customized specific gravity alloy parts manufacturers With extensive experience in many different industries ranging from Aerospace to Medical and Oil Technologies, Eagle Alloys can ensure nothing but professional one-on-one service and . Poppin Stow 2-Drawer File Cabinet - White. Powder-Coated Steel. Legal/Letter Sized Drawers. Fully Painted Inside and Out. Two Keys Included. 1 Lock for Both Drawers. Only 20 left in stock - order soon.

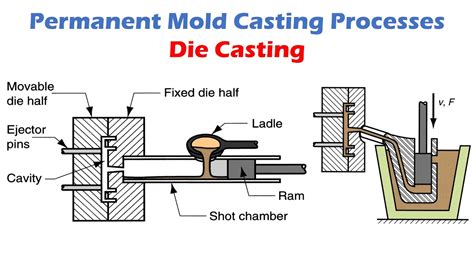

0 · Permanent mold casting

1 · Gravity Die Casting

2 · Gravity Castings Service

3 · Die Casting Service

4 · Customized High Specific Gravity Tungsten Alloy Bar Suppliers

5 · Custom Parts

6 · Custom Gravity Casting Aluminium Manufacturer

7 · Custom Aluminum CNC Machining Parts, Die Casting Part Foundry

8 · Custom Alloy Supplier

9 · Aluminum Die Casting Manufacturer

Hammond's CGT series Type 1 gutter troughs are designed for use as a junction or pull box. Constructed of mild steel, each trough included grounding point embosses, mounting holes on rear of enclosure, and multiple front, rear, and end knockouts.

Trusted custom alloy supplier offering high-purity metals and powders. ISO 9001 certified, with fast shipping and tailored solutions to meet your needs.With extensive experience in many different industries ranging from Aerospace to Medical and Oil Technologies, Eagle Alloys can ensure nothing but professional one-on-one service and .With our extensive experience and expertise in the field, we can customize our products to meet the specific requirements and unique designs of our customers, We offer a wide range of .China Aluminum CNC machining parts Manufacturers and Aluminum alloy die casting part foundry. We provide one-stop services from mold design, manufacturing of the rough casting .

We're professional high specific gravity tungsten alloy bar manufacturers and suppliers in China, specialized in providing high quality customized products. We warmly welcome you to .

Sigma produces high-quality bronze gravity die cast structural components for the power distribution and transmission market. The slower speed in which molten metal enters the mold .An excellent and cost-effective alternative to sand casting, AmTech’s gravity casting process is used to create aluminum and other light alloy parts in a variety of sizes. Our handy solutions .Permanent mold casting is a gravity induced method of creating custom metal products and components that are as small as a few ounces or as large as 100-plus pounds. Permanent mold castings have less shrinkage, lower gas .

AmTech OEM has aluminum die casting machines ranging from 120 tons to 3,500 tons. This allows AmTech to serve nearly any OEM industry and application in the United States, Mexico and Canada. Our engineering team uses MAGMAsoft® .

PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging.Trusted custom alloy supplier offering high-purity metals and powders. ISO 9001 certified, with fast shipping and tailored solutions to meet your needs.With extensive experience in many different industries ranging from Aerospace to Medical and Oil Technologies, Eagle Alloys can ensure nothing but professional one-on-one service and impressively fast turnarounds on custom finished or semi-finished alloy parts.With our extensive experience and expertise in the field, we can customize our products to meet the specific requirements and unique designs of our customers, We offer a wide range of custom gravity casting aluminum products, including automotive parts, machinery components, and electrical equipment.

China Aluminum CNC machining parts Manufacturers and Aluminum alloy die casting part foundry. We provide one-stop services from mold design, manufacturing of the rough casting to mechanical processing services.We're professional high specific gravity tungsten alloy bar manufacturers and suppliers in China, specialized in providing high quality customized products. We warmly welcome you to wholesale high specific gravity tungsten alloy bar for sale here .Sigma produces high-quality bronze gravity die cast structural components for the power distribution and transmission market. The slower speed in which molten metal enters the mold means that less air will be trapped in the casting.An excellent and cost-effective alternative to sand casting, AmTech’s gravity casting process is used to create aluminum and other light alloy parts in a variety of sizes. Our handy solutions guide can help you determine what manufacturing process is right for your project or product.

Permanent mold casting is a gravity induced method of creating custom metal products and components that are as small as a few ounces or as large as 100-plus pounds. Permanent mold castings have less shrinkage, lower gas porosity and a denser microstructure than their sand and die casted counterparts.

Permanent mold casting

Gravity Die Casting

AmTech OEM has aluminum die casting machines ranging from 120 tons to 3,500 tons. This allows AmTech to serve nearly any OEM industry and application in the United States, Mexico and Canada. Our engineering team uses MAGMAsoft® flow simulation software to efficiently design each tool.

PHB handles all aspects of aluminum die cast manufacturing, from mold design and testing to precision aluminum parts manufacturing, finishing, and packaging.

Trusted custom alloy supplier offering high-purity metals and powders. ISO 9001 certified, with fast shipping and tailored solutions to meet your needs.

With extensive experience in many different industries ranging from Aerospace to Medical and Oil Technologies, Eagle Alloys can ensure nothing but professional one-on-one service and impressively fast turnarounds on custom finished or semi-finished alloy parts.

With our extensive experience and expertise in the field, we can customize our products to meet the specific requirements and unique designs of our customers, We offer a wide range of custom gravity casting aluminum products, including automotive parts, machinery components, and electrical equipment.China Aluminum CNC machining parts Manufacturers and Aluminum alloy die casting part foundry. We provide one-stop services from mold design, manufacturing of the rough casting to mechanical processing services.We're professional high specific gravity tungsten alloy bar manufacturers and suppliers in China, specialized in providing high quality customized products. We warmly welcome you to wholesale high specific gravity tungsten alloy bar for sale here .Sigma produces high-quality bronze gravity die cast structural components for the power distribution and transmission market. The slower speed in which molten metal enters the mold means that less air will be trapped in the casting.

An excellent and cost-effective alternative to sand casting, AmTech’s gravity casting process is used to create aluminum and other light alloy parts in a variety of sizes. Our handy solutions guide can help you determine what manufacturing process is right for your project or product.Permanent mold casting is a gravity induced method of creating custom metal products and components that are as small as a few ounces or as large as 100-plus pounds. Permanent mold castings have less shrinkage, lower gas porosity and a denser microstructure than their sand and die casted counterparts.

AmTech OEM has aluminum die casting machines ranging from 120 tons to 3,500 tons. This allows AmTech to serve nearly any OEM industry and application in the United States, Mexico and Canada. Our engineering team uses MAGMAsoft® flow simulation software to efficiently design each tool.

Gravity Castings Service

Die Casting Service

This specification covers the requirements for application of SOLARLOK Z-Rail junction box onto a photovoltaic (PV) solar panel. Each junction box consists of a base (with or without standoffs), lid, plug connector cable assembly and socket connector cable assembly or no connector cable assembly for connectorized version.

customized specific gravity alloy parts manufacturers|Customized High Specific Gravity Tungsten Alloy Bar Suppliers