sheet metal bend radius rule of thumb Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the material that you’re forming. In other words, if . What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or stainless steel metal sheets are too thin, we recommend that you use the TIG technique.

0 · sheet metal minimum bend length

1 · sheet metal bending design guidelines

2 · sheet metal bending chart

3 · sheet metal bend relief guidelines

4 · sheet metal bend radius standard

5 · sheet metal bend radius guide

6 · bending steel plate minimum radius

7 · bend radius sheet metal chart

Set the Smoker Box right on top of your cooking grates to transform any gas or charcoal barbecue into a smoke cooker that will give your meats, veggies, nuts and cheeses the mouthwatering .

sheet metal minimum bend length

Rule of thumb: To prevent parts from fracturing or distorting, make sure to keep the inside bend radius at least equal to the sheet’s thickness.Here’s a good rule of thumb for most materials: The inside bend radius should be equal to the thickness of the material that you’re forming. In other words, if . A Rule of Thumb in Metal Bending. There’s a rule of thumb to determine a steel’s minimum bend radius, and this generally works for aluminum too: Divide 50 by the material’s tensile reduction percentage as specified by . Choose the right bend radius for the material and thickness of the sheet metal. Use proper bending techniques, such as air bending or bottom bending, depending on the desired bend angle. Consider the tooling .

To ensure successful bending, it is recommended to place holes away from bends at a distance of at least 2.5 times the material’s thickness (T) plus the bend radius (R). For slots, it is recommended to position it at least 4 times the .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for .

best way to clean dust from cnc machine

Question: My co-workers and I have been reading your columns to help us understand what tooling our shop will need to avoid overstressing our materials with small dies. We air bend our 0.125-inch-thick 5052-H32 .Use this sheet metal bending design guidelines when designing your parts for manufacturing. 1. Bend Relief 2. . suitable for designs where the bend radius is not too tight, . Therefore, a good rule of thumb is to leave a minimum space . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. . While sheet metal gauges run from 0.005 to 0.249 inch .The genera Sheet Metal Design rules of thumb. In sheet metal design, the “Rule of Sixes” serves as a pivotal guideline, particularly for bending operations. This rule advocates for a minimum bend radius, bend relief width, and bend distance, each being six times the material thickness.

Search for jobs related to Sheet metal bend radius rule of thumb or hire on the world's largest freelancing marketplace with 24m+ jobs. It's free to sign up and bid on jobs. An overview of bend radius for sheet metal, including types, materials, tools, and important design considerations is provided in this article. +1(213) 398 9420 . Mild steel: A common rule of thumb is that the minimum inside bend radius should equal the material thickness. If the material is 0.125 inches thick, the minimum inside bend radius .

Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips. . Rule Of Thumb: 2.5* Material Thickness + Bend Radius. . Rule Of Thumb: Never design a hole .A common rule of thumb in sheet metal design is the "Rule of Sixes," which states that for bending operations: 1. Use a minimum bend radius of six times the material thickness. 2. Use a minimum bend relief width of six times the material thickness. 3. Maintain a minimum bend distance of six times the material thickness between bends.Sheet metal parts are used all over and are great for enclosures and housings. 1 vin mostbet casino pin up casino lucky . so does the bend radius produced by the punch. A general rule of thumb is to apply a bend radius equal to the material thickness, for a 2mm thick sheet this would mean applying 2mm bend radii. It is possible to apply, for .The sheet metal thickness is 0.08", bend radius is 0.05". Reply reply . I've kept the minimum bend radius of 1x sheet thickness as rule of thumb. Would it possible for the fabricator to test making those pieces so, that the plate grain direction is changed, as that will change the bend behavior a bit? .

The 8 rule is a rule of thumb applicable to the V-shape die opening, which means that the V-shape die opening should be 8 times the material thickness. . There is no perfect sheet metal bend radius formula, but within the specified bending force range, the inner radius roughly equal to the plate thickness can be calculated. Of course, the .

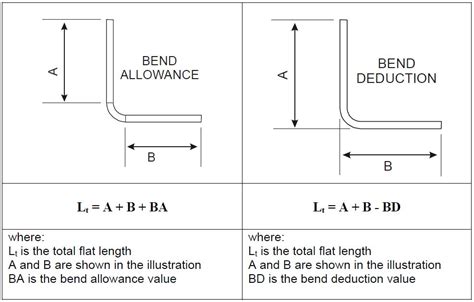

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Bend Radius. Sheet metal bend brakes are used to bend material into the parts desired geometry. Bends that are in the same plane need to be designed in the same direction to avoid part re orientation, to save both money and time. . Rule of thumb It is recommended to use the same radii across all bends, and flange length must be at least 4 .I work at a sheet metal shop and the thumb rule for minimum bend radius is sheet thickness. For tolerances 99% of the times its ISO 2768 - m. The correction factor should be determined by the manufacturer. They usually have tables for their specific machines and stock. The minimal diameter for holes we can laser is ~ sheet thickness.It is dependent on bend radius and material thickness. Also as far as drawing that part up draw a single line profile sketch of the shape you want, Hit the sheet metal base flange tab, set the length of the edge. . but if you don't know what size .

sheet metal bending design guidelines

Laser cut sheet metal is a popular material in many industries due to its durability, strength, and versatility. At SendCutSend, we stock multiple high-quality materials and offer CNC bending services so your project is limited .With sheet metal the rule of thumb is thickness/2 for minimum bend radius. I.e. if you're working with .062" stock, don't drop under .031" bend radius. Acrylic you have to heat up to deform, and when you do that you're typically pulling it over a form with a vacuum.

90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii. The minimum permissible radii will also vary with the design and condition of the tooling. The 20 percent rule percentages for other materials can be estimated by comparing the tensile strengths of the material with any sheet metal supplier's material characteristics sheet. Rule of Thumb In the old days a rule of thumb for selecting a die width was that the die width should be six to 12 times that of the material thickness. I'm interested in bending a piece of sheet metal to a specific radius. In one case the sheet will be formed from 6092 aluminum. . but as a rule of thumb anything higher than 5054 is not intended to bend. . The max-minimum inside radius sheet metal (unhardened) can be formed on the brake press is .63 x material thickness. It cannot be formed .Cari pekerjaan yang berkaitan dengan Sheet metal bend radius rule of thumb atau upah di pasaran bebas terbesar di dunia dengan pekerjaan 23 m +. Ia percuma untuk mendaftar dan bida pada pekerjaan.

The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness.

The rule of thumb is that the minimum bend radius should be equal to the thickness of the metal, although this can vary depending on the malleability of the specific metal. . Understanding what the bend radius in sheet metal is before working on it is a crucial consideration that influences the final product’s quality and integrity. The .

K-Factor is Linear. Assuming linear increase/decrease of bend allowance with bend angle. Apply same K to all bends. A bigger bend radius tool will have different K than a smaller one. Need to use bend table in this case. Bend Table is test result on machine. The old "rule of thumb". Allow different bend allowance on different bend angle, radius. One rule of thumb to avoid a sharp bend is to use a punch radius larger than 63 percent of the material thickness. For a more precise estimate, multiply this amount by a factor that describes the strength of the material in relation to cold-rolled steel. Contact the Metal Bending Experts at APX York Sheet Metal

When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features, such as countersinks are doable, but counterbores and other machined features are difficult to produce as they require post-machining. Bends Sheet metal brakes are used to bend material into a part’s desired geometry.

sheet metal bending chart

sheet metal bend relief guidelines

In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for welding sheet metal so if you want to read it hop in.

sheet metal bend radius rule of thumb|bending steel plate minimum radius