8mm drill bit for cnc machine feed rate We offer both that free online drill feeds and speeds calculator using simple shop formulas, and also a free (for a limited time) full-featured calculator that is the industry leading speeds and feeds calculator. Electrical junction boxes are essential for different applications: Adding an electrical outlet in a new room or area of a building. Extending wiring to power a ceiling fan or additional electrical appliances in a kitchen. Installing a new wall switch to control lighting in a different part of a room.

0 · feed rate calculator cnc

1 · drill speeds and feeds calculator

2 · drill speeds and feeds

3 · drill feeds chart

4 · drill feeding speed chart

5 · drill feed rate calculator

6 · cnc speeds and feeds

7 · cnc drill feed calculator

Metal fabrication is a manufacturing process that shapes raw metal into structures via cutting, bending, and assembling techniques. Metal fabricators are referred to as fab shops. Fabricators and machine shops are similar, except that .

We offer both that free online drill feeds and speeds calculator using simple shop formulas, and also a free (for a limited time) full-featured calculator that is the industry leading speeds and feeds calculator.That drill depth is measured from R. So, with an R of 0.2″, and a depth (Z) of . Please follow these steps to see if it works for you, Step 1 - Type in Feed rate in in/min (mm/min will be calculated from it) Step 2 - Pick the suggested chip load based on your material type and tool diameter. Feed Rate Calculator. When milling or drilling, or creating a tool path for a CNC .

Most machine controllers allow you to adjust the feed rate while a program is running and by listening to the sound the cutter makes this can be a good way of optimizing the parameters. .The Best Online Speeds and feeds calculator. For Milling, Turning, Drilling, Grooving, and Parting off. Results: Cutting conditions and Grades

Determine the spindle speed (RPM) and feed rate (IPM) for a drilling operation, as well as the cut time for a given cut length. Drilling operations are those in which a cutting tool with sharp .A good starting point for drilling steel with a HSS drill bit would be 75 SFM with a feedrate of .001/tooth or .002” per rev. For aluminum I would use 130 SFM and keep the feedrate at .002” .

metal brackets for kitchen shelves

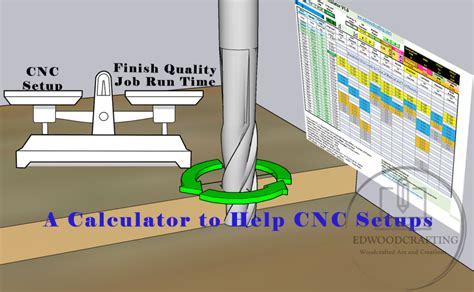

Speeds and Feeds Calculator This software can be used to determine the cutting parameters for a few different materials. The software will give you a good place to start. I created a Free CNC calculator to help sort a delicate balance between Feed Rates, Chip Loads, Spindle Speed, and Power that go into finding a CNC setup the optimizes .We offer both that free online drill feeds and speeds calculator using simple shop formulas, and also a free (for a limited time) full-featured calculator that is the industry leading speeds and feeds calculator. In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific operation and machine.

Please follow these steps to see if it works for you, Step 1 - Type in Feed rate in in/min (mm/min will be calculated from it) Step 2 - Pick the suggested chip load based on your material type and tool diameter.Feed Rate Calculator. When milling or drilling, or creating a tool path for a CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of cutter. The harder the material the slower the speed.Most machine controllers allow you to adjust the feed rate while a program is running and by listening to the sound the cutter makes this can be a good way of optimizing the parameters. Feed rate is calculated using the following equation: Feed = N .The Best Online Speeds and feeds calculator. For Milling, Turning, Drilling, Grooving, and Parting off. Results: Cutting conditions and Grades

Determine the spindle speed (RPM) and feed rate (IPM) for a drilling operation, as well as the cut time for a given cut length. Drilling operations are those in which a cutting tool with sharp teeth, such as a twist drill, rotates and feeds into the workpiece axially, forming a hole with a diameter equal to that of the tool.

A good starting point for drilling steel with a HSS drill bit would be 75 SFM with a feedrate of .001/tooth or .002” per rev. For aluminum I would use 130 SFM and keep the feedrate at .002” per rev, at least initially.

Speeds and Feeds Calculator This software can be used to determine the cutting parameters for a few different materials. The software will give you a good place to start. I created a Free CNC calculator to help sort a delicate balance between Feed Rates, Chip Loads, Spindle Speed, and Power that go into finding a CNC setup the optimizes finish quality and minimizes the time required.We offer both that free online drill feeds and speeds calculator using simple shop formulas, and also a free (for a limited time) full-featured calculator that is the industry leading speeds and feeds calculator. In this guide, I’ll provide a strategy for calculating your feeds and speeds that uses the formulas for a starting guess and then modifies the numbers based on your specific operation and machine.

Please follow these steps to see if it works for you, Step 1 - Type in Feed rate in in/min (mm/min will be calculated from it) Step 2 - Pick the suggested chip load based on your material type and tool diameter.

Feed Rate Calculator. When milling or drilling, or creating a tool path for a CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of cutter. The harder the material the slower the speed.Most machine controllers allow you to adjust the feed rate while a program is running and by listening to the sound the cutter makes this can be a good way of optimizing the parameters. Feed rate is calculated using the following equation: Feed = N .The Best Online Speeds and feeds calculator. For Milling, Turning, Drilling, Grooving, and Parting off. Results: Cutting conditions and Grades

Determine the spindle speed (RPM) and feed rate (IPM) for a drilling operation, as well as the cut time for a given cut length. Drilling operations are those in which a cutting tool with sharp teeth, such as a twist drill, rotates and feeds into the workpiece axially, forming a hole with a diameter equal to that of the tool.

A good starting point for drilling steel with a HSS drill bit would be 75 SFM with a feedrate of .001/tooth or .002” per rev. For aluminum I would use 130 SFM and keep the feedrate at .002” per rev, at least initially. Speeds and Feeds Calculator This software can be used to determine the cutting parameters for a few different materials. The software will give you a good place to start.

feed rate calculator cnc

Dive into our online wholesale junction boxes products catalog on globalsources.com! Source over 699 junction boxes for sale from manufacturers with factory direct prices, high quality & fast shipping.

8mm drill bit for cnc machine feed rate|feed rate calculator cnc