cnc machine shavings flying Download Process of the cnc machine. Metal shavings flying, part milling Stock Video and explore similar videos at Adobe Stock. Five types of pipe—PEX, PVC, ABS, copper, and galvanized—are commonly found in houses these days. In this article, we will cover the types of plumbing used in homes and discuss the pros and cons for each.

0 · Thoughts on my first CNC desktop mill : r/hobbycnc

1 · Swarf

2 · Process of the cnc machine. Metal shavings flying, part milling

3 · Metal swarf

4 · ELI5: When you cut metal why do you get chips and

5 · Coolants and Swarf

6 · Cnc machine is creating a metal detail, with metal shavings flying

7 · CNC Machining

8 · 1910.212

Types of tools: There are different types of tools for different CNC machines and purposes. Some of the most common and useful tools are bits, end mills, face mills, ball nose end mills, V-bits, chamfer bits, drill bits, taps, grinding wheels, etc.

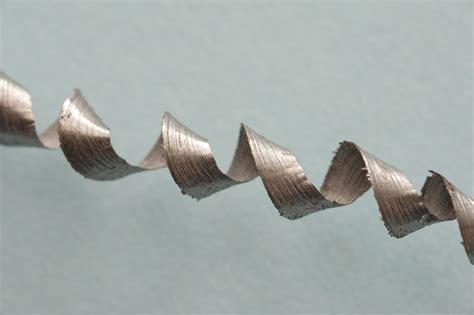

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-removing) manufacturing processes. Swarf can be small particles (such as the gritty swarf from grinding metal or the sawdust from sawing or sanding wo.Metal swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal that are the debris or waste resulting from machining or similar subtractive (material-removing) manufacturing processes. Metal swarf can be small particles (such as the gritty swarf from grinding metal) or long, stringy tendrils (such as the springy chips from turning tough

home depot concrete pier block with metal bracket

Download Process of the cnc machine. Metal shavings flying, part milling Stock Video and explore similar videos at Adobe Stock. When I go at 4000 RPM, there are no sparks or embers. At 6000 RPM, orange glowing steel is flying everywhere. This is not the result I was expecting, I usually do aluminum .Swarf (or filings, shavings, metal chips or turnings) are waste materials removed by grinding, drilling, turning, milling or cutting tools in the machining of metals, wood, stone and other elements. The form of the machine shavings will .

Assuming CNC is what you meant, milling will cut the metal, of course it shaves it off. But dust do present in all cases, just that you could not see them. Sometimes if water or oil is injected, that makes it even harder to spot dust.

home depot metal junction boxes

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, .How will you deal with shavings flying around on that tidy desk? Looks cool! Looks may more solid than the Milo 1.5. Now all you need to add is a 20 position ATC l, tool setter etc. 😁. Why .Download Cnc machine is creating a metal detail, with metal shavings flying off the piece being worked on Stock Photo and explore similar images at Adobe Stock. Depending on your CNC Machine, methods for doing this will range from manual brushing and air nozzle work, to coolant washdown, to automated mechanisms like chip augers and conveyors. Chip Augers are powered auger screws that move swarf out of .

home depot metal junction boxes

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-removing) manufacturing processes.

Metal swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal that are the debris or waste resulting from machining or similar subtractive (material-removing) manufacturing processes.Download Process of the cnc machine. Metal shavings flying, part milling Stock Video and explore similar videos at Adobe Stock. When I go at 4000 RPM, there are no sparks or embers. At 6000 RPM, orange glowing steel is flying everywhere. This is not the result I was expecting, I usually do aluminum but I thought it was acceptable to run AlTiN coated carbide on .Swarf (or filings, shavings, metal chips or turnings) are waste materials removed by grinding, drilling, turning, milling or cutting tools in the machining of metals, wood, stone and other elements. The form of the machine shavings will depend completely on the type of .

Always had parts with shaving wrapped around thread causing an alarm when feeding into sub or have to remove before shipping parts. This time after threading went back in with

The issue we are having is small shavings. We do a lot of brass cutting with .125 EM which produces very small shavings. We use the air blast instead of liquid coolant for many reasons but its also a lot less messy.

Assuming CNC is what you meant, milling will cut the metal, of course it shaves it off. But dust do present in all cases, just that you could not see them. Sometimes if water or oil is injected, that makes it even harder to spot dust.One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks.

Thoughts on my first CNC desktop mill : r/hobbycnc

Swarf

Depending on your CNC Machine, methods for doing this will range from manual brushing and air nozzle work, to coolant washdown, to automated mechanisms like chip augers and conveyors. Chip Augers are powered auger screws that move swarf out of .Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-removing) manufacturing processes.

Metal swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal that are the debris or waste resulting from machining or similar subtractive (material-removing) manufacturing processes.

Process of the cnc machine. Metal shavings flying, part milling

Download Process of the cnc machine. Metal shavings flying, part milling Stock Video and explore similar videos at Adobe Stock. When I go at 4000 RPM, there are no sparks or embers. At 6000 RPM, orange glowing steel is flying everywhere. This is not the result I was expecting, I usually do aluminum but I thought it was acceptable to run AlTiN coated carbide on .Swarf (or filings, shavings, metal chips or turnings) are waste materials removed by grinding, drilling, turning, milling or cutting tools in the machining of metals, wood, stone and other elements. The form of the machine shavings will depend completely on the type of .

Always had parts with shaving wrapped around thread causing an alarm when feeding into sub or have to remove before shipping parts. This time after threading went back in with

The issue we are having is small shavings. We do a lot of brass cutting with .125 EM which produces very small shavings. We use the air blast instead of liquid coolant for many reasons but its also a lot less messy. Assuming CNC is what you meant, milling will cut the metal, of course it shaves it off. But dust do present in all cases, just that you could not see them. Sometimes if water or oil is injected, that makes it even harder to spot dust.

home depot electrical enclosure box

home depot metal box extender

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

cnc machine shavings flying|Process of the cnc machine. Metal shavings flying, part milling