how to bend sheet metal corners Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Old work electrical boxes have plastic tabs that tighten onto drywall after walls/ceilings are installed. New work electrical boxes have nails that are hammered into wooden joists/studs when these are exposed during new builds/renovations.

0 · sheet metal bending dies

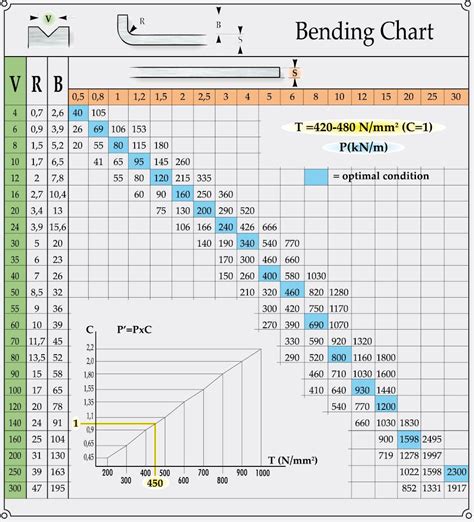

1 · sheet metal bending chart

2 · sheet metal bending by hand

3 · how to bend metal professionally

4 · folding sheet metal at home

5 · bending operation in sheet metal

6 · bending 16 gauge sheet metal

7 · bend sheet metal without brake

Below is a list of NEMA enclosure types; these types are further defined in NEMA 250- Enclosures for Electrical Equipment. Each type specifies characteristics of an enclosure, but not, for example, a specific enclosure size.

sheet metal bending dies

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet . The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on .You can add a corner relief to a single sheet metal body. Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. .

How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.

If you bend to a sharp inside corner with sheet metal, you’ll be adding a ton of internal stresses. Even on malleable materials, you can end up cracking the metal at the bend, or weakening it to the point where it’ll break with minimal force.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. SHEET METAL Training with TOBY: www.TooTallToby.com/training More SOLIDWORKS SHEET METAL videos: https://youtube.com/playlist?list=PLzMIhOgu1Y5deswXMjjl9J. A bend relief is nothing more than two small incisions cut into a piece of sheet metal to free the metal between the two. It separates the material you want to be able to fold from the rest of the part. You only need it when .

What can you expect from a sheet metal bend corner? How will it look and how can you adjust them? Today I will give you some examples of bend corners and how they appear in the flat pattern and the folded model. I will .

I made a sheet metal part in V5R3 by using Extrusion, Wall on Edge, etc.After that I made the Automatic bend and I am able to nicely Unfold the part. To round the corners I have to start the Part design Workbench and use the Fillet command. It is OK but in unfolded view they'll be never visible. The sheet metal bodies can be split up to individual sheet metal components and they can be joined to other components. However, only the moldings on the left and right side of the box can have a joint origin point at .

Solid edge Tutorial Feature 2 - bend Corner in solid edge.In this Video will show how to use bend corner on drawingim just a hobbyist and need to bend 1/16 sheet metal 4 times as seen below. all dimensions are in inches. going from left to right, the bends are 1, up 1.7, over 1.7, down 1.7, and over 1. . Just clamp the metal onto the wood and use the mallet to bang the metal around the corners of the wood. The wood basically acts as a bending jig. Reply .Break corner/Corner trim is a quick way to add a chamfer or fillet to all the sharp corners. You can select a face and it will automatically apply to all the corners or you can select corners one by one. Corner relief is for controlling if/how material is removed from the base flange where two or three corners come together. Learn how to make rounded bends with a sheet metal brake in this informative video tutorial.

make all the corner cutouts. score the end flap [4] and [5] creases with a sharp knife. bend down the end flaps, [4] and [5] using the brake. bend the end flaps [4] and [5] back up again using the brake so the cutout is flat again, this will leave a strong crease. Do a Z-bend on the brake to make the bends for [1], [2] and [3] #MdDesignAcademy #Creo_Tutorial #Creo_Tutorial_For_BeginnersIn this video tutorial we will learn about following under Sheet metals Module:~how Conversions a.

