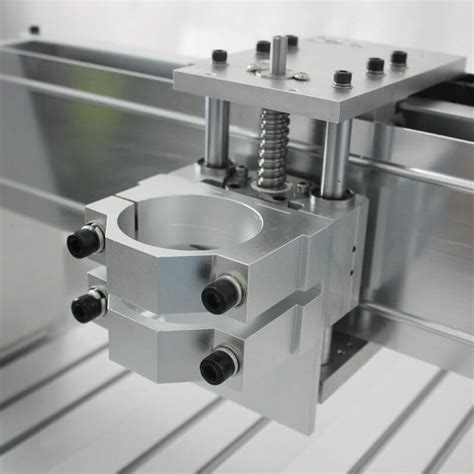

significant parts of a cnc router When you get to the full-scale CNC routers, they start at $50,000 and go up from there. It is far cheaper to build your own CNC router. You can find DIY kits at popular online stores. As mentioned above, building a CNC router will take significant time and knowledge of CNC routers, and it’s important to choose a router kit that will meet your .

Electrical box covers enclose the front of the box and are required by code; it is unsafe, and usually illegal, to leave an electrical box uncovered. Solid or blank covers have no holes and are used with junction boxes or for enclosing unused boxes.

0 · homemade cnc router parts

1 · homemade cnc parts

2 · hobby cnc router parts

3 · cnc supplies parts and more

4 · cnc router parts list

5 · cnc router parts company

6 · cnc replacement parts.com

7 · cnc replacement parts manufacturer

Choosing the right screw size for your outlets and switches is crucial for both safety and functionality. The standard electrical outlet screw size is M3.5 (3.5mm) in diameter, with a length that varies depending on the device and placement of the openings.

homemade cnc router parts

Let’s break down the components most CNC routers have in common: THE BRAINS: Computer System and Controller. It starts with your CAD/CAM .Machine Quality: The build quality of the CNC router plays a significant role. . High precision CNC machines can handle complex parts with tight tolerances. For example, the PROBOTIX™ GX Series machines are designed with high-rigidity gantries, allowing for precision cutting of complex shapes. This capability is essential for industries .Hello! I decided to undertake the process of trying to convert my Ender 3 Pro into a CNC router. First, I know that this frame isn't rigid enough to really handle a router, but I still wanted to attempt it. For me this project was more about .

The frames for your CNC routers are made by CNC frame makers in Jinan, they make a different frame for fibers laser cutters, plasma tables, and CNC routers. The lightest frame for a full table (4’x8’ or 1300x2500mm) will be made out of .

The most significant advantage of using router CNC machining is its accuracy. Computer-controlled machinery can cut materials with extreme precision, which eliminates the need for manual measurements or calculations. . This means that parts made with router CNC machining will be consistently accurate and uniform in size. Additionally, because .

When you get to the full-scale CNC routers, they start at ,000 and go up from there. It is far cheaper to build your own CNC router. You can find DIY kits at popular online stores. As mentioned above, building a CNC router will take significant time and knowledge of CNC routers, and it’s important to choose a router kit that will meet your .CNC routers are an essential part of any machine shop, but building one from scratch is a much more involved project. This guide will walk through all steps necessary for building a CNC Router. . The material of the CNC router is an important consideration. The popular options that work for most of the designs are aluminum extrusion.1. The Basics of CNC Router Machines: CNC router machines are automated devices that are capable of translating design specifications into precise cutting, shaping, and engraving actions on plastic materials. Utilizing computer-aided design (CAD) software, operators can program these machines to achieve intricate designs with utmost accuracy.

Especially for intricate designs, like those created on specialized metal CNC routers, even a small deviation in the Part Zero setting can lead to significant differences in the final product. Additionally, for businesses relying on American-made CNC routers, known for their sturdy build and advanced technology, maintaining the integrity of .

Let’s start by looking at the more technical parts of CNC routers. All CNC machines, whether a miller, laser, plotter, waterjet or router, all share a common aspect – the axes of movement. . CAD CAM is a term you will hear a lot of when looking at CNC routers so it’s important to understand what the terms mean. CAD (Computer-Aided . With these capabilities, CNC routers can offer more effective cuts than manually-controlled routers, with a significant increase in productivity and efficiency. CNC routers are able to generate an exceptional variety of customized parts with accuracy and precision, and the automation process provides ease of operation and offers results such as .

