how cnc milling machine works A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for . During remodeling projects, you may need to convert an existing plug-in outlet into a junction box, perhaps if you're going to build cabinets or closets in the area. You must keep the junction box cover accessible, but it's dangerous to simply leave an outlet in .

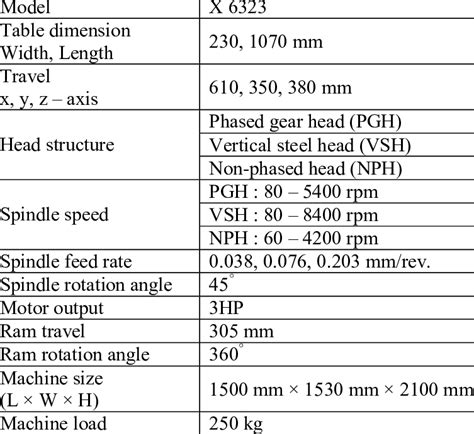

0 · specifications of cnc milling machine

1 · milling process step by

2 · introduction to cnc milling machine

3 · computer controlled milling machine

4 · cnc precision milling

5 · cnc milling process

6 · cnc milling diagram

7 · cnc horizontal milling for dummies

To convert an existing metal building for use as residential space the steps to take are. 1) Check for proper zoning; 2) Get a building permit if necessary, and; 3) Create a renovation plan. Zoning: Zoning rules govern the use of properties located in certain areas.

specifications of cnc milling machine

island style house blue metal roof

A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for .November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. . CNC milling is a computer-controlled process and a specific type of CNC machining that involves cutting a block of material mounted on a machine bed with different rotating multi-point cutters to achieve the desired shape and . CNC milling machines are powerhouses in manufacturing, transforming raw materials into finished products with precision and efficiency. They are employed across various industries to create intricately designed .

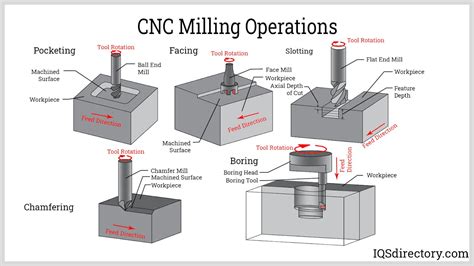

Table of Contents hide. I What is CNC Milling? II Milling Process. III Milling Machine Components. IV Types of Milling Machines. V How Many Axes? VI CNC Milling Operations. VII Suitable Materials. What is CNC Milling? We .

ALLES CNC ALTCK63-1500 CNC turning and milling machine and inclined bed CNC lathe deliveryYou can leave your contact information or contact us.WhatsApp/WeCha. 3. 1.2 Introduction Milling is a cutting operation with a geometrically specified cutting edge in which the tool makes the rotating main movement, and the feed as well as the infeed movement are generally made by the work part. . CNC milling is a fundamental aspect of modern manufacturing. The process involves the use of a CNC milling machine, which operates by interpreting coded instructions to execute complex milling tasks with precision .Milling some parts for a robot, mdf is a good material for milling and not hard. Complete process of milling part.Subscribe, like and share this video.Thanks 👍

CNC Milling Machines. Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. Consequently, the spindle can move across multiple axes (3, 5, or more) to remove the material. . A CNC router machine works on the same working principle as the CNC mill. The difference .

Headquartered in Las Vegas Nevada, our CNC milling department at Viking Machine Works has state of the art Haas CNC mills with capabilities of performing many different milling tasks. Our shop floor has CNC milling with 12,000 RPM spindle speeds for fast milling capabilities in a variety of materials, including aluminum and stainless steel as . 10. Kent USA BM-3 CNC Milling Machine Courtesy of Kent USA. Another CNC Bed Mill is on our list, this time with the Kent USA BM-3. Manufactured in California, this CNC milling machine offers the largest cutting work area out of all the machines we’ve reviewed. The main types of CNC machines are identified as turning centers, milling centers, vertical machining centers, horizontal machining centers, drilling machines, EDM machines, and laser cutting machines. Programming codes like G-codes and M-codes are discussed as well as how CNC machines work through precise positioning coordinates. Read less

