stamped sheet metal part estimator The Metal stamping process enables the creation of components with diverse shapes, including bends, curves, cutouts, and embossing. Furthermore, it maintains consistent quality, dimensional accuracy, and . Find Steel angles, brackets & braces at Lowe's today. Shop angles, brackets & braces and a variety of hardware products online at Lowes.com.

0 · sheet metal stamping cost

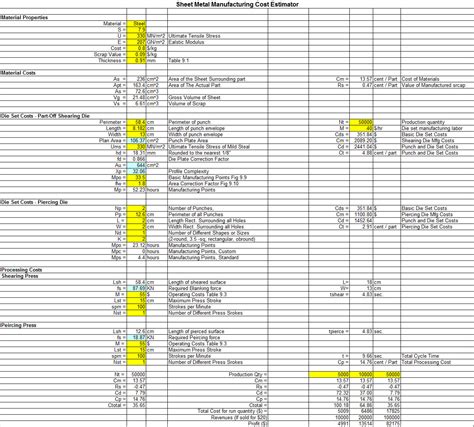

1 · sheet metal production cost calculator

2 · sheet metal parts cost estimator

3 · sheet metal manufacturing cost estimator

4 · sheet metal fabrication estimate

5 · metal stamping cost calculator

6 · cost estimating software sheet metal

7 · cost calculator sheet metal

Buy Steel Window Box Brackets at Walmart.com. Home Improvement /; Hardware /; Brackets and Angle Irons /; All Brackets and Angle Irons

Costimator contains hundreds of fabrication process cost models that make estimating sheet metal parts and assembly a breeze. Users that have access to 3D models can utilize the system's 3Dfx tool to: UTILIZE 3DFX & CAD TO . The Metal stamping process enables the creation of components with diverse shapes, including bends, curves, cutouts, and embossing. Furthermore, it maintains consistent quality, dimensional accuracy, and .Calculate metal stamping cost per part and get custom stamping cost estimation accurately. With comprehensive stamping cost analysis, optimize your manufacturing expenses. A) General Part InformationUse the many interactive tools to aid in the design and manufacture of your part. These tools provide a fast and reliable way to identify a compatible process and material, estimate the cost .

Paperless Parts offers a game-changing solution to the challenges of estimating sheet metal fabrication costs. With their sheet metal cost estimation software, estimators can bid farewell to the days of manual data entry and .Sheet thickness (in): Die edge radius (in): Punch edge radius (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety:

Sheet metal stamping is used to form three-dimensional . Lovell et al. [1] estimate that over 0 billion is spent annually in the United States alone on the design, fabrication, and assembly of stamped parts. . when predicting the energy required to form a part. No holistic analysis on sheet metal forming costs has been found in the .

While international suppliers may offer what appear to be lower per part prices for metal stamping – the cost of troubleshooting production issues, low quality die maintenance, cost of shipping containers, delays at the ports, and geo-political .given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance from the form. This distance should never be less than the radius of the bend. Figure "C" shows a bend relief cut into the part, again the depth of the relief .I have a part which is a stamped sheet metal component (see example) that I want to 'flatten' in fusion so I can see what the profile needs to be for laser cutting (pre-forming). Obviously there are stretch considerations but I want to start with a near net shape profile to reduce the amount of trimming required post-stamping. We will need 7 sheets of material and produce 15 parts per sheet, except the last sheet with only 10 parts. Scrap estimation is 39.41%. If we make any changes to our component, sheet size, quantity, or offsets, we can quickly update our estimate. In this case, I’ve increased the width of the part and increased both the part and sheet offsets .

Estimating stamping piece costs is a challenge for nearly everybody in the sheet metal value stream. To bring sheet metal product to market, you rely on numerous cost estimates to prove that the product is worthwhile, win new projects, select suppliers, and ultimately assure your operation’s profitability. Cost estimating need not seem "mystical" Industry hasThe best stamped metal part designs take this step-by-step nature of the stamping process into consideration. . Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible. When such factors cannotAutoForm-CostEstimator is designed for OEMs and suppliers to estimate tooling costs early on in cost and value engineering, during procurement and bidding. It enables users to rapidly calculate tooling costs for sheet metal parts by allowing them to consider alternative stamping processes and detailed cost tracking. . based on 3D-CAD part .30 votes, 37 comments. I designed product containing ~60 sheet metal components and I need to do a rough estimation of the production BOM cost (100's.

