what parts does a cnc lathe use CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or .

Mount these boxes to the outside of an enclosure to access a programmable logic controller or other networked device without opening the enclosure. With built-in threaded connections, these boxes allow you to attach conduit without using fittings. Close off unused outlets. Designed for commercial use, these heavy duty boxes have thick, rigid walls.

0 · haas cnc parts catalog

1 · cnc replacement parts manufacturer

2 · cnc machine parts list pdf

3 · cnc machine parts catalog

4 · cnc lathe replacement parts

5 · cnc lathe parts list

6 · cnc lathe parts catalog

7 · cnc lathe headstock

Comparison Chart: Bed size: Full Mainstays 7.5" Quad-Fold Metal Box Spring, Full: .

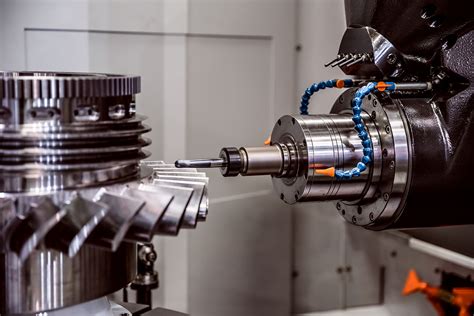

An in-depth examination of the 9 integral parts of a CNC lathe machine, exploring their functionalities, significance in the machining process, and insights into their evolution over time.

This article will focus on defining CNC lathes, identifying the lathe machine’s parts, examining how each element works, and advising about optimal use. Here is an image of how a CNC lathe looks with major parts labeled: .Here, we will explore the main components that make up a CNC lathe machine. We will take a closer look at the bed and headstock, tailstock and carriage, chuck and spindle, tool turret and .

If you’re in need of a quick rundown, here are the main parts of a CNC lathe: Headstock. CNC Lathe Bed. Chuck. Tailstock. Carriage. Tool Turret. CNC Control Unit. Coolant System. CNC . CNC lathes are specifically well-suited for manipulating cylindrical parts, while mills can be utilized for flat, curved, or angular components. CNC .

CNC machines come in many different configurations, but the most common are CNC mills and CNC lathes. CNC lathes are better suited to processing cylindrical parts whereas mills can be used on flat, curved, or . The main components of a CNC lathe include: Bed: The bed is the base of the machine, and provides a foundation for the other components. It is usually made of cast iron and provides a stable platform for the lathe’s moving . A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the .Sep. 09, 2023. 8 Parts of a CNC Lathe Machine. A CNC lathe is a fully automated machine capable of precise turning and drilling operations. It follows G-code programming intended for .

Generally the left one is used for clamping and declining of chuck and the other one is used for clamping and declining of taste dock. This guide will help you to familiarize what are the different parts of CNC lathe and what are .

I have a preferred budget of around 7000 (maximum 9,000) and I would not mind getting a used mill/lathe to machine the engine internals. The trouble is, CNC mills used to machine engine internals are in the 70k-100k range which is way outside my budget, so would machining my own parts with the budget I have even be feasible?The Tsugami SS26 stands out as a CNC lathe offering precision in turning operations. Sought after in various sectors like aerospace, medical, and automotive, it crafts intricate parts like shafts and bushings. This CNC lathe is adaptable to numerous materials, enhancing its utility across different production needs. seriously consider cnc swiss for that range of parts, bad part of a cnc swiss is no chance to go bigger like a regular chuck type lathe. I have a 12 inch chuck machine that does ok down to about 3/8, but prefers in the 5/8 and up range plus a cnc swiss.

To determine the parts of a CNC lathe machine, it is recommended to study the user manual and breakdown images of your machine. You should have a clear understanding of each component before progressing to cutting metal. The descriptions of machine elements (headstock, chuck, lathe bed, etc.) are generic. Nomenclature and layout may vary .

This is a lathe. I do not plan on making parts for NASA, but I want to be able to turn, face and bore things like wood, brass, aluminum and plastics. . Part STORE Builds > CNC LATHE BUILDS > About Us The OpenBuilds Team is dedicated helping you to Dream it - Build it - Share it! Collaborate on our forums and be sure to visit the Part Store . A CNC lathe turret is a component used in a lathe machine that holds and indexes the cutting tools. It is responsible for changing the tools and bringing them into the cutting position. This automated process is efficient and fast, allowing for a high level of precision in the manufacturing process.Examples include wheel lathes for railroad maintenance or crankshaft lathes for engine manufacturing. How do I choose between a manual and a CNC lathe? Consider factors like production volume, part complexity, required precision, and budget. CNC lathes are better for high-volume, complex parts, while manual lathes offer flexibility for low .Study with Quizlet and memorize flashcards containing terms like Which must be set first? a. Geometry Offset b. Work Offset c. Wear Offset d. Radius Offset, What does feed measure on a CNC Swiss-type lathe? Feed measures the: a. Distance the cutting tool travels before reaching the workpiece. b. Distance the cutting tool penetrates the workpiece. c. Rate at which the .

