5 axis cnc machining pdf Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large . Wiley Metal Fabricating Inc is located at 816 W 34th St in Marion, Indiana 46953. Wiley Metal Fabricating Inc can be contacted via phone at (765) 671-7865 for pricing, hours and directions. Contact Info

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

RFID blocking materials create a barrier to stop scanners from accessing your cards or passports. Common options include metals and special fabrics that block signals and .

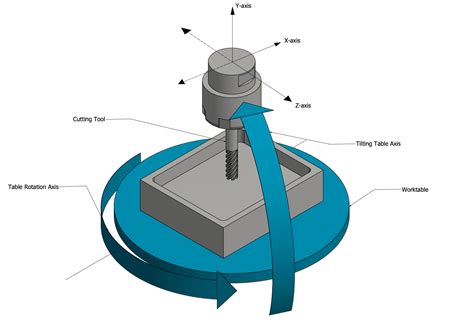

Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large .Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional . CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surface

Indexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining .Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limitsTake a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, .

A axis is equipment swing arm, C axis is equipment turret, to clamp.Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw .

True 5-axis machining involves moving the part or the cutting tool along five different axes simultaneously. The most commonly used axes in CNC machining are the linear X, Y & Z .With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large amount of data about the machining process and it all must be readily available to the operator.

what is 5 axis milling

Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional axes of rotation. Most machine tool builders identify their rotary axes according to the ISO standard, which is that: • The A axis rotates around X CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surfaceIndexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining (see below) in terms of speed, precision, and the ability to handle complex geometries.Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limits

Take a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, and once using the contemporary 5-axis part-centric workflow.A axis is equipment swing arm, C axis is equipment turret, to clamp.

Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw out maximum performance. With just a touch probe and datum sphere —auto tuning completed.

True 5-axis machining involves moving the part or the cutting tool along five different axes simultaneously. The most commonly used axes in CNC machining are the linear X, Y & Z-axes, but while 5-axis machining moves the tool back and forth (x-axis), in and out (y-axis), and up and down (z-axis), it can also rotate the part or tool at the same .With multi-axis machining, the main objectives are to achieve perfect surface quality, precision, and speed without any need for remachining. Within this context, workflow is typically character-ized by the CAD-CAM-CNC process chain.Modern machine tools, including the increasingly popular 5-axis machining center, place exacting demands on the CNC for exceptional speed, precision, and reliability. The CNC holds a large amount of data about the machining process and it all must be readily available to the operator.

Simplified 5-Axis Machining dptechnology.com 2 white paper What is 5-axis machining? Standard machines have linear motion along the X, Y and Z axes. 5-axis machines have two additional axes of rotation. Most machine tool builders identify their rotary axes according to the ISO standard, which is that: • The A axis rotates around X CNC Functions for 5-axis Machining. Fine Surface Finish. Smooth Tolerance + Control: • Smoothing tool center point (different algorithm) • Great for cutting 3D free surface

Indexed 5-axis machining is great for fabricating components like housings, jigs, and fixtures. The process falls somewhere between 3-axis CNC milling and continuous 5-axis CNC machining (see below) in terms of speed, precision, and the ability to handle complex geometries.Programming dynamic 5-axis machining directly in SINUMERIK Operate Basics, possibilities, and limits

what does 5 axis mean

Take a high-quality 5-axis machines with exactly the same CNC hardware and basic software. Process the same example part, once using the traditional 5-axis machine-centric workflow, and once using the contemporary 5-axis part-centric workflow.A axis is equipment swing arm, C axis is equipment turret, to clamp.Automatic tuning of a total of 11 different kinds of geometric error, including spindle misalignment and inclination. The accuracy of 5-axis machines is measured in less than 10 minutes to draw out maximum performance. With just a touch probe and datum sphere —auto tuning completed.

precision ceramic machining manufacturer

precision cnc machining cape coral fl

For a more modern take, choose a glass and stainless steel bread box. This style matches any decor for versatility when you refresh your cooks' tools or accents. With bread holders to meet every type of demand and interior design, you'll be glad you started using one.

5 axis cnc machining pdf|5 axis trunnion machining