A newly added quick-die-estimate feature allows users to go from part drawing to die price in 10 min. or less. Templates can be created to allow a quick estimate of similar dies in minutes, and reports can be generated with more than 800 die parameters.

Sheet metal fabrication is a crucial process in various industries, including automotive, aerospace, construction, and electronics. The ability to accurately estimate the cost and time required for sheet metal fabrication projects is essential for maintaining profitability . Peter U. FRI, JAN 29, 2021 @ 9:29 AM Hello Deryl. The wall thickness was an engineering requirement for the extruded hole. The premise of the example was based on the parameters described in paragraph 4: "The product designer requires an 8.2-mm ID and a minimum wall thickness of 1.5 mm., with a minimum 3.0-mm extrusion height (h).34 Sheet Metal Estimator jobs available in Minnesota on Indeed.com. Apply to Estimator, Project Estimator, Metal Fabricator and more! . Part-time; New. Encouraged to apply. filter. Location. Minneapolis, MN; Saint Paul, MN; . Duties of the sheet metal estimator:. Experience in metal stamping/fabrication.A network of suppliers are on Alibaba.com to fulfill your sheet metal part cost estimator needs at wholesale price. Whatever custom design you need, we have the sheet metal fabrication options to make it a reality. All categories. Featured selections. Trade Assurance. Buyer Central. Help Center. Get the app. Become a supplier.

Suppose that the design engineering team set the specifications for length of a stamped sheet-metal part at 10 inches (T) with acceptable tolerances of ±.05 inches (USL and LSL). The average length of the products produced by the actual stamping process is 9.995 inches with a standard deviation of .005 inches. These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD . Our experts at STAMPING Journal explain the calculation of tonnage when doing stamping calculations in progressive stamping. Learn more here. . This is visible on the edge of any stamped part. . EMJD acquires Proto Sheet Metal Products. 4. Sun Metalon relocates headquarters to Illinois. 5. Tool flips large, heavy plates and parts safely . Call the starting thickness of your sheet metal “S” and call the formed thickness of your part at the location of interest “F”. The percent thinning is calculated as T% = 100 * (S-F)/S. This is the actual percentage of material loss in a specific stressed area on your formed part.

We offer an online calculator, Metal Fabrication Price Calculator, to help you quickly determine cost of a fabrication project.It features: . Stamping. Deep Drawing. Sheet / Pipe Bending. Forging. Roll Forming. CNC Machining. Metal Cutting. Al Extrusion. Casting. Sand Casting.Progressive die stamping is an innovative manufacturing process where metal strip is fed through multiple stations in a die to progressively shape and cut the materials into precise parts. It is commonly used to build custom parts like hinges, latches, brackets, panels, automotive components. Our advanced stamping cost calculator provide reliable pricing insights.

Hi all, Does the Fusion 360 sheet metal workspace have tools for created impressed/formed sheet metal parts? For example, if I wanted to press in some text on a sheet metal part. I can do a simple extrude and filet but this does not cause the metal to come out on the other side. How do I create so that if I send the file to a manufacturer they will know to only .

/ Sheet Metal Solid Decorative Tread plate Expanded 1-ft 24-in 36-in 1/64-in 1/40-in 1/32-in 5/64-in Mill finished Oil rubbed bronze Anodized Bright Painted Clover leaf Tread plate Union jack Lincane Leather grain Hillman M-D Steelworks 4 5

Our diverse range of automatic stamping machines with press forces from 25 t to 250 t is capable of handling different grades of steel, carbon steel, stainless steel, aluminium and non-ferrous metal alloys in thicknesses from 0.15 to 4 mm. Our experienced workforce produces high-precision punched, bent and drawn parts on these machines.

The Stamped Sheet Metal Part is a key item within our extensive Stamping selection.Purchasing stamping machinery wholesale offers cost savings, bulk availability, and streamlined production processes. Wholesale deals often include discounts, after-sale support, and customization options to suit specific manufacturing requirements. . Area of focus System function Reasoning logic Dastidar (1991) Stamped part design Cost evaluation for part design CBR Poli et al. (1993) Stamped part design Cost evaluation for part design CBR .

The process of sheet metal stamping takes pieces of coiled or blank sheet metal and creates three-dimensional part shapes from them. In this process, the blank or coiled sheet is placed into a stamping press, in which the die (or stamping tool) in the shape of the part desired is pressed into and through the material to form the part.

amada cnc turret punch press machine

sheet metal stamping cost

sheet metal production cost calculator

$49.99

stamped sheet metal part estimator|cost calculator sheet metal