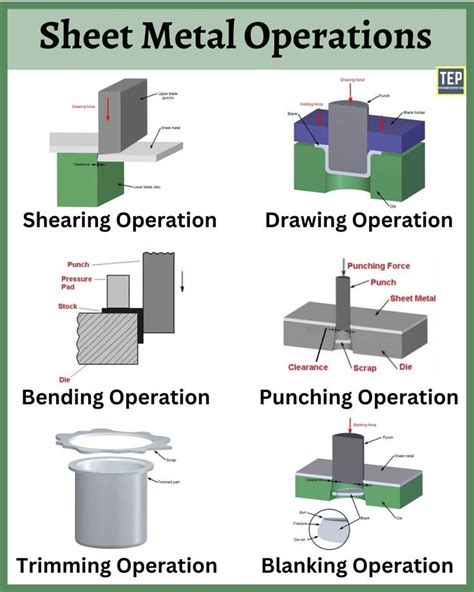

sheet metal fabrication definition What is sheet metal fabrication, exactly? It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms. It involves a combination of cutting, bending, .

You can use a standard rectangle single gang box, an octagon box, or a 4" round box. The choice is yours, but any of them will work just fine. The slots in the mounting plate allow this fixture to line up with a number of different box types.

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal manufacturing process types

4 · sheet metal manufacturing guide

5 · how to fabricate sheet metal

6 · how is sheet metal manufactured

7 · basics of sheet metal fabrication

Especially with panels. 4x4 boxes that have the recessed ground screw spot. They make self-taping screws that do this. Used on car sheet metal for decades. The screw tip is a .

various sheet metal processes

Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional .Sheet Metal: Refers to the raw material itself—a flat, thin piece of metal, often used as a starting point in various manufacturing processes. Fabrication: Represents the series of processes used to manipulate and transform raw .

perforated metal sheet pattern

Sheet metal fabrication is the process of forming, cutting, and assembling metal sheets into functional products. It involves several stages including cutting, bending, and joining. The versatility of sheet metal allows for . The definition of metal fabrication and types of fabricated products. As a process, metal fabrication is all about creating various metal structures using different processes using . Sheet metal fabrication refers to the turning of flat metal sheets into metal products and structures. Typically, this technique involves transforming different types of sheet metals into parts and components.

What is sheet metal fabrication, exactly? It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms. It involves a combination of cutting, bending, .This guide provides a complete look at sheet metal fabrication, its advantages and disadvantages, cost considerations, key design factors, and more. How Does Sheet Metal Fabrication Work? At its core, sheet metal fabrication involves .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .Sheet metal fabrication encompasses a variety of processes that work in tandem to transform flat metal sheets into complex structures. These processes include cutting, bending, welding, and finishing. Sheet Metal Fabrication: Sheet metal fabrication involves forming and manipulating thin sheets of metal, commonly used in various industries. HVAC Systems: Crafting ductwork and other components for heating, .

Practical issues for sheet metal fabrication. A number of important characteristics of a sheet metal product cannot yet be universally recorded in the STEP AP242 protocol. Dutch consultant Ton Derksen has conducted . Definition of sheet metal. While no universally accepted definition of sheet metal exists, industry consensus generally characterizes it as follows: Sheet metal refers to thin, flat metal material, typically less than 6 mm (0.25 .What is Sheet Metal? Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a .In our last blog, Metal Construction Industry 101 looked at the fundamentals along with the current and emerging trends. Continuing the conversation now with metal fabrication, another key fundamental process in the metal construction industry. Globally it is valued at over 20 billion in 2022 and poised to grow to over 31 billion by 2031!. The metal fabrication industry is an .

Basics of Sheet Metal Dimensions Definition of tolerances in sheet metal fabrication. Tolerances are at the core of all our sheet metal fabrication work. What exactly are tolerances? Tolerances are the acceptable range of variations in the dimensions of sheet metal parts that we manufacture.Sheet Metal Fabrication Definition Introduction to Sheet Metal Fabrication. Sheet metal fabrication. It may sound like a complex and mysterious process, but it’s an essential manufacturing technique that plays a significant role in countless industries. From automotive to aerospace, construction to electronics, sheet metal fabrication is the .Metal fabrication is the process of building machines and structures from raw metal materials. It involves cutting, bending, and assembling processes, which convert metal sheets, bars, and tubes into desired shapes and sizes. High definition CNC plasma cutter is a type of 5x10 Hypertherm plasma table kit for custom sheet metal fabrication of aluminum, steel, copper, iron, alloy in machinery, automobile, metal parts, ship building, war industry, metallurgy and more.

