sheet metal dimensioning standards The ASME Y14.5 standard establishes symbols, definitions, and rules for geometric dimensioning and tolerancing. The purpose of the standard is to ensure clear communication . Unlike a traditional box spring, this cleverly crafted foundation is made with a thick and sturdy steel frame for ultimate strength and longevity. Build It, Stress-Free. All tools, parts and instructions are conveniently packed into one box for set-up that takes less than an hour with a friend's help. Now that's what we call smart!

0 · sheet metal layout drawings

1 · sheet metal gusset design guidelines

2 · sheet metal design guidelines pdf

3 · sheet metal bending drawing

4 · sheet metal bending chart

5 · sheet metal bending basics

6 · minimum flange length sheet metal

7 · maximum thickness sheet metal bending

#22 End Boot. #23 Str Boot. #24 Plaster FramesFor nearly 50 years, ZM Sheet Metal has been committed to delivering top quality that’s ahead of its time. We’re a family business, and it shows. We treat our clients the way we would expect .

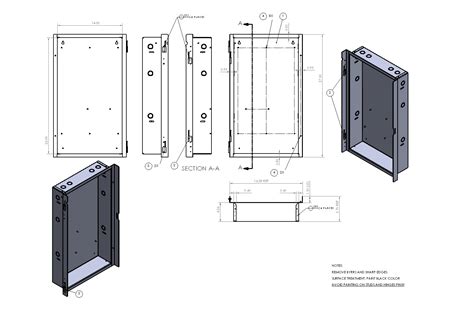

Some critical dimensions that need to be considered when setting up sheet metal in CAD software are sheet metal thickness, the k-factor, and bend radius. One needs to check that these factors are consistent with the tooling that will be . The ASME Y14.5 standard establishes symbols, definitions, and rules for geometric dimensioning and tolerancing. The purpose of the standard is to ensure clear communication .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

facebook desart metal fabrications

See document 10-0005, Blah Drawing & Drafting Standards and Practices, for the proper setup of a sheet metal drawing. For door panels, front panels, interior panels, and racks see document . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Sheet Metal Bending Guidelines Explained | MachineMFG. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high . Dimensioning standard for sheet metal part 3. Thread starter cinnamongirl; Start date Jun 14, 2016; Status Not open for further replies. Jun 14, 2016 #1 cinnamongirl Mechanical. Jan 18, 2011 106. I was given several sheet metal parts, they are basically U-shaped with three flat sides. I know the standard is to dimension the outside of the part .

Dimensioning in 2D Drawings for Sheet Metal Fabrication. Accurate dimensioning is crucial for successful sheet metal fabrication. Here are some common elements related to dimensioning that you’ll find in 2D drawings. 1. .

← Preventing Common Press Brake Mistakes: Bend Radius for Sheet Metal Sheet Metal Layout Tip: Dimension to Formed View, . Standard Enclosures (9) Supply Chain Management (6) TruMatic 6000 TRUMPF (2) UL Ratings (1) . Sheet metal dimensioning standards. Discussion in 'SolidWorks' started by SW Monkey, Dec 28, 2004. SW Monkey Guest. Anyone know where I can get some examples and standards for dimensioning sheet metal drawings? I have some pretty complex parts that need to be bent, and they have about 8 bends that are on differentFor example, cnc turret punch press machines have standard tooling that make cutting certain geometries very inexpensive. More custom shapes may warrant extra processing or the development of custom tools to manufacture at volume. . and properly formatted dimensioning. A fully dimensioned sheet metal drawing includes dimensions for all bends .

The sheet metal part designers need to consider the range of possible product dimension changes during the in sheet metal design process. If the part dimension variation range is not suitable, such as if the tight tolerances, then a more precise manufacturing process is needed to ensure the accuracy of the finished product.Guiding Companies Across the Product Development Lifecycle. ASME's Y14 standards guide you across the product development process, from concept through to delivery, empowering you to deliver solutions that meet and exceed performance criteria. Their established language and methodology have become the framework for much of today's production, inspection and . This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.The basic dimensions are nominal dimensions of a metric thread profile without allowance and tolerances (The thread class defines that). They are based on standard ISO 68-1. The basic dimensions can be used for design. However, for manufacturing and machining, you need the allowable range of each dimension.

