4 axis cnc parts 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials . Harder than our other 304 stainless steel, these thin sheets offer better wear resistance for use as a wrap, liner, or cover.

0 · cnc 4th axis for sale

1 · 4th axis for cnc mill

2 · 4 axis hobby cnc

3 · 4 axis desktop cnc mill

4 · 4 axis desktop cnc

5 · 4 axis cnc mill cost

6 · 4 axis cnc machine price

7 · 4 axis cnc for sale

El uso de tornos CNC mejora la competitividad de las empresas al permitirles producir piezas de alta calidad de manera eficiente y a menor costo. Esto es crucial en un mercado global donde .

4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials .4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.

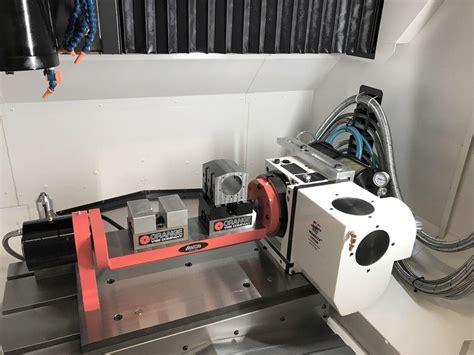

spot weld aluminum sheet metal

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers. 4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the manufacturing process.The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece.

All CNC machines are built around these basic axes for every hole, cut and feature machined. Today, more advanced CNC machines add a fourth or fifth axis to expand even more machining without resetting the workpiece. In fact, the first step in .

The basic principles of 4-axis CNC machining involve using CAD (Computer-Aided Design) software to create a digital model of the desired part or component. This model is then converted into machine code, instructing the CNC machine on how to . This blog-post covers what 4 axis CNC machining is, its key benefits, differences between 3, 4 and 5 axis CNC machining, and ideal uses for 4 axis machining. What is 4 Axis CNC Machining? axis CNC machining utilizes Computer Numerical Control . 4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .

4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. 4-axis CNC machining is a versatile process for machining different components ranging from small electronic parts to large aerospace machined parts. They are also suitable for handling various CNC machining materials and part sizes.4-axis CNC machining is a type of advanced machining that uses CNC machines with an extra rotating axis. This rotation lets you work on four sides of a part while it remains clamped in one position, requiring only a single setup. In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.

4-axis CNC machining works by adding a rotary axis, known as the A-axis, to the traditional X, Y, and Z axis. The A-axis allows the machine to rotate the part being worked on, which adds greater precision and flexibility to the manufacturing process.

The key components of a 4-axis CNC machine include the machine bed, spindle, chuck or collet, and the rotary axis. The spindle holds the cutting tool and moves along the X, Y, and Z axes, while the rotary axis rotates the workpiece. All CNC machines are built around these basic axes for every hole, cut and feature machined. Today, more advanced CNC machines add a fourth or fifth axis to expand even more machining without resetting the workpiece. In fact, the first step in .The basic principles of 4-axis CNC machining involve using CAD (Computer-Aided Design) software to create a digital model of the desired part or component. This model is then converted into machine code, instructing the CNC machine on how to .

This blog-post covers what 4 axis CNC machining is, its key benefits, differences between 3, 4 and 5 axis CNC machining, and ideal uses for 4 axis machining. What is 4 Axis CNC Machining? axis CNC machining utilizes Computer Numerical Control .

4 Axis CNC machines find widespread use across various industries, underscoring their versatile applications: Aerospace: The production of parts such as turbines, propellers, and antennas that require complex geometries and high precision is .

spokane metals fabrication

cnc 4th axis for sale

square electrical junction box

4th axis for cnc mill

4 axis hobby cnc

Maslow4 is a large format CNC router. That means its a robot which lets you cut full sheets of plywood without having to break them down into smaller pieces. Maslow4 is affordable, open source, and actively developed by an incredible community.

4 axis cnc parts|cnc 4th axis for sale