cnc laser cutting machine principle The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both. Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting electrical wiring systems.

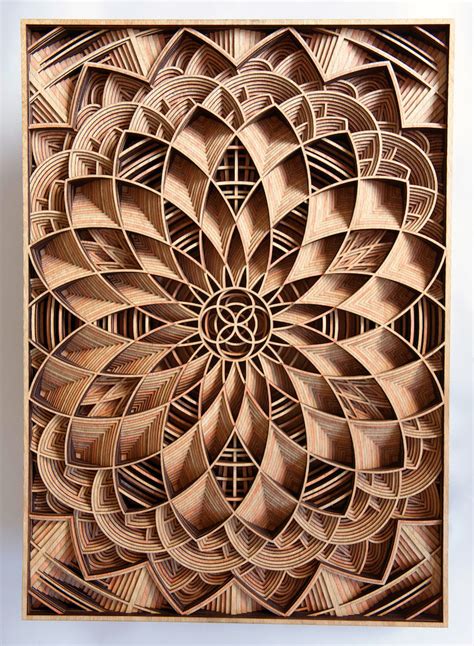

0 · lasercut works

1 · laser cutting requirements

2 · laser cutting guide

3 · laser cutter how it works

4 · laser cutter drawing

5 · how to make laser cutter

6 · cnc laser cutting machine near me

7 · cnc co2 laser cutting machine

$20.00

The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both.The principle of laser cutting. . Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision processing method, laser cutting can cut almost all materials, including two-dimensional or three .Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direc. Laser cutting is a thermal cutting method that uses a focused high-power density laser beam to irradiate the material to be cut, causing the .

What is a CNC Laser Cutter? How Does a CNC Laser Cutter Work? A CNC laser cutter is a machine that is equipped with a computer numerical control (CNC) system, which . A laser cutter works by using a high-powered laser beam to cut or engrave materials with high precision. The process is controlled by computer software, and the laser beam is focused and directed onto the material, which .

Most laser cutting machines are controlled by CNC programs or made into cutting robots. Laser cutting, as a precision machining method, can cut almost all materials, including two-dimensional or three-dimensional cutting of .CNC Controller: The computer numerical control (CNC) system controls the movement of the cutting head and the laser parameters. It follows a programmed path to create the desired cut or engraving on the material. A laser cutting machine is a type of CNC machine. CNC stands for Computer Numerical Controlled. This name comes from the fact that the CNC machine takes commands from drawings that have been digitized and . The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both.

We can define a CNC laser cutter as it is a process of laser cutting service using computerized technology. Just like the other CNC cutting machine. CNC laser engraver also cuts metals, woods, acrylic, paper, and so on. But the only difference is in their cutting tool.

lasercut works

The principle of laser cutting. . Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision processing method, laser cutting can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates. Laser cutting is widely used in electrical manufacturing .Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. Laser cutting is a thermal cutting method that uses a focused high-power density laser beam to irradiate the material to be cut, causing the material to quickly heat up and reach the ignition point, and then melt, ablate, vaporize and evaporate to form holes. What is a CNC Laser Cutter? How Does a CNC Laser Cutter Work? A CNC laser cutter is a machine that is equipped with a computer numerical control (CNC) system, which uses a focused beam of light to cut or engrave materials very accurately. The process starts with a laser source – typically CO2, fiber, or Nd: YAG – that generates the laser beam.

A laser cutter works by using a high-powered laser beam to cut or engrave materials with high precision. The process is controlled by computer software, and the laser beam is focused and directed onto the material, which causes it to heat up and vaporize or melt, creating precise cuts or etchings.

Most laser cutting machines are controlled by CNC programs or made into cutting robots. Laser cutting, as a precision machining method, can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates.

CNC Controller: The computer numerical control (CNC) system controls the movement of the cutting head and the laser parameters. It follows a programmed path to create the desired cut or engraving on the material.

laser cutting requirements

laser cutting guide

laser cutter how it works

A laser cutting machine is a type of CNC machine. CNC stands for Computer Numerical Controlled. This name comes from the fact that the CNC machine takes commands from drawings that have been digitized and transformed into a computer language that describes every angle and curve of that design. The previous article describes the working principle of laser cutting machine and CO2 laser cutting machine and the difference of laser source to not repeat them here. The following will focus on the speed, cutting quality, and maintenance issues of both.

We can define a CNC laser cutter as it is a process of laser cutting service using computerized technology. Just like the other CNC cutting machine. CNC laser engraver also cuts metals, woods, acrylic, paper, and so on. But the only difference is in their cutting tool.

The principle of laser cutting. . Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision processing method, laser cutting can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates. Laser cutting is widely used in electrical manufacturing .

Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. Laser cutting is a thermal cutting method that uses a focused high-power density laser beam to irradiate the material to be cut, causing the material to quickly heat up and reach the ignition point, and then melt, ablate, vaporize and evaporate to form holes. What is a CNC Laser Cutter? How Does a CNC Laser Cutter Work? A CNC laser cutter is a machine that is equipped with a computer numerical control (CNC) system, which uses a focused beam of light to cut or engrave materials very accurately. The process starts with a laser source – typically CO2, fiber, or Nd: YAG – that generates the laser beam.

A laser cutter works by using a high-powered laser beam to cut or engrave materials with high precision. The process is controlled by computer software, and the laser beam is focused and directed onto the material, which causes it to heat up and vaporize or melt, creating precise cuts or etchings. Most laser cutting machines are controlled by CNC programs or made into cutting robots. Laser cutting, as a precision machining method, can cut almost all materials, including two-dimensional or three-dimensional cutting of thin metal plates. CNC Controller: The computer numerical control (CNC) system controls the movement of the cutting head and the laser parameters. It follows a programmed path to create the desired cut or engraving on the material.

alpha steel cabinets philippines

aluminium cnc turning parts

Get information, directions, products, services, phone numbers, and reviews on United Sheet Metal in Capitol Heights, undefined Discover more General Contractors-Single-Family Houses .

cnc laser cutting machine principle|laser cutting requirements