Ask questions about CAD software, drawing standards or just show off your latest project. Members Online • s_0_s_z . It is mostly pointless to dimension sheet metal features to the outside. I think I have been overkill with dimensions, quite honestly because again, I am more used to machined parts where you need to dimension every feature .

Gauge size chart for sheet metal. Filter for standard steel, galvanized steel, stainless steel, zinc, or birmingham gage. Login | Register for free! . Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size .Dimension from the edge of the flat sheet metal? Dimension from the flat edge of the final product? . AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines.Standard Sheet Metal is an industry leader in architectural, commercial, and industrial metal fabrication & manufacturing custom steel components. Standard Sheet Metal Toggle Navigation

Which is the best practice while giving dimensions for a sheet metal bracket. 1. Taking the fixing holes as a reference dimension and dimensioning the other features based on this fixing hole? 2. Taking some other flat surfaces as base reference and dimensioning all other features including the.

What is Gauge in Sheet Metal Fabrication? In the fabrication industry, ‘gauge’ is an identifier for the standard thickness of sheet metal of a specific material. The gauge size is based on the weight of the metal sheet . When dimensioning sheet metal products, do it in a manner that makes it easiest to inspect the final product. Don't worry about the fabricator. Remember if you do outside dimensions the fabricator has to deduct the material thicknesses and bend allowances, whereas with inside dimensioning he/she merely has to add the bend allowances , however .

Technical standards and manuals developed by SMACNA members have worldwide acceptance by the construction and code community, as well as local and national government agencies. ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. . This indicates that the actual dimensions of the finished part may slightly undershoot the specified measurements in the design. . the design of bends and flanges is instrumental in .• Minimize offset dimension. • Form angle, offset dimension and overall shape of emboss are all factors that impact manufacturability. [email protected] | 607.227.7070 | www.incodema.com • Adds strength. • May be used for clearance. • May be used as a standoff feature. The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and .

Drafting Standards, GD&T & Tolerance Analysis . Why dimension sheet metal flat patterns? 1 . . Why dimension sheet metal flat patterns? 1. Thread starter STeliczan; Start date Jun 12, 2014; Status Not open for further replies. Jun 12, 2014 #1 STeliczan Mechanical. Apr 23, 2014 3 US. I'm looking at an opportunity to save time on drafting parts .Study with Quizlet and memorize flashcards containing terms like The current dimensioning standard requires that diameter dimensions be shown as in the following example:, A flat on a shaft must be dimensioned by specifying the distance from the ___, A dimension showing the location of a ruond hole must be applied to ____ and more.For dimensions measured over mul-tiple bends, Xometry can offer a +/- 0.030” (0.762mm) tolerance. Simple Bend / One Surface When designing parts with some type of bend with a standard bend radius, sheet metal tolerances are required to open. For simple bent parts, Xometry can offer a +/- 0.010” (+/- 0.254mm) tolerance for dimensions 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.. Selection .

fancy wire junction box

Material Dimensions mm: 1220 x 2438 or 1220 x 3048. Specifiers should consider the most economical use of these standard sizes before designing a project. If the intended metal facing has formed edges, the overall standard blank size should always fall within the above dimensions. Standard sheet size for PVD coated stainless steel is 48″ x 96 . HANSEN SHEET METAL 10 Hansen Industries Ltd | 2871 Olafsen Avenue Richmond, BC|Ph:6042782223|Fax:6042787733 Bends. Bends in sheet metal are manufactured using brake presses. Hansen will hold a +/-1-degree tolerance on all bend angles. Hansen preferred bend radius is .0. Other standard bend 32" I have a very basic sheet metal part (made by someone else - my job is to dimension it) that I'm in the process of dimensioning. The part looks very simple, however when I examine it closely, the bottom lip isn't perfectly horizontal.could this be a mistake on their end and I should dimension it as if the bottom lip is at a horizontal bend?

sheet metal layout drawings

famous metal fabricators

sheet metal gusset design guidelines

sheet metal design guidelines pdf

Shop Full 7.5'' No Assembly Metal Box Spring - Zinus at Target. Choose from Same Day Delivery, Drive Up or Order Pickup. Free standard shipping with $35 orders.

sheet metal dimensioning standards|maximum thickness sheet metal bending