mill finish cnc parts factories CNC turned parts Manufacturers, Factory, Suppliers From China, We believe in quality over quantity. . more than 150 sets milling machines and CNC centers,over 350 well-trained employees and ISO9001:2015 certification, our company has the expertise and knowledge to produce the highest quality machined parts . Process:CNC machining, CNC . This antique W.B. Mfg Co. Weidlich Brothers art nouveau jewelry box/trinket box is a stunning piece from the early 20th century (1911-1940). See more details in photos. It is an excellent addition to any collection of boxes, jars & tins or decorative collectibles.

0 · what is cnc machining

1 · surface finishing for cnc

2 · surface finish for cnc parts

3 · surface finish for cnc cutting

4 · surface finish cnc machining

5 · cnc machining finishes

6 · best surface finish for cnc

Deburring & Finishing - VTS Sheetmetal Fabrication

You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish . Whether it’s bead blasted, anodized (Type II, Type III), chromed, powder coating, or zinc plating, 3ERP has the expertise and capabilities to deliver top-tier finishes for a wide variety of CNC machined parts. Our dual CNC .High-Quality Lustrous Satin Finish (Paint) Services. Satin Finish Service at CNCLATHING.COM is capable of delivering precise and uniform metal surfaces, focusing on performance and .CNC machining surface finish: Blue anodised. CNC machining surface finish, on the other hand, describes the state of the finished parts’ surface, as well as the process involved in achieving that state. It refers not only to the texture or look .

CNC turned parts Manufacturers, Factory, Suppliers From China, We believe in quality over quantity. . more than 150 sets milling machines and CNC centers,over 350 well-trained employees and ISO9001:2015 certification, our company has the expertise and knowledge to produce the highest quality machined parts . Process:CNC machining, CNC .RALLY provides quality CNC milled parts services. Our custom design support ensures that each customer's unique vision is transformed into a tangible reality that maintains precision and conforms to specifications. In addition to initial .FIFTH METAL is one of the most professional cnc milling parts manufacturers and suppliers in China. If you're going to buy high quality cnc milling parts, welcome to get free sample from our factory. . and in most cases the part is machined from start to finish in a few minutes. Multi-axis milling machines can form multiple part features on . Passivation is a common post-processing technique used in CNC machining finish to improve the surface quality and performance of parts. After the machining process, the surface of the part may have micro-roughness or surface impurities that can negatively impact the part’s performance over time.

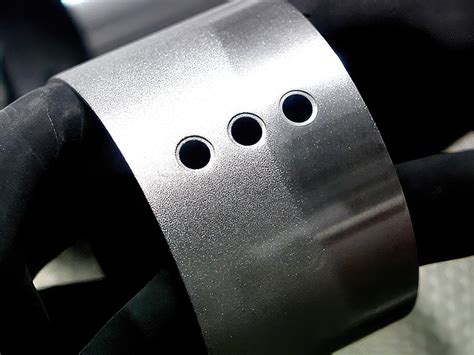

Focusing on manufacturing, characteristics, and applications within mill finish surfaces is quite technical. However, with this level of detail, you can trust what’s being said. The source was published in a prestigious industry journal that centers around developments, trends, and technical information on stainless steel!Description: The as-milled finish is the default surface finish after the CNC milling process. It retains the tool marks and patterns from the cutting tools. Surface Roughness: Typically between Ra 3.2 μm to Ra 6.3 μm. Applications: Suitable for internal components or parts where surface aesthetics are not critical. Common in prototyping and .Bomei is a one of the best custom precision milling turning parts manufacturers, provide a one-stop custom machining service, which save cost and time for your industrial product parts manufacturing. +86-18925741509 [email protected] a leading CNC parts manufacturer, we understand the importance of achieving a flawless mill finish. In this blog post, we will explore the significance of mill finish, techniques to achieve excellence, and the benefits it brings to the overall manufacturing process. The Importance of Mill Finish. Mill finish refers to the surface finish of a .

what is cnc machining

Improved Surface Finish: CNC milling can provide a different type of finish compared to turning. For instance, while turning can produce a very smooth surface finish, milling can create a textured finish if needed. By combining both, manufacturers can achieve the desired surface characteristics in different regions of the part.

Understanding Surface Finish and How to Measure it. Surface finish is an important consideration when manufacturing parts. It affects the appearance, wear, and lubricity of the part. There are three parameters that distinguish a surface finish lay, roughness, and waviness. Aluminum finishes are crucial in enhancing the performance and aesthetics of CNC parts made from this versatile metal. Designers and manufacturers widely favor aluminum for its remarkable strength-to-weight ratio, good thermal and electrical conductivity, and excellent corrosion resistance. . For instance, a mill-finish aluminum surface is .

