cnc machine applications pdf The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three linear axes, but between operations, the machining table and tool head can swivel in two directions. Logan Millwork is now offering complete CNC Wood Machining. Our leading-edge compact nesting machine allows for extreme precision and repeatability, faster production, lower costs, and the creation of less material waste all without sacrificing detail or quality.

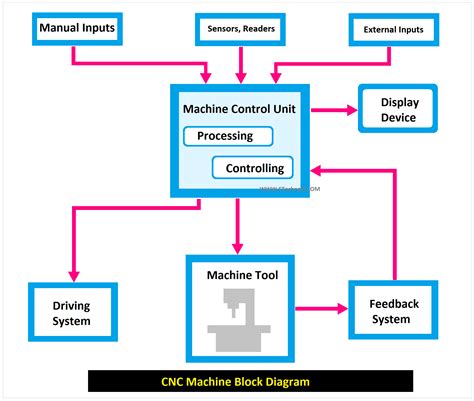

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

For those who prefer wood slats, this box spring combines the strength of steel in the base with the slight give of wood in the slats, which some sleepers say offers a more .

The multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three .Modern CNC Machine Characteristics ØMassive, usually four times heavier than an equivalent conventional (manual) machine. ØLarge motors with high speed capabilities to take advantage .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive RapidThe multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three linear axes, but between operations, the machining table and tool head can swivel in two directions.

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.Modern CNC Machine Characteristics ØMassive, usually four times heavier than an equivalent conventional (manual) machine. ØLarge motors with high speed capabilities to take advantage of modern cutting tools. Horsepower and spindle speeds are generally four to ten times faster than conventional machines.

11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)The variety of cutting tools available for modern CNC turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to common turning processes.automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate measuring machine, electronic assembly, tape lay. g (2 to 5 -axis machining), (6) reduced human error. The drawbacks include high cost, mainten. three basic comp.Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive RapidThe multi-axis CNC machining family includes three processes: Indexed 5-axis CNC milling: During indexed 5-axis milling operations, not only can the cutting tools move along the three linear axes, but between operations, the machining table and tool head can swivel in two directions.

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

schematic diagram of cnc machine

products made by milling machine

Modern CNC Machine Characteristics ØMassive, usually four times heavier than an equivalent conventional (manual) machine. ØLarge motors with high speed capabilities to take advantage of modern cutting tools. Horsepower and spindle speeds are generally four to ten times faster than conventional machines.11. Application of CNC Machine Tools The machines controlled by CNC can be classified into the following categories: CNC mills and machining centers, CNC lathes and turning centers CNC electrical discharge machining (EDM) CNC grinding machines CNC cutting machines (laser, plasma, electron, or flame)

The variety of cutting tools available for modern CNC turning centers makes it imperative for machine operators to be familiar with different tool geometries and how they are applied to common turning processes.

automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate measuring machine, electronic assembly, tape lay. g (2 to 5 -axis machining), (6) reduced human error. The drawbacks include high cost, mainten. three basic comp.Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. State the objectives, advantages, and special requirements concerning CNC use. Identify the different media used to input and store CNC programs. Describe the two different punched-tape formats used with CNC machines.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

industries that use cnc machines

dumbo metal lunch box

Hickory Hardware Woodgrain 3 Inch Center to Center Wood Cabinet Handle / Drawer Pull with Metal End Mounts

cnc machine applications pdf|different type of cnc machines