woodworking enthusiasts. With the step-by-step guide provided in this article, you can embark on an exciting journey of creating intricate designs and achieving precise cuts.

Luckily, with a little bit of DIY spirit and some basic knowledge, you can build your own CNC machine tailored to your specific woodworking needs. In this blog post, we will guide you through the process of building your DIY CNC machine for woodworking, step-by-step.Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc.

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

make your own cnc mill

make your own cnc machine

do it yourself cnc machine

The cause was most likely oxidized welds that increased resistance and started the chain reaction. The kettle was most likely still functional right up to the wire disintegrating. The breaker isn't going to trip because it isn't taking more power than expected. But instead of heating the water, it was heating up the wire.

diy cnc woodworking machine|make your own cnc machine