making a box using harbor freight sheet metal bender You may not have to anchor that bender to the floor if you don't want to. I had the floor model like yours but didn't want to dedicate the floor space for it so I mounted it on the side of one of my benches and it works great. If . When it comes to screw size for a metal electrical box, several factors come into play, including the type of application and the weight it needs to support. The most common screw size for metal electrical boxes is #6-32, which is suitable for standard outlets and switches.

0 · welding sheet metal boxes

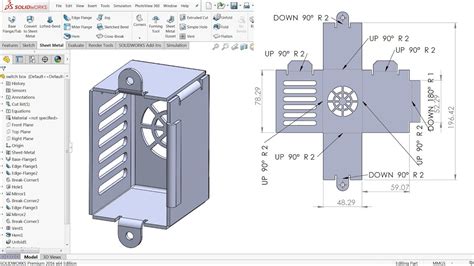

1 · sheet metal box instructions pdf

2 · how to make sheet metal boxes

3 · how to cut sheet metal box

4 · how to bend sheet metal box

5 · harbor freight metal bending brake

6 · folding sheet metal box instructions

7 · clarke harbor freight bender

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

welding sheet metal boxes

Got myself a metal bender - it’s the Clarke CCB1B bench mounted model and in fairness I quite like it. But I found the manual to be a bit lacking so I thought I’d set out to try and explain.In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .As the knobs are tightened, the spring compress into the recesses and the hold-down bar can provide full contact for clamping down thin sheet metal. See my . Using My Harbor Freight 20 Ton Press To Bend Metal. With this setup, you can bend 90-degree bends in metal. On the bender I made I can bend 1/4 inch metal that is 9 inches wide with no.

You may not have to anchor that bender to the floor if you don't want to. I had the floor model like yours but didn't want to dedicate the floor space for it so I mounted it on the side of one of my benches and it works great. If .The surfaces of the tool are heat-treated and hardened to provide a long service life.Watch video7:12I review this fantastic 30 Bending Brake from Harbor FreightAuthor: Jeep Creep It currently sells for 9.Handles sheet metal as thick as 20 gauge mild steel; Adjustable finger-dies for pans and boxes of varying sizes; Slip roll forms . Today we n the Harbor Freight compact bender through it's paces while bending some shepherd hooks to use as steel target hangers. This compact bender has com.

I purchased a 30" metal bending brake from Harbor Freight (model 67240) for a small project I needed to complete. I had read pretty good reviews about the brake, which cost .95. Overall, the quality looked decent when I opened . Just a quick little demo of the Harbor Freight 18" bending brake. I'm using this for the aluminum and sheet metal used in building the Belite UltraCub.Check out the Woodwardfab compact, shop friendly 12” Box and Pan Bench Top Brake! With an adjustable head for bending aluminum and 5 removable fingers make b.About this item. Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a .

Review and test of the capacity of the Harbor Freight 18" Sheet Metal Brake.can be used for varying sizes of box and pan forming. When forming a smaller box or pan, choose the desired size Upper Die, center it and remove the others. 2. The Shear Brake Roll can be used to bend sheet metal up to 20 gauge. 3. The space between the Upper Die and the Apron (11) is adjustable. 4. To adjust the spacing: a. Wonder anyone built a decent rollcage out of harbor freight tube bender? thanks in advance for sharing any experience u had done with the cheapo communist built tube bender. '91 YJ, 4.0, 1.5 RE SOA, 4:1, trussed 8.8, HP44, Detroit F/R, 4.88, Hydro assist, 37", Gibson header, custom cage, Hy steer, one ton TRE, Centerforce Dual Friction clutch

Warning: When using the Bending Brake keep fingers clear of the Supporting Plate and Moving Plate to avoid personal injury. 6. When the Bending Brake is not in use, it should be covered and stored in a dry location. Part Number Listing REV 06/02 REV 11/06 Part # Description Qty 1 Base Assembly 1 3 Pressing Plate 1 6 Handle Lever 2the work area during use. 5. Using both hands, lift up on the Body using its Lower Handles until the desired angle is reached on the workpiece. Once bend is complete, return Lower Handles to their down position. 6. Lift the upper Eccentric Handles all the way up and remove the sheet metal. CAUTION! During bending, keep both hands on the Lower .

