sheet metal bending calculation software Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and . Investors Include: Founders Fund, Andreessen Horowitz, Caffeinated Capital Hadrian is an automated precision manufacturing company focused on revolutionizing aerospace and defense manufacturing. The startup .

0 · software for sheet metal fabrication

1 · sheet metal flat layout software

2 · sheet metal bending software free

3 · metal fabrication software free

4 · metal fabrication blueprint software free

5 · free sheet metal layout software

6 · free sheet metal design software

7 · cad software for fabricating steel

The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc .

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and .A sheet metal bend calculator is a tool that helps you calculate important parameters required in the bending of sheet metal. The calculator uses these parameters to determine the flat length . Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. Use SendCutSend’s bending calculator to input your desired material .

Real-World, K-Factor Calculation. SigmaUNFOLD empowers you to recognize sheet metal bend features in a 3D body and flatten the part using accurate K-factor based calculations, which ensures a realistic, real-world representation .

Easily calculate the K-Factor to be used in your 3D design software. Reverse engineer the K-Factor from your own shop validated data. Find out how much tonnage will be required for a . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .

what size circular saw is needed for sheet metal cutting

With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .

Bend-O-Matic is Sheet Metal Bending software to determine Initial Strip Width, V-Block Sizes, Maximum Force and Minimum Overhang used in sheet metal industries.OutShape Explainer - EN - Reupload. Universal DXF files within minutes. When bending metal, there will be a change in the materials. For accurate flat patterns, OutShape is the perfect solution to process more drawings while saving . Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. . 10 .

SigmaUNFOLD Industry-Leading Unfolding Technology Working for You Real-World, K-Factor Calculation. SigmaUNFOLD empowers you to recognize sheet metal bend features in a 3D body and flatten the part using accurate K-factor .

The software designers at Bend-Tech understand sheet metal and know what is needed to make quick work of designs. There are many specific features to make the design work faster such as; path text, bridging, slots for bend relief, void .The software can automatically develop the bending schedule and the marker diagram for the bent component. Application Areas: PLUS Bend is useful for Cabinet Manufacturers, Manufacturing of Industrial Enclosures, HVAC and Door Manufacturers and a range of industries in Sheet Metal Bending. PLUS BEND : Bend Allowance Calculation Software . 3D View:Precision Sheet Metal Fabrication Machinery | RAS Systems / Products / Software / Bending 4.0. . The Bendex software imports the file format and programs the part with a single mouse click. If programming took 10 minutes before, the Bendex Office software creates a program in less than one minute, and in addition visualizes the bending .Use the TRUMPF BendGuide to calculate key bending parameters quickly and simply: Press force calculation; Press force table; Nesting height; Flange length; Die width; Open-height check; Inner radius; Sheet thickness conversion; Tool weight calculation; Sheet metal weight calculation

The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal. However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table.The software designers at Bend-Tech understand sheet metal and know what is needed to make quick work of designs. There are many specific features to make the design work faster such as; path text, bridging, slots for bend relief, void slots for bend zones and manual bending, corner notches, and specific hole shapes including dimple die, and ellipse.

The sheet metal blank size is determined by considering factors like part dimensions, material thickness, bend allowance, stretch allowance, bend radius, minimum bend distance, material properties, K-factor, drawing ratio, setback, tooling, tolerances, part complexity, and material utilization efficiency. Accurate calculations ensure efficient use of material and . Bending of sheet metal is one of the essential processes carried out in numerous industries, and it demands a lot of attention in terms of calculations and other aspects to obtain the desired outcome correctly. The reader has to appreciate that one of the most critical parameters to deal with is the bend radius, which physically applies itself . While bending produced metal parts, it results in wrong size of bent edges. How to calculate K-Factor in Inventor for Sheet Metal part? What is Bend Allowance? More material is stretch when is compresses, which lead in part being longer after bending The bending allowance calculator provided below simplifies the process of calculating the bending allowance value, which is crucial for accurate sheet metal fabrication. Bend allowance is the length of the neutral axis between the bend lines, which helps in determining the correct blank size for a bent part.

