sheet metal bending tolerance standard The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges .

KitchenCraft Living Nostalgia Milk Bottle Holder Doorstep, Milk Crate, Wire Metal with Wooden Handle, 29 x 20 x 13cm, Grey

0 · standard sheet metal tolerances chart

1 · sheet metal tolerances chart

2 · sheet metal thickness tolerance chart

3 · sheet metal bend tolerance chart

4 · open tolerance chart in mm

5 · maximum thickness sheet metal bending

6 · is 7215 pdf latest

7 · is 7215 pdf free download

These shelf brackets are made of strong, solid steel, and the max load to 110 .

Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the holdable tolerances could be for usual shop floor operations.

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce .

a The thickness tolerances for sheet in coil form are the same as for sheet supplied in cut lengths but, in cases where welds are present, the tolerances shall be double those given over a length of 15 m in the vicinity of the weld. . Table 7 — Standard flatness tolerances for cut lengths Dimensions and tolerances in millimetres Specified .

The manufacturing process used for specific features in sheet metal fabrication impacts tolerances. While features located on the same surface can achieve standard tolerances of +/- 0.005", formed features like flanges .This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Search Now. . Bend angles have a standard tolerance of ± 1°. Bend length .Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Bending can improve a part’s structural integrity by increasing part stiffness, redistributing stress within a part, and help .

There are astm standards for sheet metal manufacturers that define the mechanical and physical properties limits for product coming from a rolling mill - where your sheet metal is coming from. From Working in a sheet metal penny for past 10 years I'd say . 5mm over 200mm flatness will be difficulty to achieve unless you have a specially agreed . 0.3.1 In this standard only groups B and C are covered. The tolerances for the fabrication of steel railway bridges and allied structures which fall into Group A will be covered in a separate standard. 0.4 This standard keeps in view the practice being followed in .

EF-001 Recommended Default Sheet Metal Tolerances Rev A Recommended Default Sheet Metal Tolerances Default Tolerances (Millimeters) DIM Tolerance Description A ± 0.13 Sheared Edge to Hole B ± 0.13 2 Holes on One Surface C ± 0.25 Formed Edge to Hole D* ± 0.76 Holes Across 2 Bends E* ± 0.76 Holes Across 4 Bends F ± 0.25 Sheared Edge to Bend .

This is a common issue due to the large sheet metal bending tolerances, particularly when the sheet metal has multiple bends. Features Tolerance/mm; One bend: 0.15: Two bend: 0.25: Three bend: 0.36: Four bend: 0.44: Five bend: 0.51: Six bend: 0.59: The punch is brought down sharply using a hydraulic ram, to bend the sheet metal part in the desired shape. Bending of a sheet metal part . Dowel Pin Tolerance and Fit Standards. Factorem’s mission is to provide a seamless access to fast, high quality custom manufacturing in Southeast Asia. Mar 28, 2021.International Standards for Sheet Metal Dimensions. Shengen adheres to the international standards of tolerances in sheet metal fabrication. These standards are a common framework and language that ensures the parts and assemblies we produce are compatible worldwide. We follow several critical criteria, including: Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. . Bend Angles: The standard tolerance for bend angles is ± 0.5°, ensuring precision while allowing for minimal variance. Bend Length: Tolerances for bend length are generally ±0.20 mm .

Sheet Metal Design Guidelines for Fabrication: Engineer’s Handbook; The Ultimate Guide to Metal Blanking: Everything You Need to Know; Metal Bending: The Ultimate Guide; The Ultimate Guide to CNC Turret Punch Press; Press Brake FAQs: Get Your Ultimate Answers; 28 Sheet Metal Bending Problems and Solutions

standard sheet metal tolerances chart

Learn how to find bend angle tolerance specifications for each material. Keep in mind that metal and plastic material have different tolerance considerations. Learn more about bending plastic. Dimensional tolerances for single bends. At SendCutSend, simple, single flange parts will have a +/- 0.015” dimensional tolerance, bend to edge.

