cnc machine ip address mtconnect After setting the IP address, Subnet, and gateway - and the TCP port to 8193, reset the machine's control. You should now be able to ping the IP from the FANUC FOCAS embedded ethernet port pictured above. A K-Factor will typically range between 0 and .5 for standard materials and thicknesses though smaller and larger K-Factors are possible. To help you begin I’ve included a K-Factor Chart below which contains common K-Factor starting points, good for general . See more

0 · mtconnect ip address

1 · mtconnect integration

2 · mtconnect data collection tool

3 · machinemetrics mtconnect

Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By understanding the importance of offsets, operators can minimize material waste, reduce downtime, and produce high-quality parts consistently.

one direction metal lunch box

mtconnect ip address

MTConnect follows the rules of HTTP to fetch and transmit the requested MTConnect command: Haas machine IP address. 8082 fixed TCP port. Machine Data Collection (MDC) lets you use Q and E commands to extract .After setting the IP address, Subnet, and gateway - and the TCP port to 8193, reset the machine's control. You should now be able to ping the IP from the FANUC FOCAS embedded ethernet port pictured above.To configure your Mitsubishi machine with MTconnect, follow these steps: Press the System hard key; Press the System Configure soft key; Scroll left until you see the Comm Settings soft key .

mtconnect integration

Wire Ethernet from your network to the machine and set a static IP. From a desktop, ping the IP address of the machine to confirm that it's connected. In a browser, go to .

Unlock the full potential of your DMG Mori CNC by seamlessly integrating it with Ignition using the Innorobix MTConnect driver. This powerful combination streamlines data flow, enhances operational efficiency, and .Learn how to start collecting data from your Mazak today with the connectivity options outlined below. The most common method of connectivity for Mazak machines is via the MTConnect standard. Mazak actively supports .

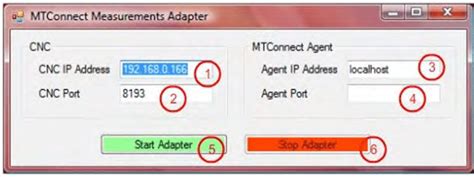

The adapter makes a HAAS VF2 CNC machine MTConnect protocol compliant and enables the machine to communicate with an MTConnect agent. The software has been tested on a HAAS . To get your Okuma CNC machine seamlessly connected with Ignition using the Innorobix MTConnect driver, start by ensuring that your CNC machine is properly configured .

Open Source MTConnect® Agent and Adapter for Haas CNC Machines using Ethernet or RS-232. This supports the basic data collection variables available using setting 143 on Haas . MTConnect follows the rules of HTTP to fetch and transmit the requested MTConnect command: Haas machine IP address. 8082 fixed TCP port. Machine Data Collection (MDC) lets you use Q and E commands to extract data from the control through the Ethernet port or the Wireless Networking option.How to find out if your machine is producing MTConnect data. Wire ethernet from your network to the machine and set a static IP. From a desktop, ping the IP address of the machine to confirm that it's connected. In a browser, go to port 7878 on that machine (Example: 192.168.10.11:7878).After setting the IP address, Subnet, and gateway - and the TCP port to 8193, reset the machine's control. You should now be able to ping the IP from the FANUC FOCAS embedded ethernet port pictured above.

To configure your Mitsubishi machine with MTconnect, follow these steps: Press the System hard key; Press the System Configure soft key; Scroll left until you see the Comm Settings soft key and press it; Enter parameter 1; You will then be able to set your desired IP address, subnet mask and default gateway for MTConnect Wire Ethernet from your network to the machine and set a static IP. From a desktop, ping the IP address of the machine to confirm that it's connected. In a browser, go to port 7878 on that machine (Example: 192.168.10.11:7878) Unlock the full potential of your DMG Mori CNC by seamlessly integrating it with Ignition using the Innorobix MTConnect driver. This powerful combination streamlines data flow, enhances operational efficiency, and enables real-time monitoring.Learn how to start collecting data from your Mazak today with the connectivity options outlined below. The most common method of connectivity for Mazak machines is via the MTConnect standard. Mazak actively supports MTConnect, now offering over 200 machine models that are prepped to accept the MTConnect adapter before they leave the factory.

The adapter makes a HAAS VF2 CNC machine MTConnect protocol compliant and enables the machine to communicate with an MTConnect agent. The software has been tested on a HAAS VF2 machine with the MTConnect cpp agent. To get your Okuma CNC machine seamlessly connected with Ignition using the Innorobix MTConnect driver, start by ensuring that your CNC machine is properly configured to communicate via the MTConnect protocol. This involves setting up the MTConnect agent on your Okuma machine’s controller.Open Source MTConnect® Agent and Adapter for Haas CNC Machines using Ethernet or RS-232. This supports the basic data collection variables available using setting 143 on Haas machines described in the link below: http://diy.haascnc.com/data-collection-using-rs-232-port-0 MTConnect follows the rules of HTTP to fetch and transmit the requested MTConnect command: Haas machine IP address. 8082 fixed TCP port. Machine Data Collection (MDC) lets you use Q and E commands to extract data from the control through the Ethernet port or the Wireless Networking option.

How to find out if your machine is producing MTConnect data. Wire ethernet from your network to the machine and set a static IP. From a desktop, ping the IP address of the machine to confirm that it's connected. In a browser, go to port 7878 on that machine (Example: 192.168.10.11:7878).

After setting the IP address, Subnet, and gateway - and the TCP port to 8193, reset the machine's control. You should now be able to ping the IP from the FANUC FOCAS embedded ethernet port pictured above.To configure your Mitsubishi machine with MTconnect, follow these steps: Press the System hard key; Press the System Configure soft key; Scroll left until you see the Comm Settings soft key and press it; Enter parameter 1; You will then be able to set your desired IP address, subnet mask and default gateway for MTConnect

Wire Ethernet from your network to the machine and set a static IP. From a desktop, ping the IP address of the machine to confirm that it's connected. In a browser, go to port 7878 on that machine (Example: 192.168.10.11:7878) Unlock the full potential of your DMG Mori CNC by seamlessly integrating it with Ignition using the Innorobix MTConnect driver. This powerful combination streamlines data flow, enhances operational efficiency, and enables real-time monitoring.Learn how to start collecting data from your Mazak today with the connectivity options outlined below. The most common method of connectivity for Mazak machines is via the MTConnect standard. Mazak actively supports MTConnect, now offering over 200 machine models that are prepped to accept the MTConnect adapter before they leave the factory.The adapter makes a HAAS VF2 CNC machine MTConnect protocol compliant and enables the machine to communicate with an MTConnect agent. The software has been tested on a HAAS VF2 machine with the MTConnect cpp agent.

To get your Okuma CNC machine seamlessly connected with Ignition using the Innorobix MTConnect driver, start by ensuring that your CNC machine is properly configured to communicate via the MTConnect protocol. This involves setting up the MTConnect agent on your Okuma machine’s controller.

mtconnect data collection tool

machinemetrics mtconnect

one control pedalboard junction box

one control pedalboard junction box

Load cell trimming is sometimes called load cell summing because it involves tying or summing multiple load cell output signals together. This happens in a junction box, also known as a summing box, which sends one system signal to the indicator.

cnc machine ip address mtconnect|mtconnect integration