Calculation of sheet metal unfolding through 3D modeling software by K-Factor method and its application range. The manual drawing process is low in efficiency. By using a three-dimensional modeling software and the K-factor method, the efficiency of sheet metal unfolding calculation is significantly improved. To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves creating a controlled deformation to form a . These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD .

what size screws in metal electrical boxes use

Press brake software is a tool used to calculate and simulate metal sheet bending, which provides a comprehensive solution for sheet metal bending. It controls and guides the press brake machine by generating programmable .

The Standard Edition software includes the Large Radius Module already. Bend Tech SE Triple Bundle: This is Bend Tech SE with YOUR CHOICE OF 3 modules. These include Sheet Metal (designer), Sheet Metal Templates, Roll .

Basically you want to remove the material at the edge of the bend. We provide a simple calculation you can do to determine a safe minimum size for your bend relief. . Designing bend reliefs manually gives you more freedom but is more difficult to calculate, or if you’re using software with sheet metal tools built in, you can have it add the .The goal of SheetMetalWorks is to ensure a streamlined sheet metal process chain. This includes improved commands for sheet metal design, tools that guarantee a production-ready flat pattern, and multiple export formats for CAM and CNC.At the core of SheetMetalWorks is a powerful unfolder that considers not only the material and sheet thickness but also your laser, punching, .Revcad Ltd product and services as the developers of sheet metal unfold software. S E C T I O N S. Sheet Lightning -Sheet Metal Pattern Development Software. Sheet Metal Design and Unfolding Software for Tees, Bends, . lobster-back or segmented bend and very unusual or complex one-off designs. All pieces can have center line offset and .

what size junction box

Sheet Bending Calculator latest update: November 5, 2024 . (it's extremely likely that this software program is clean) . Keywords- fabrication, bending, sheet metal bending, plate bending .If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. I normally would generate both a flat pattern as well as a folded views of the model, but I feel that it is way overkill to dimension every tiny little indent and notch and cut.Layer 2Dref is the same, with auxiliary lines, to help bending or folding the sheet metal patterns into finished metal entities: 2D MESH; color red Layer txt is for the texts, as name of the pattern, pattern calculation date, user parameter input, user settings at that moment; and annotations of number of flat pieces and its thickness

The variables in this formula include: S: Sheet thickness; r: Inner radius during bending; K: Width of the horizontal projection of the bending deformation zone; From the derivation process, it is essential to meet two additional conditions when using formulas (2) or (3) to calculate bending force: the width-to-thickness ratio (V/S) must equal 9, and the radius-to-width ratio must equal .

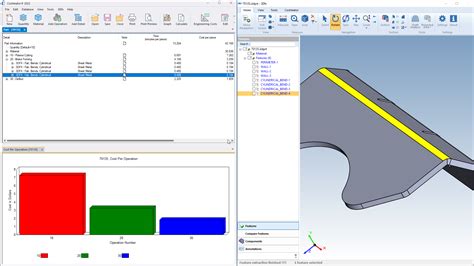

Curved sheet metals. Image credit: https://kdmfab.com Curved sheet metal is another method of sheet metal bending used to create more complex curved shapes and designs. It involves creating a curved bend in a sheet metal using a press brake or rollers. The press brake uses a die and punch to create the desired bend, while the rollers use a series of rollers to shape the metal. Comments. Optimate cloud-based software, as an app or CAD plug-in, now features integrated cost calculation where job shops and OEMs that produce and design sheet metal products need only a single click to calculate the costs of their parts. Comments. Optimate cloud-based software, as an app or CAD plug-in, now features integrated cost calculation where job shops and OEMs that produce and design sheet metal products need only a single click to calculate the costs of their parts.

software for sheet metal fabrication

The DT-1 is a compact, high-speed drill and tap machine with full milling capabilities. A powerful BT30 taper inline direct-drive spindle provides 10,000 rpm, and allows high-speed rigid tapping. A high-speed, 20-pocket tool changer swaps tools quickly, while 2400 ipm rapids and high acceleration rates shorten cycle times and reduce non-cutting .

sheet metal bending calculation software|sheet metal bending software free