Major Types of Sheet Metal. Aluminium: Used for automotive parts, electrical devices, and cooking vessels.Offering numerous benefits including a good strength-to-weight ratio, and high conductivity. Aluminised steel: This metal combines the high strength of carbon steel with aluminium’s superior corrosion resistance.Sheets of aluminised steel are used for products . The definition of metal fabrication and types of fabricated products. As a process, metal fabrication is all about creating various metal structures using different processes using both manual labor and automation. . Here are some of the biggest advantages of sheet metal as a fabrication material:Definition. Sheet metal fabrication is the process of transforming flat sheets of metal into functional components through various manufacturing techniques like cutting, bending, and assembling. This technique is essential in creating parts for a wide range of industries, including automotive, aerospace, and construction. .

A Sheet Metal Worker, or Sheet Metal Technician, works with thin sheets of metal to produce and install various types of products. On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, . This article will delve into the definition, processes, types of techniques, material selection, surface treatment options, design considerations, and DfM techniques in sheet metal fabrication, and explore why top-tier sheet metal manufacturing parts manu. Cookies +86 15099911516 [email protected] 14 years one-stop China custom CNC machining . Sheet metal fabrication is the process of transforming flat sheets of metal into specific shapes and structures through cutting, bending, and assembling techniques. It’s a crucial method in manufacturing, widely used across industries such as construction, automotive, aerospace, and electronics, to create durable and precisely engineered .What is sheet-metal-fabrication? Definition for sheet-metal-fabrication in construction & building - Construo - The Construction Business Network

Sheet metal fabrication is a transformative manufacturing process that reshapes thin, flat pieces of metal into a variety of components and structures that are vital across different industries. The process involves selecting a . Learn about Sheet Metal Fabrication. Definition and importance of sheet metal fabrication in various industries. Understanding of materials, design considerations, cutting, bending, joining techniques, and quality control in sheet metal fabrication. Emerging trends and advancements in the field.This can be crucial for quality control, inventory management, and tracking the lifecycle of parts in sheet metal fabrication. Go Back. View Glossary. Taichung City, Taiwan; View E-mail +886-4-2350-0999; Get In Touch. Services. Product Design Service. Laser Cutting. Bending. Welding. Assembly. Case Studies. Latest News. About Us. MIG (Metal Inert Gas) welding or Gas Metal Arc Welding (GMAW) is a process in which a welding gun feeds a wire electrode, which melts and serves as the filler material between steel parts. The welding gun also emits a shielding gas like Argon or CO2 to prevent contamination or oxidation from the surrounding air.

Sheet metal forming is a sheet metal fabrication process that manipulates metal into flat sheets into complex shapes. Employed extensively across various industries, this technique involves a range of operations such as bending, drawing, and punching. . Metal Cutting Process: Definition, Types & Applications What is Metalworking: Definition . Sheet metal fabrication encompasses a variety of processes used to transform flat metal sheets into complex shapes and structures. It typically begins with the cutting of metal sheets to the required size. . High-Definition Plasma: Employs a secondary gas flow to constrict the plasma arc, resulting in a narrower kerf and improved cut quality .

Sheet Metal Basics Definition of Sheet Metal. In its simplest form, sheet metal is a thin, flat piece made from the more prominent metal roll. The metal sheet is uniformly thin, no more than 6mm thick. . Automation and Robotics for Sheet Metal Fabrication. Automation and robotics are increasingly used in our industry to achieve efficiency and . Let’s explore the definition of tolerancing, the difference between precision machining and sheet metal fabrication tolerances, and how to rectify the common problem of overtolerancing parts. What Is Tolerancing in Manufacturing?

Sheet metal parts are components made from metal sheets fabricated to specific shapes and sizes, commonly used in various applications across industries like . Integrated Sheet Metal Fabrication & Assembly of a Complex Coffee Roaster. September 23, 2024; Services Product Design Service Laser Cutting Bending Welding Assembly. Case Studies . With aerospace sheet metal fabrication services, raw metal materials become key components for aircraft and other parts used within the aerospace industry. It is a demanding service, for an industry in which every piece, no matter how small, has to meet strict standards and remain at the highest levels of quality and functionality.Definition of metal fabrication in the Definitions.net dictionary. Meaning of metal fabrication. What does metal fabrication mean? . or even yet more bending in the form of a crimped seam. Structural steel and sheet metal are the usual starting materials for fabrication, along with the welding wire, flux, and fasteners that will join the cut .

types of sheet metal process

types of sheet metal fabrication

pensacola metal fabricators

sheet metal manufacturing process types

Discover step-by-step considerations for planning your metal building's foundation and explore various foundation options in this article. Learn how factors like land quality, load distribution, wind uplift, and more impact your foundation choice.

sheet metal fabrication definition|various sheet metal processes