cnc machine cutting parameters Learn about the essential parameters of a CNC machine, from spindle speed to cycle time, to maximize efficiency and precision in your machining operations. Valley Metal Works provides all-in-one custom metal fabrication, design assistance, and optimization. We specialize in working with small to medium-sized ODMs and OEMs to manufacture custom products done right—the first time around.

0 · types of cnc parameters

1 · cnc parameters explained

2 · cnc parameter settings

3 · cnc machining parameters list

4 · cnc machining parameters explained

5 · cnc cycle parameters

6 · best cnc parameters

7 · 7 cnc parameters

For 20 years WoodTurningz has offered innovative wood pen kits, exotic wood pen blanks, and our exclusive Inlace Acrylester™ turning blanks. In addition, we carry a wide range of woodturning supplies for every woodturner. Since the beginning, our .

By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different .

Learn about the essential parameters of a CNC machine, from spindle speed to cycle time, to maximize efficiency and precision in your machining operations.

types of cnc parameters

cnc parameters explained

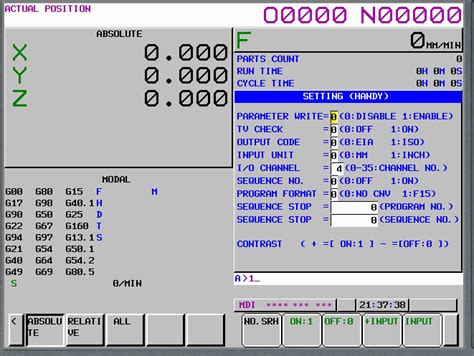

In this article, we will delve into the world of CNC machine parameters, exploring their significance, and providing practical insights to help you master them. 1. Spindle Speed:\ The . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .Each cutting tool is defined by a number of these standardized ISO 13399 parameters. The standard provides cutting tool information in a neutral format that is independent of any particular system or company nomenclature. The main CNC machining parameters include cutting speed, spindle speed, feed rate, depth of cut, and others. Each of these parameters significantly impacts the machining process and the quality of the final product.

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different materials, and the methods for optimizing parameter settings, you can enhance production efficiency and product quality.Learn about the essential parameters of a CNC machine, from spindle speed to cycle time, to maximize efficiency and precision in your machining operations.This page explains the formulas for calculating the cutting speed (vc), feed (f), machining time (Tc), theoretical finished surface roughness (h), net power (Pc), and Kc Values (Cutting), giving examples to help your understanding. “Introduction to Machining” is a site where users can learn about machining. This site is managed by KEYENCE CORP.

In this article, we will delve into the world of CNC machine parameters, exploring their significance, and providing practical insights to help you master them. 1. Spindle Speed:\ The spindle speed refers to the rotational speed of the cutting tool. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .Each cutting tool is defined by a number of these standardized ISO 13399 parameters. The standard provides cutting tool information in a neutral format that is independent of any particular system or company nomenclature.

Calculate Cutting Speed (SFM), Chip-Load (ipt), RPM, and Feed-Rate. Reference data for FHS, SHCS, Heli-Coil, Pipe Taps, Scientific Calculator, Bolt Hole, etc. Select the Tool Type drop-down to pick a proper tool for the job. Then enter proper tool geometry and cutter engagement. Click on the toolbar to get more insights about your cutting data. In CNC machining, the selection of cutting tools is crucial for efficiency and accuracy. This article dives into the principles of choosing the right tools and cutting parameters, discussing factors such as material types, tool structures, and specific machining requirements. The main CNC machining parameters include cutting speed, spindle speed, feed rate, depth of cut, and others. Each of these parameters significantly impacts the machining process and the quality of the final product.

Parameters tell the CNC every little detail about the specific machine tool being used, and how all CNC features and functions are to be utilized. By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different materials, and the methods for optimizing parameter settings, you can enhance production efficiency and product quality.Learn about the essential parameters of a CNC machine, from spindle speed to cycle time, to maximize efficiency and precision in your machining operations.This page explains the formulas for calculating the cutting speed (vc), feed (f), machining time (Tc), theoretical finished surface roughness (h), net power (Pc), and Kc Values (Cutting), giving examples to help your understanding. “Introduction to Machining” is a site where users can learn about machining. This site is managed by KEYENCE CORP.

cnc parameter settings

In this article, we will delve into the world of CNC machine parameters, exploring their significance, and providing practical insights to help you master them. 1. Spindle Speed:\ The spindle speed refers to the rotational speed of the cutting tool. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .Each cutting tool is defined by a number of these standardized ISO 13399 parameters. The standard provides cutting tool information in a neutral format that is independent of any particular system or company nomenclature.Calculate Cutting Speed (SFM), Chip-Load (ipt), RPM, and Feed-Rate. Reference data for FHS, SHCS, Heli-Coil, Pipe Taps, Scientific Calculator, Bolt Hole, etc. Select the Tool Type drop-down to pick a proper tool for the job. Then enter proper tool geometry and cutter engagement. Click on the toolbar to get more insights about your cutting data.

cnc machining parameters list

cnc machining parameters explained

cnc cycle parameters

best cnc parameters

★ 17 years CNC parts machining factory ★ The highest precision can reach 0.001mm ★ ISO certified, high quality, high accuracy ★ 50+ professional CNC engineers at your service ★ Provide CNC machining services for American .

cnc machine cutting parameters|types of cnc parameters