Before diving into using a CNC router machine, it's important to have a basic understanding of its components and how it functions. We will explore the main parts of a CNC router, including the frame, spindle, motors, and control system. Additionally, we will discuss the different types of CNC router machines available on the market, as well as . A bit is one of the most important parts of a CNC router – but the wide variety of different shapes, sizes, and functionality can mean it’s difficult to know where to start. I’d recommend the Mcwdoit 40 Piece End Mill Bits Set as the best router bit set for beginners, balancing precise cutting ability, resistance to wear and tear, and material versatility for an . 5 axis CNC routers can achieve high-precision processing of molds to ensure the accuracy and surface quality of molds. Whether it is an injection mold or a die-casting mold, a 5 axis CNC router can provide high-efficiency and high-precision processing services. 5 Axis CNC Router for Mold Carving What are the important points for a CNC router that will be cutting metal? Rigidity! . What flow process does 1678 use to make their CNC parts? Once we have the CAD of a given part we convert the faces to be machined to .DXF format to use with our CAM software. Occasionally we have a part with a lot of features that is difficult to generate .

A simplified diagram of the Roctech CNC Router is seen below. The diagram is labelled and some information is listed explaining the main parts of the duet and what they do. 1. Using an A4 piece of. When selecting a DIY CNC router kit, it’s important to consider factors such as the size of the machine, the cutting area, and the level of technical skill required to assemble the kit. . We recommend cleaning your CNC router .

homemade cnc parts

Diligent CNC router maintenance is essential for ensuring that these complex machines operate at peak efficiency and have extended lifespans. By incorporating regular cleaning, precise lubrication, and thorough inspections . The FoxAlien CNC router is a device that has a 300-watt spindle and stepper motor, which makes it all the more powerful and efficient. Producing maximum moving speeds and featuring a spindle speed range with a max of 10,000, this CNC router comes with a newly designed box, control board, power supply, and emergency stop. Computer Numerical Control (CNC) machining has become an important part of many manufacturing companies today. Manufacturers have been able to produce devices and machine components that adhere to the strictest quality standards and properly function in their intended applications, all through the versatility, speed and precision of CNC machines. Read-on to understand the parts of a CNC milling machine and their functions. Also know about different accessories and tools used with milling machines. . Rotary kits are also available for entry-level CNC routers and mills to engrave parts such as furniture legs, tumblers, etc. . it is important to understand your requirements and select .

For more information, see our guide on CNC Machining. Some Common CNC Router Accessories. CNC router accessories include many categories of equipment, including a surprising number of tools and accessories – of wide-ranging cost and usefulness. These are: 1. CNC Router Bits “Bits” is a catch-all term for a wide range of drills and cutters.

56 THE COMPONENTS OF A CNC ROUTER Work Holding In order to machine a part on a CNC router the part must be held securely in place. This seems obvious, however, this is the one area that often causes major headaches. . The hold-down system has a significant impact on part accuracy, quality of finish and on feed speeds and tooling life. Keep in . Besides your CNC machine itself, the next most important part of machining is the router bit. Different bits make different cuts and have different jobs, and if you’re new to machining, navigating bits can be confusing.When using a CNC router, it's important to understand that certain issues can arise during the manufacturing process. These may include burrs and sharp edges on the machined parts, which can be a result of the cutting process. These will need to be explained to our customers, as they may require additional finishing or deburring to achieve the . The most important factor in buying a CNC router is rigidity. Poor CNC rigidity is the dominant issue in cheap 4×8 CNCs, and generally the more rigid the CNC, the more expensive it is (at least up to ,000). . Furniture: building furniture involves cutting many parts. A 4×8 plywood CNC machine is the best tool for this since it minimizes .

The software used to design and control your CNC router is just as important as the machine itself. Ensure that the CNC router you choose is compatible with the software you plan to use. . When designing your projects, consider how you can arrange your parts on the material sheet to minimize waste and maximize material efficiency. Aluminum crafting with a CNC router opens up opportunities for creating durable and precise parts for hobbyist projects, such as custom drone frames or robotic components. . It’s important to choose a CNC router with the right spindle power for your specific needs, whether it’s intricate wood carving or cutting through denser materials. Q .

Looking for a welder for sheet metal? We found 5 best welders for doing it that don't cost a fortune - check them out in our article.

significant parts of a cnc router|homemade cnc router parts