The mill finish for stainless steel is the default finish that is achieved through the manufacturing process. It is a rough and inconsistent surface finish with a surface roughness range of 1.5 to 3.5 micrometers. The mill finish is suitable for applications where aesthetic appeal is not crucial, such as industrial uses. When you combine EMUGE-FRANKEN USA tooling with Siemens programming, the end product is a masterpiece with excellent surface quality!! These two partners at IMTS 2024 are working together to showcase solutions that bring some fantastic results for customers. Tune in with Arthur Field of MTDCNC in a special feature with Kent Hohensee of EMUGE . Common Finishes for CNC Machined Parts As-Machined. CNC machining produces a part with an “as-machined” or “as-milled” finish as soon as the manufacturing process is completed. The part will have small but visible . Optimize CNC parts with 10 aluminum finishes. Enhance corrosion resistance, durability, and visual appeal for custom components. . Surface finishes are important for increasing the life and performance of aluminum .

surface finishing for cnc

Item Name: Custom brass milling parts; Craftsmanship: CNC milling; Finish: / Price: Real Instant Factory Price; Packing: PE. . China precision brass milling parts suppliers, factory, Electrical Stamping Die, Custom Brass Parts, Small .

So having a heck of a time finding images or video comparing the two. Making prototype parts, so its not essential to have the perfect mirror finish. More of a proof of concept normally. My question is, before I run this massive material clearing part, how rough of a finish does a 'roughing'.Boyi CNC turned stainless steel parts has perfect finish and tight tolerances, widely used in medical, automotive, optical, mechanical industries. . complex stainless steel CNC milling parts, Boyi CNC milling service will never let you down. We have advanced 3-, 4-, 5- axis CNC milling centers to help customers’ stainless steel CNC milling .

what are the steel boxes in mario odyssey

These areas have a surface finish callout of 32 / 16. My main question regards the do-ability of that finish spec via interpolating on the mill. Our mill is a HAAS Super VF-3. We also have available a HAAS ST-30 Lathe (no live tooling). The nature of these parts make mounting them in the lathe a chore so I was hoping to do all the work on the mill.2.1 Mill Finish. Explain what mill finish entails, its characteristics, and common uses across different industries. Discuss the pros and cons of this type of surface finish and when it is the preferred choice. 2.2 Brushed Finish. Detail the process of creating a brushed finish on steel surfaces, highlighting its unique texture and visual appeal.

Therefore, machinists must finish the parts using surface finishing processes to solve this shortcoming. These processes typically remove a very small amount/layer of the material from the surface, measuring a few micrometers or nanometers. This section covers the various processes of achieving the desired CNC surface finish. 1. GrindingMaking your own mill finish cnc parts tool. Mill Finish CNC Parts manufacturer. Making your own mill finish cnc parts tool is a simple job that can be done by anyone. We have provided all the necessary information to build a mill finish cnc part tool, so you don't need to . CNC Milling: CNC milling involves using rotating cutting tools to remove material from the workpiece. CNC milling machines can move their tools and workpieces in multiple directions, allowing for the creation of complex shapes and features. . Surface Finish: Parts produced by CNC machining typically have a superior surface finish that may not .

Our precision C NC machining services provide rapid milling and high accuracy to manufacture custom metal and parts. Our CNC Machines are able to quickly cut 2D and 3D parts with high precision – no matter the part or prototype.. Our machine shop provides access to 3-axis, 4-axis, 5-axis milling with 90 degree capabilities. With our various machines, we’re able to create and .A CNC machined part isn’t done once the machine stops running.. Finishing is the final step in the manufacturing process (outside of assembly) and involves various techniques to improve your parts’ appearance, functionality, and durability. The finishing process is crucial to achieving the desired properties of your machined parts. This article will explore some of the most popular . Learn the basics of CNC milling parts with our comprehensive beginner's guide. Discover how CNC milling works and why it's essential for precision manufacturing. . CNC milling is a powerful manufacturing process that offers precision and versatility. Whether you’re a hobbyist or a professional engineer, understanding the basics of CNC .

surface finish for cnc parts

surface finish for cnc cutting

surface finish cnc machining

cnc machining finishes

The WAGOBOX XLA general purpose electrical enclosure is designed to be used with the WAGO 222 and 773 series connectors. Rated up to 450V AC / 41A Supports conductor sizes from 0.08mm² to 6mm²

mill finish cnc parts factories|cnc machining finishes