cnc machine presentation Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a .

A non-dividend distribution, you see, is a return of some portion of your original investment; and as such you would need only to reduce the cost basis of your stock, bond, mutual fund, other security, etc.

0 · cnc machine tools ppt

1 · cnc machine ppt template

2 · cnc machine ppt download

3 · cnc machine maintenance ppt

4 · cnc lathe machine working ppt

5 · cnc lathe machine ppt download

6 · cnc drilling machine pdf

7 · basics of cnc machine ppt

The switchgear arrangement on each distribution side is housed in metal-enclosed structures called as LT (low tension) panels. These LT panels are responsible for distributing the power to various sub LT panels by receiving it from the transformer.

CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine .This presentation summarizes the key characteristics of CNC machines. It .Different types of CNC machines such as mills, lathes, and EDM machines are .Computer Numerical Control (CNC) Machining is the process through which .

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of . Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a .Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining .CNC machines have been widely adopted across industries like automotive, aerospace, machinery, and more to enable higher production rates and reduce costs through automated and repeatable machining.

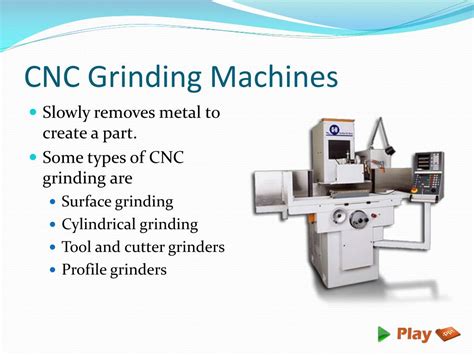

Numerical Control • NC can be defined as a form of programmable automation in which the process is controlled by numbers, letters and symbols. • It means that it is a technique for controlling the machine tool by using coded .CNC (Computer Numerical Control) machines revolutionized the manufacturing industry by enabling precision machining and automation. In this blog post, we will discuss the . Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – .

•The most basic function of any CNC machine is automatic, precise, and consistent motion control. •Rather than applying completely mechanical devices to cause motion as is required . The CNC Machining is an Computer Numerical Control (CNC) machines are automated milling devices that make industrial components without direct human assistance. They use coded instructions that are sent to an . CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine tool, driving system, feedback devices, and display unit.

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today. Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a cylindrical part.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher EducationCNC machines have been widely adopted across industries like automotive, aerospace, machinery, and more to enable higher production rates and reduce costs through automated and repeatable machining.

cnc machine tools ppt

Numerical Control • NC can be defined as a form of programmable automation in which the process is controlled by numbers, letters and symbols. • It means that it is a technique for controlling the machine tool by using coded instructions in the .CNC (Computer Numerical Control) machines revolutionized the manufacturing industry by enabling precision machining and automation. In this blog post, we will discuss the fundamentals of CNC machines and their applications. We have also included PPT presentations that cover topics such as CNC programming, CNC machining, and CNC maintenance. Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – all used for .•The most basic function of any CNC machine is automatic, precise, and consistent motion control. •Rather than applying completely mechanical devices to cause motion as is required on most conventional machine tools, CNC machines allow motion control in a revolutionary manner. •All forms of CNC equipment have two or more directions of

The CNC Machining is an Computer Numerical Control (CNC) machines are automated milling devices that make industrial components without direct human assistance. They use coded instructions that are sent to an internal computer, which allows factories to fabricate parts accurately and quickly.

CNC machining uses computer-controlled machine tools to precisely cut metal or other materials. Key components of a CNC system include the machine control unit, machine tool, driving system, feedback devices, and display unit.

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today. Different types of CNC machines such as mills, lathes, and EDM machines are covered. The presentation also discusses CNC programming basics including codes, tool paths, and an example programming for a cylindrical part.

Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher EducationCNC machines have been widely adopted across industries like automotive, aerospace, machinery, and more to enable higher production rates and reduce costs through automated and repeatable machining.

Numerical Control • NC can be defined as a form of programmable automation in which the process is controlled by numbers, letters and symbols. • It means that it is a technique for controlling the machine tool by using coded instructions in the .

CNC (Computer Numerical Control) machines revolutionized the manufacturing industry by enabling precision machining and automation. In this blog post, we will discuss the fundamentals of CNC machines and their applications. We have also included PPT presentations that cover topics such as CNC programming, CNC machining, and CNC maintenance.

Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – all used for .•The most basic function of any CNC machine is automatic, precise, and consistent motion control. •Rather than applying completely mechanical devices to cause motion as is required on most conventional machine tools, CNC machines allow motion control in a revolutionary manner. •All forms of CNC equipment have two or more directions of

metallic rose gold faux leather fabric

cnc machine ppt template

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

cnc machine presentation|basics of cnc machine ppt