milling process step by

CNC工具機銷售達人林明毅個人粉絲頁:https://www.facebook.com/cnc.machine.taiwan/歐美澳全球貿易粉絲頁:https://www.facebook.com/cnc.machine .CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. As one type of CNC machining, it involves mounting the workpiece on a machine bed and cutting materials from a solid block to produce products made of glass, metal, plastic, wood and more specialized materials. Multi-Axis CNC Milling Machine. Multi-axis CNC milling machine can cut at different angles and move along different aces. There are several kinds of multi-axis milling machines: 2-axis milling machines. 2-axis milling machines can work as a workpiece in the x and z axes. Therefore, they can cut vertically and horizontally in one direction. Hello! To kick-start the incorporation of CNC machines courses and programming, you will need necessary and adequately strong machines such as CNC milling machines, CNC lathes, and CNC routers. These machines will provide a solid foundation for your faculty of engineering’s teaching and learning content. Best regards! Reply

A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.

#cncmachiningvideos🔔 Subscribe for more 🔔 https://www.youtube.com/channel/UC1nzmktP1usjdqewrBDN_uQDownload our free guide on CNC machining (pdf) http://3dh.Dashmesh Mechanical Works Main Road Daba Road,101/5, Baba Mukand Singh Nagar Ludhiana - 141003, Punjab, India

Top 10 Most Satisfying CNC Machine In Working. Heavy Duty Vertical Lathe & Mill Turn CenterX-Machines Channelsite: https://www.xmachines-co.com/Fanpage: h. A CNC machine works by following a computer-aided design (CAD) file, which is a digital model of the part or object that needs to be created. This CAD file is then converted into a set of numerical data, called G-code, that tells the CNC machine how to move. . CNC Milling Machine: Used for cutting, shaping, and drilling materials. CNC Lathe . Automatic CNC milling machines; These are used for processing very complex profiles or surfaces. The automatic milling machines are equipped with a probe device that keeps always adherent to the model (copying cutters), guiding the milling head in its movements. . One thought on “How milling machine works” Thomas says: July 24, 2020 at 9: .Based in Sacramento California, PRO Machine Works is the exclusive supplier to many equipment manufacturers nationwide, with quality design and precision machining. With our array of precision CNC machining equipment, we are one of .

3. Introduction to CNC 3 Numerical control (NC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium, as opposed to controlled manually. Most NC today is computer numerical control (CNC), in which computers play an integral part of the control. In modern CNC systems, end-to-end component . ALLES CNC ALTCK63-1500 Slant Bed CNC Lathe and CNC Turning and Milling Machine PackagingYou can leave your contact information or contact us.WhatsApp/WeChat:.

PRECISION CNC MACHINING FOR TURNING AND MILLING. At Lindsay Machine Works, Inc., located right in the midwest in Independence, Missouri, we specialize in providing our customers with precision CNC (Computer Numeric Control) Turning and Milling services. . Advantages of Using Lindsay Machine Works CNC Machine Shop. CNC (Computer Numeric . ALLES CNC ALTCK63-1500 Slant Bed CNC Lathe and CNC Turning and Milling Machine PackageYou can leave your contact information or contact us.WhatsApp/WeChat: +.CNC Control (included with the machine): receives the instructions from the CAM and executes the movement orders of the moving parts of the milling machine according to these instructions. STEP 3: CNC Milling Machine Ready. When the CNC Milling process begins, the tools spin at thousands of RPM – enabling them to cut through materials with ease.11.5" x 8.95" x 0.73" 6061 Aluminum Fixture & Tooling Plate for Bantam Tools Desktop CNC Milling Machines. INCH PLATES: Holes are 0.75" on center. Every hole is tapped 1/4"-20. METRIC PLATES: Holes are 20mm on center. Every hole is tapped M6. The Bantam Tools probing system relies on electrical conductivity between the part and the probe.

Cnc Milling Machine Job Work J K Engineering Works TrustSEAL Verified. Ground Floor, No.39, 8th Cross, Behind Laxmi Naraswamy Temple, Kammagondana Halli, Jalahalli West,, Jalahalli West, Bengaluru - 560015, Dist. Bengaluru, Karnataka. View Mobile Number +91-8046074523. Contact Supplier How The CNC Milling Process Works. CNC milling starts with a concept or design, typically created using 3D CAD software. This machining program allows you to 3D model the object you want to manufacture. The model is the blueprint that the CNC milling machines will use to make the final piece.

how to make a outlet box into a junction box after moving outlet where it is needed consult codes before doing electrical wiring .more.

how cnc milling machine works|computer controlled milling machine