Types of CNC’s Used: CNC Lathes; CNC Mills; 10. Agriculture Industry: The agriculture industry uses CNC machines to make important parts. CNC mills are precise shapers, making components like tractor parts and pieces for irrigation systems. CNC lathes are like sculptors for cylindrical parts, crafting things like irrigation system components. Best Upgrade for CNC Lathe Machine Parts. The best upgrade for CNC lathe machine parts varies depending on user needs. A range of possible improvements can be considered depending on the quality of the lathe machine parts. Examples are: Improved Controller: Better controller hardware can improve capabilities and program editing. Non . CNC lathes have witnessed a remarkable technological evolution, progressing from manual machines to precision CNC systems. This journey represents a significant advancement in manufacturing. In the contemporary manufacturing landscape, CNC lathes play a pivotal role, in enhancing efficiency and ensuring consistent high-quality output. They .

leading cnc manufacturers

Hey r/Machining, I'm currently working towards a Machining Certificate and in my CNC lathe class recently we ran into an issue with a program.So in this program we were turning a little aluminum baseball bat, and at the handle end, there were some radii for the end of the handle. For even more advanced operations and greater part complexity, some CNC lathes utilize a fourth axis, known as the B-axis. The B-axis provides rotational movement and allows for off-axis machining. This axis is particularly useful for creating complex shapes, such as angled holes or off-center features. The first part is very easy to lathe, the "long" 4mm + 1.5mm has nothing to say about. . The tool geometry has to be good and the feed very regular- never tried on a CNC lathe, that has to be the tits. . If there's no way to do the part in one shot and you have to flip it, you are on the right track. . If you do parts with a long length to diameter ratio the tailstock is essential. J. Jashley73 Titanium. Joined Jan 24, 2013 Location Louisville, KY. Nov 23, 2013 . The CNC lathes like the mills have a tool path feature you can run to check tool paths right there at the control,this has caught many a flub up on my part before a crash happened.

I know zero about CNC but I understand that you can use the lathe as a manual lathe to do a single or small run of parts or you can use it as a CNC. I also read that you can machine a part and save the sequence for furture machining of the same parts. . The lathe will work as a manual or CNC lathe. The lathe does not work well for a manual . A lathe machine is a type of versatile machine tool used in CNC services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, . CNC lathes are one of the most common CNC machines on the market today. Lathes can be used to produce complex and detailed products from wood or metal. . Lathe Parts You Should Know. Control Panel (CNC): The instructions, programs, and machining software are all housed in the control panel. Operators control and manage the control panel to .

Main Parts of a CNC Lathe Machine. Image Credits: cnclathing.com. 1. Headstock. Headstock holds the feed controllers, gear train, speed control levers, and main spindle during the machining process. It is aligned with the tailstock and is made up of cast iron. The main spindle has a spindle drive system and spindle assembly.Study with Quizlet and memorize flashcards containing terms like Name the two primary machine axes on most CNC turning machines., Explain the difference between a turning center and a CNC lathe., List the three common types of live toolholders. and more. CNC lathe machine parts play an indispensable role in modern manufacturing, pushing the boundaries of precision and intricacy in products across various industries. At the heart of this manufacturing revolution is the CNC lathe.Lathes, historically used for centuries, have been transformed by computer numerical control, enabling greater accuracy and complexity .

How much power does a CNC machine need? If the machining time is half an hour and the feed rate is 500 mm/min, the power usage is 0.5 hr X 14.4 kWh = 7.2 kWh. . an electronic A.C. motor speed controller can be used in the lathe to save energy. Constant speed A.C. motors are suited for various applications in most equipment. Overloading, line .Welcome to our in-depth exploration of CNC lathe machine parts and functions. In this comprehensive guide, we will take you on a journey through the inner workings of a CNC lathe machine, providing detailed insights into the various components that make it function seamlessly. Whether you are a CNC enthusiast, a machining professional, or . CNC lathe machines are used in various industries to create precision components and parts. Setting up a CNC lathe machine involves a series of steps that need to be followed carefully to ensure optimal performance. In this article, we will discuss the basic steps to set up a CNC lathe machine and provide helpful examples along the way. . Tormach 15L Slant-PRO™ CNC Lathe | Tormach Inc. providers of personal small CNC machines, CNC tooling, and many more CNC items. It does well if you are running a few parts and don't mind fairly slow speed. I've turned 303SS and 304SS on mine with no trouble on lots of 50 or 100 small parts.

A CNC lathe is automated and controlled by computer software, allowing for higher precision and efficiency compared to a manual lathe operated by hand. CNC lathes can perform complex cuts and repetitive tasks with consistent accuracy, while manual lathes require manual adjustments and monitoring throughout the machining process.

haas cnc parts catalog

$26.99

what parts does a cnc lathe use|cnc machine parts list pdf