sheet metal bending chart

Plasma cutting bend relief cuts for hand bending sheet metal. I'm an absolute 100% newbie to CNC plasma cutting, CAD, and solidworks. I tried Freecad, and Fusion 360, but Solidworks feels like it has just "clicked" for me, particularly with 3D parts, which is what most of my needs are. . There is an auto corner relief tool, but it will only . 2 Bend Transition. Round – A corner relief defined by a circular cutout in the flat at left. The cutout has a center placed on the intersection of the bend lines. Below are two views of the folded corner. Square – A relief shape with a square cutout and centered on the bend line intersection of the two bend lines.My workflow to create an overlapping corner in Fusion 360 You can model the corner with the Cut across Bend feature: select one of the faces of ContourFlange1 to create a sketch and "flat project" the faces adjacent to the corner. Then model your relief as sketch profile and use Cut across Bend to cut it (pictures and R11 part are attached) Lucia Casu Inventor Part Modeling

In this quick tip, we will cover some best practices with sheet metal in Fusion 360. Rule 1, flat patterns, and flange options are just a few of the tips cov.

Finally, make sure the sheet is filed down smoothly, because otherwise you may get cracks in the metal. Place Forms and Sheet in Vise: Your form blocks should have the exact shape for bending your metal angle. When you clamp the sheet metal into the vise’s grip, make sure the bend lines on your blocks and sheet match up. Onshape uses a unique approach to bent and flattened states of a sheet metal component that allow you to modify the design in both states.In this Tech Tip, f.The closed corner feature adds material between sheet metal features, and includes the following capabilities: Close multiple corners simultaneously by selecting the faces for all of the corners that you want to close. Close non . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Could anyone help please, I'm using Inventor 2008 Pro in the sheet metal format, and having a slight problem with corners!! The guys in the workshop are telling me that when they bend up an enclosure the edges of the flanges are always corner to corner. I've been trying to achieve this by creatin. Simple Techniques For Bend Metal Sheet Easily / Diy Sheet Metal Projects Hi Friends. NAMASTE. Welcome To The Fab2ku Family.Guy's..Let's make a .

Tech Tip: How to Modify Sheet Metal Corners in Onshape. Jenny E. Johnson. READ TIME: 1:19 . When you convert sheet metal components from legacy systems you often need different sheet metal bend geometry. Onshape uses a unique approach to bent and flattened states of a component that allows you to modify the design in both states.Sheet metal bend reliefs Does anyone know how to close the bend reliefs fully? I've tried changing every setting in the sheet metal rules but always end up with big gaps at every bend instead of tight corners. I have pictures of my fusion project and pictures of how the machine shop does it. . sheet metal corners question upvote . Although condensate pans are fairly simple to fabricate, you will need to have basic knowledge of cutting and bending sheet metal, as well as soldering or welding to make the corners water-tight. Step 1. Measure the size condensate pan you need and add 2 inches to that measurement. For example, if you need a 30 by 30 inch condensate pan .

In SOLIDWORKS 2017, you can create corner reliefs where three bends meet at one common point. The corner relief is applied at the common intersection point o.

That isn't an extrusion. That's a piece of brake metal which is formed or rolled from sheet metal. It was broken either by the manufacturer or by the sheet metal shop. An extrusion is a piece of metal (typically aluminum) that is extruded from a die or mold while molten.

SolidWorks Sheet Metal Tutorial for Beginner - 2 | Closed Corner, Welded Corner, Break Corner, Corner Trim, Forming Tool. This tutorial shows how to create f. To avoid the need to edit the corners every time - change the settings for the corner seam gap to a smaller value. As it is shown on the attached image. And save the settings to your sheet metal template. Cheers, Igor. This video show how to use SolidWorks to add a "Cut" feature through a folded sheet metal corner creating a miter that can still be unfolded.Focus is on the .

One of the coating weight designation systems in this standard uses descriptors such as G60, G90, etc. The “G” means the coating is galvanize (zinc), and the numbers refer to the weight .

how to bend sheet metal corners|folding sheet metal at home