what is metal fabrication engineering Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, . Boxes that are designed to support ceiling fans must be labeled as such, and must have a label listing the weight it can support if over 35 pounds (NEC 314.27(D)). If you look at the box you have, you'll notice a flat bit within the box.

0 · types of sheet metal process

1 · types of sheet metal fabrication

2 · metal fabrication process flow chart

3 · metal fabricated products

4 · fabricated metal products manufacturing

5 · different types of metal fabrication

6 · custom metal fabrication shop

7 · basic metal fabrication

Set the Smoker Box right on top of your cooking grates to transform any gas grill into a smoke cooker to give your meats, veggies, nuts, and cheeses the mouthwatering smoky flavor you crave. The weather resistant Fuel Storage Bag keeps your wood pellets or charcoal dry and BBQ ready!

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves . Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .Fabrication is the process of constructing products by combining typically standardised parts using one or more individual processes. For example, steel fabrication is the production of metal structures using a range of processes .

Metal fabrication plays a vital role in engineering, transforming metal into functional components of everyday life. It’s a precise blend of science and skill, where raw materials are crafted into . Metal fabrication consists of processes used to produce products, components and structures from raw metals. Item or items created by these processes are often known as . Fabrication engineering is the process of manufacturing metal-based structures from raw materials using techniques such as cutting, forming, shearing and welding. People . Metal fabrication is the process of producing metal elements from raw materials through actions like cutting, bending, welding, machining, and assembling. Many tasks are now automated, with precision machinery .

Metal fabrication is a critical component of various industrial processes, from manufacturing to construction, and plays an essential role in the development of customized vessels and piping . Metal fabrication is a process that is a big part of a lot of products and appliances that regular people use in their day-to-day life. This article attempts to present some basic information about metal fabrication, its different types, methods and so on. . Since a large part of the sheet metal engineering process relies on various semi . What Is Metal Fabrication? Metal fabrication consists of processes used to produce products, components and structures from raw metals. Item or items created by these processes are often known as fabrications. Manufacturing companies perform metal fabrication using a combination of manual and automated processes.

Custom fabrication metal is literally called the entire process of manufacturing raw metal materials together with machine parts and structural components. These processes mean that everything from cutting and forming to final assembly is .Education: To become a fabrication engineer, individuals typically start by pursuing a bachelor’s degree in mechanical engineering, materials science, or a related field. This formal education provides them with a strong foundation in engineering principles and materials science. Hands-On Experience: Many fabrication engineers gain practical experience through internships or entry . Metal fabrication is the process of transforming raw metal materials into finished parts or structures. It includes cutting, welding, machining, and assembling to create products used in various industries, such as construction, automotive, and aerospace.

Sheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Various special tools are used in this process to convert sheet metals into useful components by minimal efforts. It is a value-added process to create machines, structures, or component parts following engineering drawings which usually serves as the . Metal Fabrication and Engineering From Aranda Tooling. The metal fabrication industry will continue to grow and impact other industries in the coming years. At Aranda Tooling, Inc., we provide high-quality metal fabrication and engineering to a variety of critical industries around the world. Our team of approximately 300 skilled professionals . Explore the world of metal fabrication and discover why it's a hidden gem for career seekers. From building spacecraft components to earning above-average salaries without a college degree, find out the five compelling reasons metal fabrication might be the perfect fit for your skills and ambitions. Start your journey in this dynamic field—no suit and tie required! Whether it is crafting intricate parts for machinery or conducting repairs, metal workshops are essential hubs for precision manufacturing and metal fabrication. What is metal work engineering? Metalwork engineering is a discipline dedicated to mastering the art of working with metal, including techniques such as cutting, shaping, and welding.