DIY Sheet Metal Bender Brake Fully Modified: At a previous instructable, we had seen the build of a simple version, Sheet Metal Brake. The brake works pretty good but, has some limitations. The thickness of bending material can't be over 1mm. Has difficulty at bends that is too close to edge .

Benefits. When it comes to working with metals, having the right tools can make all the difference. A Metal Bending Brake from Harbor Freight can provide numerous benefits to your metalworking projects. Let’s take a look at some of the key advantages of using a metal bending brake for your next project.

This item has been tested to certify it can ship safely in its original box or bag to avoid unnecessary packaging. . KAKA INDUSTRIAL W-3018 Sheet Metal Bending Brake 30-Inch Length Portable Metal Bender 0-90 Degrees Adjustable Steel Bender, 20 Gauge Mild Steel and 16 Gauge Aluminum Metal Bending . I could have gone down to Harbor Freight .

About this item. Mini Sheet Metal Brake: The maximum bending width of the box and pan brake is 48 inches / 1220 millimeters. Upgraded with a 0.31" thick blade and reinforced rib design, this product achieves excellent bending results, . I am contemplating the idea of making a sheet metal brake. I don't know much about bending sheet metal but I have made some small projects (boat console and some other things) with a cheap brake from Harbor Freight. With . Hello Everyone!Today I show you how to make a metal bender. This one is a roller bender type metal bending machine. This homemade roller bender is very simpl.I built my own, heavy dut.This is a wide sheet metal brake that needs only 4 materials to build: an angle iron, square tube, a flat stock, and a hinge.Building Instructions.Tags:DIY Sheet Metal BrakeSheet Metal Brake How To UseSheet Metal Bending Brake Clamp the wood on the top of the metal to the workbench.A press brake is a versatile tool .

I'm looking to make a metal box enclosure from aluminum sheet metal that is 3/32" thick. the final box will be about 1.5x2' (with 0.5' depth) in size with corners that have a 2" radius. sheet metal will be 0.5'x8' in size, so pretty manageable. it will need to be bent for the four corners and then one tig weld to join them up. this is a simple illustration of what it will look similar too.

sheet metal box instructions pdf

DIY Sheet Metal Bender Brake Fully Modified: At a previous instructable, we had seen the build of a simple version, Sheet Metal Brake. The brake works pretty good but, has some limitations. The thickness of bending material can't be over 1mm. Has difficulty at bends that is too close to edge .1. Make sure the Crank Handles (2, 16) are all the way down before opening the upper Upper Press Plate (10). 2. On the stock, draw a straight line with a pencil to indicate the intended bending point. 3. Slide sheet metal to be bent between the Bending Leaf (18) and the Upper Press Plate (10). Align the drawn bending line on the stock with

**Note: 1:30 I said 1/4 x 2 x 36. It's 1/4 x 3 x 36 for the angle iron welded to the stock bar.These modifications greatly improved the use of a basic 30" be. KF5006 Box and Pan Brake Sheet Metal Folder Bending Brake Metal Forming Machine Max Capacity 24 Inch (610mm) 20 Ga (1.0mm) with 5 Fingers 0-135 deg . Visit the KASTFORCE Store. 4.6 4.6 out of 5 stars 24 ratings. 9.98 $ 399. 98. Delivery & Support Select to learn more . Ships from Amazon .Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you! . 12 Ton Hydraulic Pipe Bender. 12 Ton Hydraulic Pipe Bender $ 149. 99. Add to Cart Add to List. CENTRAL MACHINERY. 44 in. Telescoping Handle Compact Bender. 44 in. Telescoping Handle Compact .Make smooth, precise bends in sheet metal up to 36 in. wide. The adjustable press plate lets you make sharp or round bends up to 0 - 120°. . MB-36). Save 0.00 by shopping at Harbor Freight. Shop Now for Item 62518. CENTRAL MACHINERY 36 in. Metal Brake with Stand - Item 62518 / 62335 / 87384 / 91012. Shop by Department. Automotive .

This 3-in-1 roll machine also includes adjustable finger dies for pans and boxes of varying sizes making this unit essential for any metalworking shop. Shear makes straight cuts and bends up to 30 in. wide with adjustable stops from 1/2 in. to 16 in.

antique metal shelf brackets

Painting a metal door can be done successfully by any do-it-yourselfer armed with some knowledge and a roller. Because of the materials, some of the steps are different than painting a wooden door, but that won’t .

making a box using harbor freight sheet metal bender|welding sheet metal boxes