junction box orientation on electric motor NOTE: For all NEMA mounting configurations, refer to NEMA MG 1-2009. NEMA Mounting Arrangements BEC-402 I’m gathering up wooden boxes for winter projects I can do inside. I have enjoyed seeing all the magic you do with your finds. I found a long narrow case that was for music stands and brought it home (someone had thrown it away!), now that is going to be a challenge!

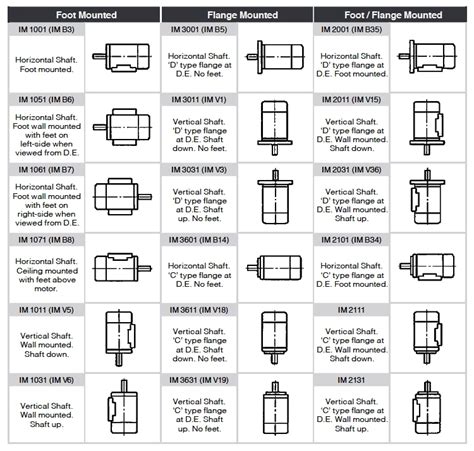

0 · motor mounting positions

1 · motor mounting position code

2 · motor mounting codes pdf

3 · left or right motor motor

4 · electric motor mounting codes

5 · bec 402 motor mounting diagram

6 · abb motor mounting diagram

7 · abb motor mounting arrangements

steel box section - rhs rectangular hollow section, cold and hot finish from stock. square hollow section. Mild steel (inc. S355) box section supplied to the construction industry .

F-1: J-box is on right when you straddle the motor and the shaft is straight up. (Or look at the j-box on the side of the motor and the shaft is extending out the end on the right.) F-2: J-box is on left.The standard IEC mounting position places the junction box on the top of the motor, known as the IM B3 mounting position in IEC frame (or F3 in NEMA frames). On the other hand, the NEMA standard mounting position is referred .

cnc machining casting factories

NOTE: For all NEMA mounting configurations, refer to NEMA MG 1-2009. NEMA Mounting Arrangements BEC-402F-1 = Conduit box on right-hand side of frame when facing “front” of motor. F-2 = Conduit box on left-hand side of frame when facing “front” of motor. The conduit opening can be placed in any one of four positions by rotating the conduit box .Motor Mounting Types. Overview/Objectives: Mounting Types and Their Uses. Industry Dimensional Standards Overview and Comparison.

The following order information is required for R, F, K and S gear units and gearmotors in addition to the mounting position to exactly determine the design of the drive. This information is also .

cnc machining companies in california

When swapping out a replacement motor, it’s tempting to unbolt the J-box (junction box/terminal box/ T-box) from the motor and leave it attached to the conduit. The problem with doing so is that the motor manufacturers .Electric motors contain dangerous rotating parts. Fatal or severe injuries and substantial material damage can occur if the covers are removed or if the motor is not handled, operated, or .Ball Bearings Belts Carbon Brushes Cord & Lead Wire Electric Motor Accessories Electric Motor Parts Electric Motors Electrical Components Enclosures Generators Harvestor Silo Unloaders Outer Wear Phase Converters Power Tool Accessories . 003202.01 Leeson Junction Box. MFG: Leeson Electric (Regal Rexnord) 003202.01. Temporarily out of stock .on a bus bar in the terminal box. Insulating the joint For motors operating at less than 2kV, kits are available to insulate the Figure 2. Line lugs terminated on bus in outlet box. Figure 3. Crimp type compression lugs. Figure 4. Crimping tool & dies. Photo courtesy of Eaton’s Power Systems Business. Motor terminal box connection methods .

cnc machining center camprocnc

I am looking for an industry standard as it relates to motor junction boxes: cable entry . I am looking for an industry standard as it relates to motor junction boxes: cable entry, size, orientation etc.. Replies continue below Recommended for you. RE: MOTOR JUNCTION BOX STANDARD GordS (Electrical) 25 Sep 02 14:02. NEMA MG-1 offers some .

× Close Quote creation for third-party products. ok . I plead guilty to removing the peckerhead box entirely, (Monarch 10EE ""large frame" Reliance DC motor) drilling some holes, sleeving them, and re-routing the wires to a much smaller "feature" (Conduit Ell, thence Hubbell male Twist-lock).Motor junction box Top cover plate Side cover plate JucntionBox Kit Screw Sizes (English/Metric) 1326AB-MOD-RJBC two 4-40 x 0.5nich screws egiht 8-32 x 0.5nich screws six 6-32 x 0.5 inch screws two 10-32 x 0.5nich screws 1326AB-MOD-RJC1 two M3 x 16 mm screws Also of course if rotation was correct in original orientation then a lead swap is required for new orientation. There may be auxiliary junction boxes for space heater or rtd to think about. Since it's a congested area make sure any air ports (side or end for odp, end for TEFC) are not blocked by whatever is next to the motor.

Electric brakes and clutches are good examples. fifty60 Senior Member. Location USA. May 28, 2014 #6 . In the NEC there is a section requiring a motor junction box, it's just indirect because it is mentioned in the section on grounding of motors, 430.245.

