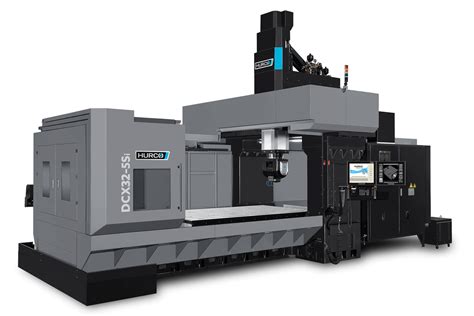

cnc machine parts to move in z direction One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC . We have a wide selection of quality used Hurco machines including vertical machining centers, horizontal machining centers and lathes. Browse our inventory of machines or contact us if you need something that you don't see.

0 · z axis in cnc machine

1 · z axis direction cnc

2 · positive z axis direction cnc

3 · lathe z axis

4 · how to use z axis

5 · cnc z axis function

6 · cnc z axis diagram

7 · cnc z axis chart

$194K+

One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC . For a beginner in Cnc it often makes sense to establish your Z zero position on the Top of the Part, now any positive Number means your Tool is above the Part and a negative . The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.

bathroom vanity light no junction box

Once the computer program directs the CNC machine to use the work coordinate system, the Z axis will refer to the part coordinates. The Z axis has only two movements: up and down. In a . Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. .The Z-axis movements open up a world of possibilities in CNC machining, enabling the creation of complex geometries, multi-level parts, and intricate designs. We will explore various machining .A simple way to visualize this is to associate the Z-axis with elevation or 'height' in the three-dimensional space of a CNC machine. In terms of direction,positive values on the Z-axis .

Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three .

The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed is horizontally moved along the x- and y-axes, while the cutting tool moves vertically along . The positive Z direction is generally upward, away from the workpiece, while negative Z moves downward, towards or into the material being machined. Understanding the .One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process.

For a beginner in Cnc it often makes sense to establish your Z zero position on the Top of the Part, now any positive Number means your Tool is above the Part and a negative Number will be below the Top of the Part. The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.Once the computer program directs the CNC machine to use the work coordinate system, the Z axis will refer to the part coordinates. The Z axis has only two movements: up and down. In a work coordinate system, Z1.0 will position the Z one inch above the part. This is a safe space to send the Z axis or rather, the tool, before cutting begins. Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line.

The Z-axis movements open up a world of possibilities in CNC machining, enabling the creation of complex geometries, multi-level parts, and intricate designs. We will explore various machining techniques that leverage the Z-axis, such as pocketing, profiling, drilling, and thread milling.

A simple way to visualize this is to associate the Z-axis with elevation or 'height' in the three-dimensional space of a CNC machine. In terms of direction,positive values on the Z-axis typically denote upward motion,while negative values indicate motion downwards. Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space.The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed is horizontally moved along the x- and y-axes, while the cutting tool moves vertically along the z-axis.

The positive Z direction is generally upward, away from the workpiece, while negative Z moves downward, towards or into the material being machined. Understanding the Z axis orientation is essential for proper tool path programming, setting tool offsets, and ensuring accurate machining results in CNC operations.

One crucial element of CNC machines is the Z-axis, which plays a pivotal role in determining the vertical direction of the tool. In this blog post, we will explore the Z-axis direction in CNC machines, its significance, and how it affects the manufacturing process. For a beginner in Cnc it often makes sense to establish your Z zero position on the Top of the Part, now any positive Number means your Tool is above the Part and a negative Number will be below the Top of the Part.

The movement direction of the Z-axis is particularly significant in CNC machining. Positive Z-axis movement typically raises the cutting tool, while negative Z-axis movement lowers it.Once the computer program directs the CNC machine to use the work coordinate system, the Z axis will refer to the part coordinates. The Z axis has only two movements: up and down. In a work coordinate system, Z1.0 will position the Z one inch above the part. This is a safe space to send the Z axis or rather, the tool, before cutting begins. Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line.The Z-axis movements open up a world of possibilities in CNC machining, enabling the creation of complex geometries, multi-level parts, and intricate designs. We will explore various machining techniques that leverage the Z-axis, such as pocketing, profiling, drilling, and thread milling.

A simple way to visualize this is to associate the Z-axis with elevation or 'height' in the three-dimensional space of a CNC machine. In terms of direction,positive values on the Z-axis typically denote upward motion,while negative values indicate motion downwards. Almost every CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. The coordinate system allows the machine to identify locations, move in specific directions and establish positions in a three-dimensional space.The drive system consists of motors responsible for moving the tool along the various axes of the CNC machine. In a standard CNC mill, the bed is horizontally moved along the x- and y-axes, while the cutting tool moves vertically along the z-axis.

battery junction box for 2019 expedition

z axis in cnc machine

bathroom light electrical box

z axis direction cnc

positive z axis direction cnc

$62.99

cnc machine parts to move in z direction|cnc z axis function