sheet metal bending radius calculation The sheet metal bending radius is a critical value in sheet metal drawing that can be . Allow us to make your bathroom or kitchen dream cabinet into a reality. At United Wholesale, we are leaders in the wholesale cabinet industry. We work with six different, expert cabinet manufacturers. Quality, value and style are the earmarks of our service and craftsmanship.

0 · sheet metal folding calculator

1 · sheet metal bending calculator free

2 · sheet metal bending calculation excel

3 · sheet metal bending angle chart

4 · sheet metal bending angle calculator

5 · sheet metal bend deduction chart

6 · online sheet metal bending calculator

7 · calculate sheet metal flat pattern

Our metal building home packages allow you – whether you’re a DIYer or you hire a contractor – to quickly and easily build a prefab home that goes up faster and costs less per square foot than traditional wood-based construction.

Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations.The sheet metal bending radius is a critical value in sheet metal drawing that can be .Learn how to accurately calculate bend allowance with our easy-to-understand .

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .

Use SendCutSend’s bending calculator to input your desired material .The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the .Press Brake bend radius, bend deduction, bend allowance, and K factor are important parameters in sheet metal processing.. Sheet metal processing is a comprehensive cold-working process for sheet metal materials (usually below .

How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): Bend radius (in): Bend angle (°): K-factor: Setback (in): Bend allowance (in): Bend deduction (in): Bending Springback Calculator.Sheet Metal Bending Parameters Calculator Here you can insert the characteristics of the sheet metal to be bent (internal radius, V-die opening and minimum flange) . The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel. Bending Force Calculation Our press brake bending calculator can help you based on the [.]Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw size . Bending Radius (R) is inside radius at which bending of the plate take place. bending radius is also important parameter too small bending radius is causes to developed crack on the plate so choosing bending radius is also .

Using CAD Software for Bend Radius Calculations. . The sheet metal bend radius refers to the inner radius of the bent sheet metal part. This is an essential factor during sheet metal fabrication because it impacts a part’s strength, design, and quality. Bend radii are most often expressed in specific relation to the thickness of the .

sheet metal folding calculator

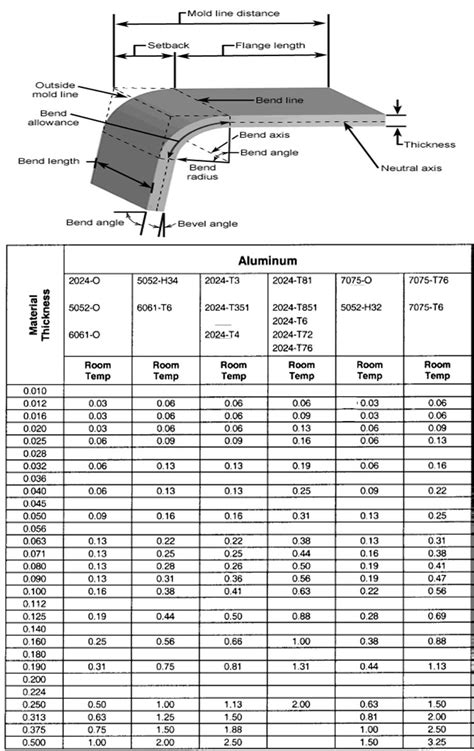

How to Calculate Bend Radius Understanding Bend Radius. The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. To enhance the readers’ understanding of basic concepts in sheet metal design calculation, the following points will be summarized and explained:. The definitions of the two bending algorithms: bend allowance and bend deduction, and their connection to the actual sheet metal geometry. The relationship between bend deduction and bend allowance, and how .

stainless steel 3 gauge enclosure

The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal. However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table.K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the inside bending surface is compressed, whereas the outer surface is stretched.The TRUMPF BendGuide app performs bending calculations more easily and clearly than ever before. . Inner radius; Sheet thickness conversion; Tool weight calculation; Sheet metal weight calculation; Download the app In the "More" menu item, you can convert the units of measurement from metric to the Anglo-American system. .

Home; Engineering; Mechanical; Sheet metal bend allowance calculator - formula & step by step calculation to find the flat pattern length when a bend is dimensioned either from the centre of radius or a tangent point of radius or the outside tangent point of the radius on an acute angle bend. BA = [A x (π/180) (r + (K x T))]. The bend angle A in degrees, inside bend radius R in m, .The variables in this formula include: S: Sheet thickness; r: Inner radius during bending; K: Width of the horizontal projection of the bending deformation zone; From the derivation process, it is essential to meet two additional conditions when using formulas (2) or (3) to calculate bending force: the width-to-thickness ratio (V/S) must equal 9, and the radius-to-width ratio must equal . In sheet metal fabrication, curving sheets according to a specific bend radius is one of the most common operations used to create flanges, curls, seams etc.Moreover, bending imparts much strength to the sheet metal .

sheet metal bending calculator free

Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu . Bend . Question: My co-workers and I have been reading your columns to help us understand what tooling our shop will need to avoid overstressing our materials with small dies. We air bend our 0.125-inch-thick 5052-H32 .

The final bend radius and bend angle can be approximated from the sheet thickness, K-factor, material yield strength and modulus of elasticity, and the initial bend angle and bend radius. The final bend radius will be greater than initially formed and the final bend angle will be smaller. The springback factor, Ks, will show the ratio of the . In bottoming or coining, use the punch nose radius as the inside bend radius in your bend deduction calculations. But if you are air forming, the inside bend radius is produced as a percentage of the die opening. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of the Fabricators & Manufacturers .

K-factor in sheet metal is a constant used to calculate sheet metal bend allowance, bend deduction, Flat length and Neutral axis position. . Mathematically outside setback is equal to the product of the sum of sheet thickness & inside bend radius and tangent of the half of bending angle. Outside Setback ( OSSB ) = Tan (A / 2) × (T + R)

Quick calculation of the angle of a radius bend However, many consecutive bends can cause an accumulation of errors, both in terms of the final angle and the radius of the bend. For this reason, it is important to rely on a press brake with a very precise backgauge and .Bending rule and rulers to calculate the tonnage of "U" profiles, "Z" profiles, flattened profiles and offset Z profiles. By using this site you agree to the use of cookies for analysis and personalized content.

We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material. Ease of Manufacturing: Bend Deduction simplifies the calculation process for the flat pattern layout, making it easier for fabricators to cut and bend the sheet metal accurately. How Bend Deduction is Calculated. Bend Deduction depends on the bend angle (A), the material thickness (T), the inside bend radius (R), and the K-factor (K).

Sheet metal bending calculator. Our online calculator allows you to determine sheet metal bending parameters within seconds accurately. Enter your project data and instantly get tonnage, inner radius and minimum edge. . Bending radius. The inner radius of the bent part depends substantially on the die opening and, to a lesser extent, the .

sheet metal bending calculation excel

BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Calculates the K-Factor given the bend angle, material thickness, radius and bend deduction. Calculator 5: Calculates Tonnage required to bend given the bending method, material .

stainless steel bbq cabinets melbourne

stainless steel bar cabinet pulls

We offer instant online quotes, payment and ordering for high-quality, high-precision, custom metal parts – straight from our factory. Get exact pricing in 30 seconds! Upload your 3D drawings to our secure platform in STP, STEP, or .

sheet metal bending radius calculation|sheet metal folding calculator