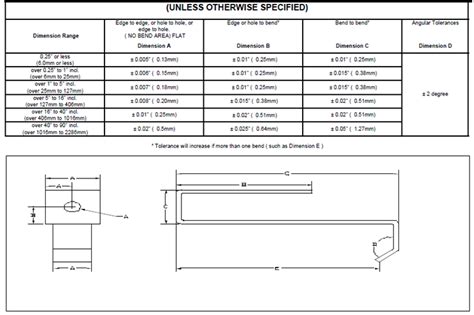

Industry Standards for Sheet Metal Tolerances. Different international guidelines standards are set for sheet metal tolerances. These guidelines and standards guarantee quality and consistency across different manufacturers and industries. ISO 2768. ISO 2768 is an important standard for general tolerances in sheet metal fabrication.Edge to edge, or hole to hole, or Edge or hole to bend* Bend to bend* Angular Tolerances edge to hole. ( NO BEND AREA) FLAT 0.25" or less (6.0mm or less) over 0.25" to 1" incl. (over 6mm to 25mm) over 1" to 5" incl. (over 25mm to 127mm) over 5" to 16" incl. (over 127mm to 406mm) over 16" to 40" incl. (over 406mm to 1016mm) over 40" to 90" incl . ISO Standards: ISO 2768 is a prevalent standard in sheet metal fabrication, covering tolerance requirements for multiple industries. This standard helps in balancing costs and processing capabilities. . Sheet metal .

Sheet metal Tolerance Standrards, welding Tolerance Standards, General Tolerance Standards, IS 2102 Tolerance details, V groove pulley material

It applies to the dimensions of parts that are produced by metal removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see IS0 60621) for castings. Tolerances in bending involve more than just the angle tolerances shown on the print. Materials also have tolerances, both in thickness and yield strength. . Many press brake manufacturers use databases calculated based on a given press brake design and standard sheet metal characteristics as dictated by the mill’s ASTM requirements and .Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles. Other standard bend radii available, some of which will add additional cost to your part, include: 0.9mm – 1 .Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . these are standard tolerances. In many cases, we can tighten these up, but there's usually a cost. So, if you run into a situation where you need tighter tolerances to make your project work - please let us know.

For part sizes without marked tolerance ranges, this standard should be followed. Please note that all tolerance limits are given in mm. Part 1: General Tolerances ISO 2768-1. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f – fine, m – medium, c – coarse, v – very coarse).The parts quoted were two bend sheet metal channels with holes in the top for slugs to weld to. Two parts needed to align together but overall channel dimensions has a bit of forgiveness in fit. . Use decimal dimensions Have a reasonable standard tolerance defined in the title block. I think our default is: .X = +/- .125 .XX = +/- .040 .XXX .4. Regular perpendicularity tolerance JIS B 0419 −1991− Units: mm 5. Regular straightness and flatness tolerance JIS B 0419 −1991− Units: mm 6. Regular symmetry tolerance Units: mm 3. Angle tolerance Units: mm [TECHNICAL DATA] STANDARD MACHINING TOLERANCES Excerpts from JIS B 0405 1991) JIS B 0419 (1991) ±0.05 ±0.1 ±0.15 ±0.2 .

Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. . Minimum Bend Radii: The minimum bend radii data contained within the given charts are measured to the inside of the bend. The bend radii listed are standard minimum for manufacturing for aerospace and space applications. Commercial sheet .GENERAL TOLERANCES FOR FORM AND POSITION (DIN ISO 2768 T2) STRAIGHTNESS AND FLATNESS Ranges in nominal Tolerance class lengths in mm H K L up to 10 0.02 0.05 0.1 over 10 up to 30 0.05 0.1 0.2 over 30 up to 100 0.1 0.2 0.4 over 100 up to 300 0.2 0.4 0.8 over 300 up to 1000 0.3 0.6 1.2 over 1000 up to 3000 0.4 0.8 1.6Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. Transform your team's workflow with Protocase Designer Enterprise, the game-changing design tool for collaboration! . Standard Tolerances For Copper. Usually, choosing material thickness is one of the first .

sheet metal tolerances chart

There are two materials that are commonly used for racking systems: wood and metal. Here are some considerations to make when deciding between the two.

sheet metal bending tolerance standard|is 7215 pdf latest