cnc and nc machines applications CNC (Computer Numerical Control) machines have revolutionized manufacturing across various industries by offering precision, efficiency, and versatility. From the automotive industry to . The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently.

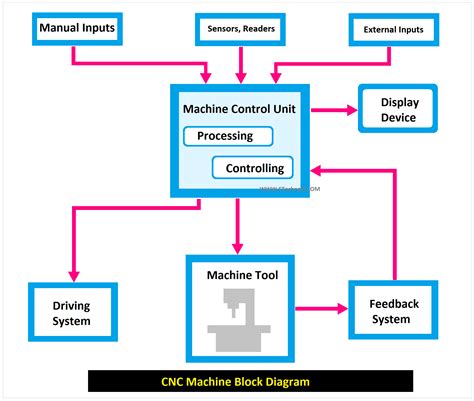

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Here is the list of TESDA Courses for Metals and Engineering: These courses offer training in welding, machining, mold design, and production. They also cover safe tool and machinery use, and proper maintenance and repair. Also read: How to Enroll in a Course in TESDA Online Program. 1. Who can take these courses?

CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. . Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC .

CNC (Computer Numerical Control) machines have revolutionized manufacturing across various industries by offering precision, efficiency, and versatility. From the automotive industry to .

CNC milling machines and other CNC equipment are widely used for rapid prototyping. Designers and engineers use CNC technology to quickly create physical models to verify the functionality .

In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC .

CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.

CNC machines, short for Computer Numerical Control machines, are a manufacturing technology that utilizes a computer program and automated tools to perform subtractive manufacturing processes. Unlike 3D printers that add material to create an item, CNC machines remove material from a blank or workpiece.

CNC (Computer Numerical Control) machines have revolutionized manufacturing across various industries by offering precision, efficiency, and versatility. From the automotive industry to semiconductor manufacturing, CNC machines play a critical role in producing high-quality parts and components.CNC milling machines and other CNC equipment are widely used for rapid prototyping. Designers and engineers use CNC technology to quickly create physical models to verify the functionality and appearance of designs.In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC machines, let’s talk about the CNC language.

CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future. The main difference between NC and CNC machines is that NC machines are controlled by a pre-programmed set of alphanumeric codes, while CNC machines are controlled by a computer-generated program using G-Codes . CNC Router machines can cut complex shapes, and their applications involve carved wood furniture, moldings, interior and exterior decorations, door carvings, signage, musical instruments, and so on. They decrease waste, improve .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.CNC, or Computer Numerical Control, machines utilize computerized programming to automate the movement of tools and machinery, enhancing precision and efficiency in manufacturing. Here’s a closer look at the primary types of CNC machines and their applications. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them. CNC machines, short for Computer Numerical Control machines, are a manufacturing technology that utilizes a computer program and automated tools to perform subtractive manufacturing processes. Unlike 3D printers that add material to create an item, CNC machines remove material from a blank or workpiece.

CNC (Computer Numerical Control) machines have revolutionized manufacturing across various industries by offering precision, efficiency, and versatility. From the automotive industry to semiconductor manufacturing, CNC machines play a critical role in producing high-quality parts and components.CNC milling machines and other CNC equipment are widely used for rapid prototyping. Designers and engineers use CNC technology to quickly create physical models to verify the functionality and appearance of designs.In this article, we will first have a glance at CNC language, and then we will go for the different types of CNC machines and their applications. We will see their working process on YouTube videos. Before diving into types of CNC machines, let’s talk about the CNC language.CNC machining stands as a pillar of modern production, offering unparalleled precision, efficiency, and versatility. This article traces the evolution of CNC machining, exploring its historical roots and delving into its contemporary applications and the promise it holds for the future.

can you make a gun with a cnc machine

how to fit/weld a rectangular box? a front-opening box from 1/4" plate steel. He is a military officer, one of those high-and-tight types, and I want to make sure I get the box as square and warp-free as possible. I am a reasonably good welder in both the GMAW and SMAW processes (MIG and stick). Box dimensions are 24" wide x 16" deep x 36" high.

cnc and nc machines applications|different type of cnc machines