cnc machine hour rate calculation ppt Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on .

What Do Sheet Metal Gauges Mean? Where Did Sheet Metal Gauges Come From? How to Read & Use a Sheet Metal Gauge Chart? Why Do Sheet Metal Gauges Matter? 14 Gauge or 16 Gauge Steel – Which is More Thicker? 1- How thick is 20 gauge sheet metal? 2- How big is 22 gauge sheet metal? 3- Is 18 or 20 gauge thicker? 4- Which is thicker, 24 or 26-gauge metal?

0 · machinery cost per hour calculator

1 · machine hour rate calculation formula

2 · machine hour rate calculation excel

3 · machine cost per hour formula

4 · cnc router cost per hour

5 · cnc milling cost per hour

6 · cnc machine cost per hour

7 · calculating machine cost per hour

A junction box is an essential component used in electrical wiring to connect and protect multiple wires coming from different directions. It is an enclosure that includes terminal blocks, which enable the safe connection of .

The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The . The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The . It also covers drilling, boring, milling, shaping, planning, grinding, and provides formulas for calculating machining times based on factors like tool travel, feed rate, depth of cut, rpm, and cutting speed. This unit covers the definition and concepts related to Machine Hour Rate (MHR), including the steps for computation and allocation of overheads.

The document discusses machine hour rate, which is a method used to absorb factory overhead costs into production. It defines machine hour rate as the cost of running a machine per hour, calculated by dividing total overhead costs .

Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on .As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining .

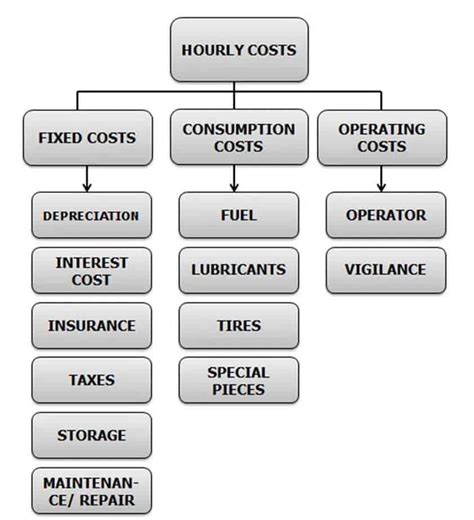

Understanding the importance of CNC machine hour rate calculation is crucial for manufacturers. It helps in accurate cost estimation, determining optimal pricing strategies, evaluating project . The calculation of the machine hour rate includes depreciation, repairs and maintenance, power, steam, and water use charges, factory rent, rates, and insurance, factory lighting, factory supervision, and machinery .

machinery cost per hour calculator

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, . The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The advantages are it allows for accurate overhead allocation and cost comparisons. The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The advantages are it allows for accurate overhead allocation and cost comparisons.

It also covers drilling, boring, milling, shaping, planning, grinding, and provides formulas for calculating machining times based on factors like tool travel, feed rate, depth of cut, rpm, and cutting speed.

This unit covers the definition and concepts related to Machine Hour Rate (MHR), including the steps for computation and allocation of overheads.

The document discusses machine hour rate, which is a method used to absorb factory overhead costs into production. It defines machine hour rate as the cost of running a machine per hour, calculated by dividing total overhead costs related to a machine by its total working hours.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours.As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.Understanding the importance of CNC machine hour rate calculation is crucial for manufacturers. It helps in accurate cost estimation, determining optimal pricing strategies, evaluating project profitability, and making informed business decisions.

The calculation of the machine hour rate includes depreciation, repairs and maintenance, power, steam, and water use charges, factory rent, rates, and insurance, factory lighting, factory supervision, and machinery insurance.Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability. The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The advantages are it allows for accurate overhead allocation and cost comparisons. The key steps to calculate machine hour rate are: (1) identify machine-related overhead costs, (2) divide total overhead by estimated machine hours to get a rate per hour, (3) rates can vary by machine type. The advantages are it allows for accurate overhead allocation and cost comparisons.

It also covers drilling, boring, milling, shaping, planning, grinding, and provides formulas for calculating machining times based on factors like tool travel, feed rate, depth of cut, rpm, and cutting speed. This unit covers the definition and concepts related to Machine Hour Rate (MHR), including the steps for computation and allocation of overheads.The document discusses machine hour rate, which is a method used to absorb factory overhead costs into production. It defines machine hour rate as the cost of running a machine per hour, calculated by dividing total overhead costs related to a machine by its total working hours.Machine Hours Rate: Formula, Calculation, Problems and Solutions! The machine hour rate is similar to the labour hour rate method and is used where the work is performed primarily on machines. The formula used in computing the rate is: Factory overhead/Machine hours.

As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.

Understanding the importance of CNC machine hour rate calculation is crucial for manufacturers. It helps in accurate cost estimation, determining optimal pricing strategies, evaluating project profitability, and making informed business decisions.

The calculation of the machine hour rate includes depreciation, repairs and maintenance, power, steam, and water use charges, factory rent, rates, and insurance, factory lighting, factory supervision, and machinery insurance.

sm sheet metal

slab electrical boxes

Electrical box extenders are sturdy rings that attach to an existing electrical box, covering the newly installed wall material so it’s protected. Once installed, the extender brings the box edge flush with the finished surface.

cnc machine hour rate calculation ppt|calculating machine cost per hour