cnc machine homemade plans Most homemade CNC routers use a standard woodworking router or trim . Find detail information about welding fabrication job description, duty and skills required for welding fabrication position. What do welding fabricators do? A welder is a skilled craftsman who designs, cuts, welds and shapes metal parts that can .WELDING AND METAL FABRICATION employs a unique hands-on, project-based learning strategy to teach welding skills effectively and keep you motivated. This .

0 · make your own cnc router

1 · make your own cnc mill

2 · make your own cnc machine

3 · homemade cnc machine plans pdf

4 · diy cnc machine for woodworking

5 · build your own cnc mill

6 · build your own cnc machine

7 · build it yourself cnc router

The most important rules while welding thin stainless steel is to use the right welding techniques- that is using the right filler diameter, tungsten electrode, welding parameters along with shielding gas flow rate.

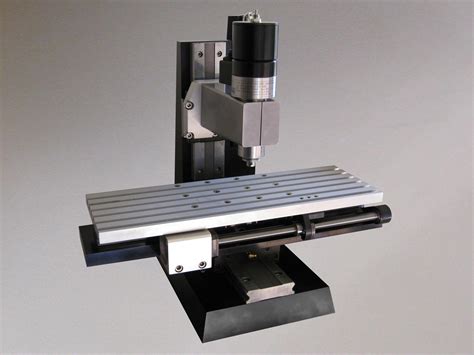

This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this .Most homemade CNC routers use a standard woodworking router or trim .I decided to put my engineering background to the test, and build my own CNC .These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good .

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials.

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Over 1,000 downloads of our DIY CNC plans! I enjoy my home-built DIY CNC Router, so I wrote-up the plans, documented the dimensions and assembled into 72 pages of instructions. It is simple (plywood & aluminum angles), perfect to explore CNC. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.HobbyCNC DIY CNC Router Plans make a great starting point for building an inexpensive 3-Axis CNC router from readily available parts. No fancy drive components or materials. 96 pages total with 49 pages of detailed drawings.Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. Assemble a kitThis Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials.

make your own cnc router

make your own cnc mill

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.

Over 1,000 downloads of our DIY CNC plans! I enjoy my home-built DIY CNC Router, so I wrote-up the plans, documented the dimensions and assembled into 72 pages of instructions. It is simple (plywood & aluminum angles), perfect to explore CNC.

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.HobbyCNC DIY CNC Router Plans make a great starting point for building an inexpensive 3-Axis CNC router from readily available parts. No fancy drive components or materials. 96 pages total with 49 pages of detailed drawings.

make your own cnc machine

homemade cnc machine plans pdf

To understand the causes of welding cracks with brittle fracture, heat affected zone cracking, and hydrogen-induced cracking as solution. These sub-sections identify the three leading causes of welding cracks and offer insights into how they can be prevented.

cnc machine homemade plans|make your own cnc machine