sheet metal bending fabrication Six Star Sheet Metal Fabrication- Sheet Cutting & Bending Works.

[email protected]. Call Us On: 7902625618 Opening Hours: 09:00 AM to 05:00 PM . Body bending of jewellery lockers,SS or aluminium water . Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations.

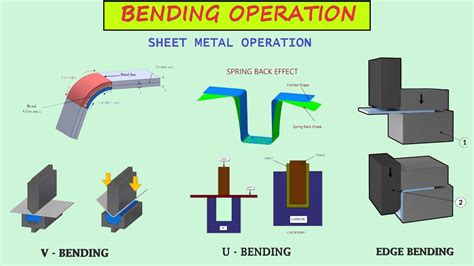

0 · types of sheet metal bending

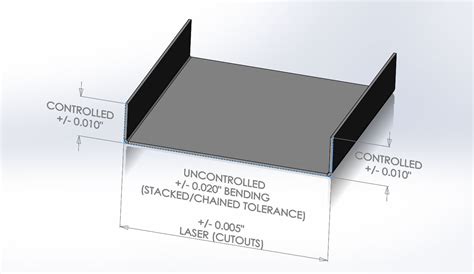

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending basics

5 · bending sheet metal by hand

6 · bending sheet metal at home

7 · bending galvanized sheet metal

Using state-of-the-art technical weaving equipment, we create highly specialized architectural metal mesh systems in close cooperation with our clients to achieve the best results. Contact .

Bending is one of the most common sheet metal fabrication techniques. With bending, metal is deformed with specialist machinery into an angular shape. The bending of sheet metal allows a wide variety of part geometries to be produced and is particularly useful when performed .Six Star Sheet Metal Fabrication- Sheet Cutting & Bending Works. [email protected]. Call Us On: 7902625618 Opening Hours: 09:00 AM to 05:00 PM . Body bending of jewellery lockers,SS or aluminium water .Our Winston-Salem team combines cutting-edge technology with years of expertise to provide precise and efficient solutions for all your metal fabrication needs. Explore Our Sheet Metal Punching & Cutting Services. Sheet Metal Bending. There are a variety of sheet metal bending techniques that can be used to accomplish the desired result for .Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications, ensuring high-quality custom sheet metal parts with precision .

In sheet metal bending calculations, the impact of different material types on the bending factor is significant and multifaceted, influencing the accuracy, quality, and efficiency of the bending process. . This article demystifies the crucial role of fabrication holes in sheet metal bending. You'll learn how these holes.Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . When bending sheet metal, it’s impossible to create a completely sharp corner. There will always be a slight curve which is .Experience unparalleled precision and innovation with TAIWA, your trusted custom sheet metal fabricator. From laser cutting to metal bending and forming, our state-of-the-art Japanese equipment ensures impeccable quality. We offer a full suite of services, including prototyping, large-scale fabrication, welding, and assembly, catering to diverse project needs.When it comes to bending metal whether it's bar, sheet, plate, or tubing we can probably bend it. . Axiom Race Fabrication. 360 Stan Drive, Suite B Melbourne FL. 32904. Monday - Friday 9:00am - 6:00pm Saturday - 12:00pm - 6:00pm. 321-914-4705 • Contact us now! [email protected]. Facebook .

V-bending is a form of sheet metal fabrication that uses a V-shaped die to bend the material into a curved shape. This tool can be used to create many different kinds of bends, including 90-degree angles, curves, and more. In sheet metal bending, you work a flat metal piece by applying a force that deforms it along a straight axis. The result is an angular change in shape allowing you to form curved and angled parts. . Changing metal sheet thickness results in inconsistent bend angles. Applications. General fabrication requiring multiple bends with different .Curved sheet metals. Image credit: https://kdmfab.com Curved sheet metal is another method of sheet metal bending used to create more complex curved shapes and designs. It involves creating a curved bend in a sheet metal using a press brake or rollers. The press brake uses a die and punch to create the desired bend, while the rollers use a series of rollers to shape the metal. http://www.shortrunpro.com - This installation shows the process of bending metal in our metal fabrication facility. See the use of manual and automated pr.

CNC sheet metal bending is one of the most underrated processes available for sheet metal part production. With bending, it’s possible to produce a wide variety of part geometries without tooling, at fast lead times, with high levels of repeatability and through automated processes. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and KnightBest Metal Fabricators in Bend, OR - JC Precision Welding, Advanced Northwest Welding, Bend Heating & Sheet Metal, CLS Fabrication, Jon Small Welding, J Bar Metal Fabrication, Simply Fabricated, SC Welds, All Weld, Bend Machine . Bend Heating & Sheet Metal. 4.2 (17 reviews) Heating & Air Conditioning/HVAC Metal Fabricators.Manufacturer of Sheet Metal Fabrication Service - CNC Bending Services, Sheet Metal Fabrication Services, Sheet Metal Bending and Shearing Service and Sheet Metal Components Job Work offered by Exilon Industries, Greater .Top 10 Best Sheet Metal Fabrication in San Jose, CA - November 2024 - Yelp - Fusion Welding, A & J Precision Sheetmetal., Odie Sheet Metal, Custom Metal Manufacturing Company, Kc Sheetmetal, Acosta Sheet Metal Mfg, Industrial Metal Service, Nick's Machining, Superior Roof Metals, Vander-Bend Precision Sheetmetal

With two expansive sheet metal fabrication factories and a dedicated team of over 90 specialists, we at Shengen stand at the forefront of the industry. Our in-house expertise allows us to handle any project, no matter the size or complexity.Sheet metal forming techniques include bending, stamping, stretching, rolling, and deep drawing. . Sheet metal fabrication’s vast construction applications are due to the durability, strength, high weather resistance, manufacturability, versatility, aesthetic qualities, and other beneficial properties of various sheet metals, including . Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake.. In this article, we provide a comprehensive guide on sheet metal bump bending with details on the suitable metals you .

We offer premium quality sheet metal fabrication services using a wide variety of state-of-the-art equipment. . Sheet metal bending to 4m. Welding. Welding joins two metal parts by heating them together and pushing them to connect. This could entail welding two separate components together to form a more significant component or assembling .Our online sheet metal fabrication service can ship custom sheet metal parts and assemblies in as fast as 1 day. Request a quote today to get started. . Forming/bending (≤12 bends) Hardware insertion (extensive PEM® library) Tapping/countersinks; Material thicknesses: ≤0.125 in. (≤3.175mm) Brackets; Covers; Panels;Welcome to Laser Technic®, Noida, your one-stop destination for high-quality custom sheet metal fabricated parts and assemblies. We manufacture panel enclosures, electronic enclosures, cabinets, battery boxes, kiosks, telecom tower/antenna clamps, and industrial & IT racks. Besides metal fabrication, we also offer metal laser cutting and CNC bending services. Our team of .

Your go-to welding Bend Oregon company! For inquiries call (541) 325-8543. Sheet metal fabrication involves cutting, bending, and shaping metal sheets to create components and structures for diverse applications. . Sheet metal bending is the bending of sheet metal into the desired shape and Angle according to the requirements of the drawing. The commonly used bending equipment is the bending machine. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.

shark sd120 cnc machine

types of sheet metal bending

sheet metal bending standards

sheet metal bending near me

Download our IP66 PVC Junction Box here. Contact us today at [email protected]. Wanco Electric is the market leader in electrical fittings for electrical construction materials.

sheet metal bending fabrication|sheet metal bending guidelines