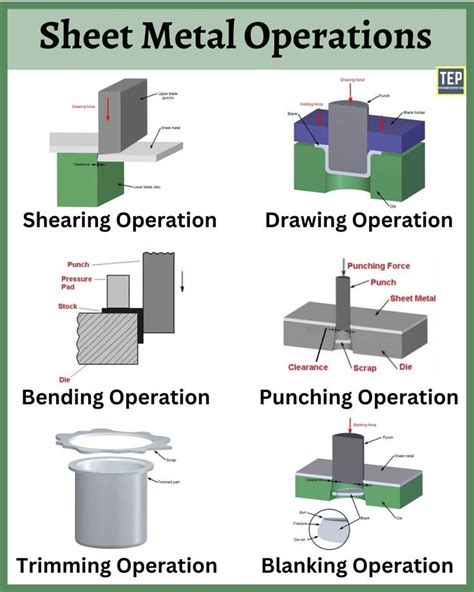

types of sheet metal process

Take your steel fabrication project from concept to completion with Carver Engineering. When it comes to steel fabrication, Carver Engineering is equipped to handle every stage of your project, from detailed design to delivering components ready for installation. With state-of-the-art plasma cutting technology and a highly skilled team, we .Metal fabrication is a process that involves the shaping of raw materials into finished products. It necessitates a high degree of skill and knowledge, as well as experience in the industry. The end result is often something that is both aesthetically pleasing and highly functional. Custom metal fabrication can be used to create allMetal fabrication is a broad manufacturing term referring to processes such as cutting, bending, and punching. It normally pertains to more labor-intensive practices with long production times. . Quality Metal Stamping Services from Engineering Specialties, Inc. If you require reliable sheet metal stamping services, the professionals at ESI .Working with a metal fabrication company can help engineers with the metal fabrication technology and design trends. This articles discusses tips for engineers on what they need to know about metal fabrication. Find the Right Fabrication Company . It's vital you find a fabrication company that is willing to work with you and provide the .

Sheet Metal fabrication is a manufacturing process where flat sheets of steel o. In this video, you'll learn what sheet metal fabrication is and how it works.

Metal fabrication is a process that involves shaping, cutting, and assembling metal parts to create structures, machinery, or components. It encompasses a wide range of techniques and methodologies, each tailored to .

Metal fabrication is an umbrella term used to describe the creation of a component, part or structure, out of metal. Metal fabrication typically involves manipulating raw materials, in the form of sheet metal, metal billets, bars or . What Is Custom Metal Fabrication? Custom metal fabrication is another generic term used to describe a certain set of several different material shaping techniques. Though the name is often shortened to simply “metal .

Fabrication is the construction of items from different parts using at least one of a range of processes and materials such as metal, laminates, wood and other solid surface materials. Frequently used in relation to metal fabrication, the steps involved can include stamping, welding, cutting, bending, and assembling processes.With these materials, fabrication engineers often work alongside architects and other engineers to create plans for everything from machine parts to buildings and bridges. In this article, the KNS Metals team explore steel fabrication engineering in more detail, including the different methods and applications. Steel Fabrication Engineering Methods

Tools. Students should review the Welding Tools & Supplies to determine what tools and supplies they will need to purchase. The Welding department realizes that some students may not need to purchase the entire list of supplies. These students may contact the School Office for guidance in purchasing their supplies. The College Store can provide the complete kit.

While every custom metal project is unique, some key elements are common across all fabrication jobs. These include: Design and engineering: Fabricators work with clients to interpret specifications into detailed plans. Material selection: A suitable metal alloy and thickness are chosen for durability, corrosion resistance, and more. Cutting and machining: .

Types of Metal Fabrication Processes. The journey from sheet metal to metal products starts with CAD engineering. After making the models, each part goes through the necessary sheet metal fabrication processes. The most common ones are: Thermal Cutting. Laser cutting is the preferred option for cutting sheets. Metal fabrication is the heart of the metal manufacturing industry. It encompasses numerous processes, materials, and an efficient workflow. . Without it, we would not create the components that keep our businesses, engineering, and vehicles functioning. In addition, an array of fabricated metal products can be seen in everyday life – from .Simply put, “metal fabrication” is defined as creating products or structures by cutting, bending, and/or assembling metal material. . Industrial fabricators typically serve industries such as aerospace, alternative energy, material handling, pollution engineering, water treatment, automotive, and more.

Metal fabrication is the process of creating an end product from raw metal materials. The process includes cutting, burning, welding, machining, forming, and assembly to create the final product. SRS has fast become one of New Zealand’s most trusted high-end metal fabricators, and it’s our end-to-end service that makes us such a great option for all your metal .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. Sheet metal is highly compatible with the process, allowing custom sheet metal fabricators to create diverse products with optimal design versatility and .

What Does the Metal Fabrication Process Look Like? While the primary focus of metal fabrication is cutting and shaping metal, there are several key steps involved in a typical project. Here’s an overview of the process: Designing the Project. The first step in metal fabrication is designing the part or product.

ventilated electrical enclosure

types of sheet metal fabrication

I'll drill a drain hole in all enclosures, we get condensation from the moisture out of conduits. Drain holes are allowed now by the 2014 NEC. The breather by Hoffman is a good solution, but also should consider sealing conduits with duct seal or similar.

what is metal fabrication engineering|custom metal fabrication shop