cnc machine installation steps The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, . Understanding the various types of sheet metal operations and their applications highlights the importance of precision metal crafting in modern manufacturing. These operations enable the .

0 · starting up dewalt cnc machine

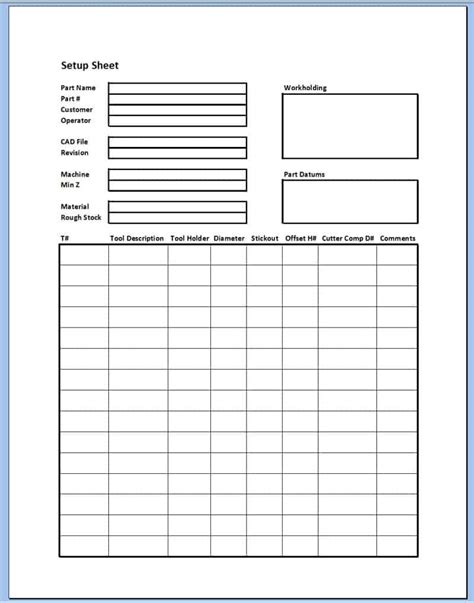

1 · cnc tool set up sheet

2 · cnc mill set up sheet

3 · cnc machines for dummies

4 · cnc machine setup sheet template

5 · cnc machine setup sheet

6 · cnc machine setup checklist

7 · cnc lathe setup sheet

Metal angles come in various materials, each offering unique characteristics that make them suitable for different applications. The most common types of metal angles are aluminum, bronze, and steel. Aluminum is known for its .

starting up dewalt cnc machine

Before installing a CNC machine, several crucial steps need to be taken to ensure a smooth and successful installation process. This section will outline the pre-installation preparations, including site selection, power and utility requirements, and compliance with safety regulations.

The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, . In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the .In this comprehensive guide, we will walk you through the step-by-step procedure for installing a CNC machine. From unpacking to final testing, this blog post will provide you with all the .

wiring a light junction box

cnc tool set up sheet

In this guide, we will walk you through step-by-step instructions, along with essential tips and tricks, to help you install your CNC machine effectively and efficiently. So, let's dive in and .

After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is . For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, . In this comprehensive guide, we will delve into the intricate details of CNC machine installation, providing you with invaluable tips and step-by-step instructions to ensure you . Here I’ll share a handy checklist you can use whenever you’re bringing a new Okuma CNC machine into your shop. Check Electrical Requirements: Find out how much .

Setting up a CNC lathe machine involves multiple steps, such as loading the CAD file, creating the toolpaths, and setting the machining parameters. It is crucial to follow a systematic approach to ensure smooth .

Before installing a CNC machine, several crucial steps need to be taken to ensure a smooth and successful installation process. This section will outline the pre-installation preparations, including site selection, power and utility requirements, and compliance with safety regulations. The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, contactor, fuse, servo motor speed, control unit socket, spindle motor speed control unit socket are loose. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the machine for any damage or wear.

In this comprehensive guide, we will walk you through the step-by-step procedure for installing a CNC machine. From unpacking to final testing, this blog post will provide you with all the information you need for a successful CNC machine installation.In this guide, we will walk you through step-by-step instructions, along with essential tips and tricks, to help you install your CNC machine effectively and efficiently. So, let's dive in and learn everything you need to know about CNC machine installation. Table of Contents: 1. Importance of Proper CNC Machine Installation. 2.After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is configured. Guides for installation, setup, and usage of Centroid CNC12 CNC controller software and compatible accessories.

wireless router in metal enclosure

For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, calibration, testing, and operator training.

In this comprehensive guide, we will delve into the intricate details of CNC machine installation, providing you with invaluable tips and step-by-step instructions to ensure you assemble and install your CNC machine tools the right way.

Here I’ll share a handy checklist you can use whenever you’re bringing a new Okuma CNC machine into your shop. Check Electrical Requirements: Find out how much current your new CNC machine will draw so you can prepare your electrical for it.

Setting up a CNC lathe machine involves multiple steps, such as loading the CAD file, creating the toolpaths, and setting the machining parameters. It is crucial to follow a systematic approach to ensure smooth operation and accurate results.Before installing a CNC machine, several crucial steps need to be taken to ensure a smooth and successful installation process. This section will outline the pre-installation preparations, including site selection, power and utility requirements, and compliance with safety regulations. The following is the correct steps for installing CNC machine. 1. Appearance Inspection Before Power On. (1) Machine tool electrical inspection: Open the machine tool electric control box, check whether the relay, contactor, fuse, servo motor speed, control unit socket, spindle motor speed control unit socket are loose. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the machine for any damage or wear.

In this comprehensive guide, we will walk you through the step-by-step procedure for installing a CNC machine. From unpacking to final testing, this blog post will provide you with all the information you need for a successful CNC machine installation.In this guide, we will walk you through step-by-step instructions, along with essential tips and tricks, to help you install your CNC machine effectively and efficiently. So, let's dive in and learn everything you need to know about CNC machine installation. Table of Contents: 1. Importance of Proper CNC Machine Installation. 2.

After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is configured. Guides for installation, setup, and usage of Centroid CNC12 CNC controller software and compatible accessories. For newcomers to CNC machinery, installation and commissioning are critical stages that lay the foundation for efficient operation. This process encompasses workshop preparation, professional machine installation, calibration, testing, and operator training. In this comprehensive guide, we will delve into the intricate details of CNC machine installation, providing you with invaluable tips and step-by-step instructions to ensure you assemble and install your CNC machine tools the right way.

Here I’ll share a handy checklist you can use whenever you’re bringing a new Okuma CNC machine into your shop. Check Electrical Requirements: Find out how much current your new CNC machine will draw so you can prepare your electrical for it.

cnc mill set up sheet

Sheet Metal Ducts Material – Typically made out of galvanized steel or aluminum, they offer a longer-lasting, sturdier solution to flexible or fabric ductwork. Popularity – Sheet metal vents .

cnc machine installation steps|cnc machine setup sheet