Junction Box Inspection and Test Plan Task Vendor TPI Inspection Client; Junction Box Mill test reports: H: R: R: Junction Box Ancillary items (Bolt, Nut, TERMINALS, ETC.) H: W: R: Junction Box Check all electrical connections, wiring and conduit installation: H: S: R: Junction Box Degree of Protection: H: W: R: Junction Box Final visual .

What I would like to do is have my fab shop beef up the back of a hoffman type 24x24x12 Nema 4x j-box, (motor is outside) and cut the mounting patteren into the back of that. Then I could use the factor gasket and mount the box directly to the motor, then I would have room to make the terminations.× Close Quote creation for third-party products. ok .

motor mounting positions

motor mounting position code

Our Motor testing program is in it's infancy- we have the Baker AWA and want to conduct testing on the 4160V and larger motors. We have hit a roadblock as the system engineers- electrical are concerned that conducting the Baker DC- Hipot test from the circuit breaker will age or prematurely fail the power cable from the circuit breaker to the motor .Junction boxes house wiring connections and terminal boxes house the connections between lead wires from the motor and feed wires from a source of electricity. Terminal boxes are not designated for specific motors, but determined by volume. Call us at (800) 438-3003 for questions on specifications. What is the box on the side of a motor called .

A junction box is an enclosure that protects a connection of two or more wires carrying electrical current. Every electrical connection should be inside a protective box that is easy to find and access. Junction Boxes are Metal or Plastic. . Electrical .

motor mounting codes pdf

Another area that often causes confusion on outline drawings is naming conventions for both motor components (for example, junction box versus peckerhead or top hat versus air cabinet) and directional labels (for example, .When it comes to Motor Conduit Boxes, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support. . also known as terminal or junction boxes, mount to the frame of the motor and enclose and secure the motor's electrical connections. Motor "Peckerhead" Orientation. Thread starter DannyT. Start date May 13, 2024; D. DannyT. Member. Location US Occupation Service Tech . Motors, except for hazardous locations, are not UL listed, motor junction boxes have a minimum volume in the NEC, so the orientation is not an NEC issue . infinity Moderator. Staff member. Location New .

In NFPA 79-2007, Clause 13.5.9.2 states, "Electrical connections at motor terminal boxes shall be made with an identified method of connection. Twist-on wire connections shall not be used for this purpose." What I think this means that wire nuts cannot be used in motor 'potheads'.

In motors with excessive vibration, we terminate and tape them as we would normally do, and then pack the motor junction box completely full of duct seal to prevent any movement of the wires inside the junction box. The duct seal is also packed into the end of the liquid tight flexible conduit connection to the motor junction box. Mid-morning on the job and Ted, an electrician, directs Jim, his new apprentice “Now we are going to start installing the sealtite from the starters to the motors.So go ahead and cut the whips to length, making them long enough to include some drip slack. Then go get some fittings and open up the peckerheads.”

(Polaris or Burndy style insulated connectors). Either they are not approved for motor use, or are so large to accomodate a 12 lead - 3 phase, 30 HP motor that they won't fit in a motor junction box, due to the fact that the terminals are only rated for one conductor per terminal.A junction box for a motor vehicle electrical system for coupling electrical leads extending to the rear of a vehicle with leads extending to the front of a vehicle, comprising a moulded body having various component parts, notably a tray member, one end wall and a bottom wall, constructed separately and carrying connector blocks for flat pin connector terminals; the connector blocks .When it comes to NEMA 56 Motor Conduit Boxes, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support. . also known as terminal or junction boxes, mount to the frame of the motor and enclose and secure the motor's electrical connections. Clear All.

3.5 Motor Terminal Boxes and Leads 3.5.1 Motors shall be fitted with an oversized, cast iron, main terminal box. The box shall be arranged so that conduit can enter from the bottom. Gaskets shall be supplied between the box and motor frame as well as between the box and its cover. As standard, the box shall be mounted on the right hand side .

Consult Winkelmann Elektromotoren GmbH & Co. KG's Position of terminal box and direction of rotation following EN 60034-7 / EN 60034-8 brochure on DirectIndustry. Page: 1/1. Exhibit with us {{>currencyLabel}} Back . AC motor; Synchronous motor; Asynchronous motor; Three-phase motor; IP55 motor; Protection level motor; Permanent magnet motor . The purpose of this procedure is to ensure that all works regarding electrical junction box and supports installation for electrical instrumentation works shall be done in accordance with the applicable local standards and all other applicable international codes and standards.. Scope of work covers the steps to be followed for the junction box and support .National Electrical Manufacturers Association • Common within North American market. • NEMA Standards Publication MG 1-2011 for Motors and Generators is specification title. . o Integral and Large AC Motors –First two digits / 4 = “D” dimension in inches –Third Digit (and fourth) = Relative Length - 2F Dimension

cnc machining chattanooga tn

cnc machining center manufacturer in germany

On normal electrical boxes, screws are usually 6-32. this being a bit light for a fan, also expect 8-32 or 10-32. Ground screws are 10-32. It's not a coincidence that they are -32, given the thickness of standard metal junction boxes, that is the minimum number of threads to properly engage. Never use sheetmetal screws.

junction box orientation on electric motor|bec 402 motor mounting diagram