caulking for around electrical boxes The number one rule is to keep the material you use from getting into the box too much. Electrical boxes are rated for volume and that volume determines how many wires and splices can fit. You also don’t want the foam . Computer numerical control (CNC) machines shape material using pre-programmed routines. They can create parts efficiently and at a high degree of precision. As a .

0 · sealing outdoor electrical box

1 · sealing around electrical cables

2 · sealant for electrical boxes

3 · insulating around outlets

4 · insulated outlet covers

5 · insulate electrical outlets

6 · how to seal electrical outlets

7 · filling holes around electrical wires

For any inquiries and collaboration requests, please use the contact form .

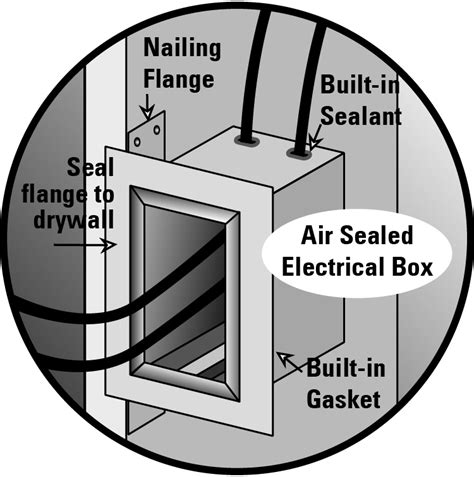

The number one rule is to keep the material you use from getting into the box too much. Electrical boxes are rated for volume and that volume determines how many wires and splices can fit. You also don’t want the foam .For wall-mounted electrical boxes, caulk all openings in the box (including around the wire penetrations) and seal around the box where it meets the drywall. Seal wiring gaps and holes (e.g., for security system wiring, television and internet . First thing is they plunge the Roto-zip into the box looking for the outside of it while ripping your wires to spreads. Then they over cut the hole.Seal around installed wiring using caulk or canned spray foam. For ceiling-mounted electrical boxes, install the electrical box in the ceiling drywall, then caulk around the base and caulk all holes in the box with fire-retardant caulk.

This blog provides guidance on the best practices for air-sealing electrical boxes, outlining key tips and recommending reliable products suited for the job. With the right materials and . Outdoor receptacle boxes aren't intended to be sealed. Yes, that's right: the standard outdoor/weatherproof electrical enclosures in use in the US are not intended to be sealed against water ingress. In fact, the NEC contains an . Air sealing the holes inside an electrical box: silicone caulk, every time. Air sealing the gap around an electrical box: silicone caulk for gaps below 1/4″, or in high temps. Otherwise, spray foam.

Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. The process of insulating around electrical boxes involves a few simple steps including measuring the distance between the electrical box and the drywall, cutting and fitting the insulation, and sealing the insulation in place . The number one rule is to keep the material you use from getting into the box too much. Electrical boxes are rated for volume and that volume determines how many wires and splices can fit. You also don’t want the foam sealing up .

sealing outdoor electrical box

For wall-mounted electrical boxes, caulk all openings in the box (including around the wire penetrations) and seal around the box where it meets the drywall. Seal wiring gaps and holes (e.g., for security system wiring, television and internet cables, exterior outlets, and switches) through exterior walls, floors, or ceilings, with caulk . First thing is they plunge the Roto-zip into the box looking for the outside of it while ripping your wires to spreads. Then they over cut the hole. All you need is a caulk gun, caulk and aerosol foam. Here’s how to do it. Gaps around ceiling boxes must be sealed with an intumescent fireblocking caulk or foam. Ordinary spray foam burns too quickly, opening the gap and creating a chimney effect that feeds the fire.

Seal around installed wiring using caulk or canned spray foam. For ceiling-mounted electrical boxes, install the electrical box in the ceiling drywall, then caulk around the base and caulk all holes in the box with fire-retardant caulk.This blog provides guidance on the best practices for air-sealing electrical boxes, outlining key tips and recommending reliable products suited for the job. With the right materials and techniques, you can effectively air-seal electrical boxes and minimize air leakage.

metal beam bracket

Outdoor receptacle boxes aren't intended to be sealed. Yes, that's right: the standard outdoor/weatherproof electrical enclosures in use in the US are not intended to be sealed against water ingress. In fact, the NEC contains an explicit allowance (in 314.15) for drain holes in the bottom of boxes. Why is this? Air sealing the holes inside an electrical box: silicone caulk, every time. Air sealing the gap around an electrical box: silicone caulk for gaps below 1/4″, or in high temps. Otherwise, spray foam.Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations. The process of insulating around electrical boxes involves a few simple steps including measuring the distance between the electrical box and the drywall, cutting and fitting the insulation, and sealing the insulation in place with a vapor barrier.

The number one rule is to keep the material you use from getting into the box too much. Electrical boxes are rated for volume and that volume determines how many wires and splices can fit. You also don’t want the foam sealing up .For wall-mounted electrical boxes, caulk all openings in the box (including around the wire penetrations) and seal around the box where it meets the drywall. Seal wiring gaps and holes (e.g., for security system wiring, television and internet cables, exterior outlets, and switches) through exterior walls, floors, or ceilings, with caulk . First thing is they plunge the Roto-zip into the box looking for the outside of it while ripping your wires to spreads. Then they over cut the hole.

All you need is a caulk gun, caulk and aerosol foam. Here’s how to do it. Gaps around ceiling boxes must be sealed with an intumescent fireblocking caulk or foam. Ordinary spray foam burns too quickly, opening the gap and creating a chimney effect that feeds the fire.

Seal around installed wiring using caulk or canned spray foam. For ceiling-mounted electrical boxes, install the electrical box in the ceiling drywall, then caulk around the base and caulk all holes in the box with fire-retardant caulk.This blog provides guidance on the best practices for air-sealing electrical boxes, outlining key tips and recommending reliable products suited for the job. With the right materials and techniques, you can effectively air-seal electrical boxes and minimize air leakage. Outdoor receptacle boxes aren't intended to be sealed. Yes, that's right: the standard outdoor/weatherproof electrical enclosures in use in the US are not intended to be sealed against water ingress. In fact, the NEC contains an explicit allowance (in 314.15) for drain holes in the bottom of boxes. Why is this? Air sealing the holes inside an electrical box: silicone caulk, every time. Air sealing the gap around an electrical box: silicone caulk for gaps below 1/4″, or in high temps. Otherwise, spray foam.

Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations.

sealing around electrical cables

metal barn next to house conected by breezeway

metal barn house plans texas

The ceiling fan box is the electrical box that is attached to a ceiling joist with wood screws. These special 'fan-rated electrical boxes' will typically hold 50-70 pounds but certain ones like L-shaped brackets, bar brackets, and .

caulking for around electrical boxes|filling holes around electrical wires