sheet metal inspection equipment Perform sheet metal inspections with our award winning Planar 2D Inspection . That's usually referred to as an end-swell, which is basically a small piece of metal that's kept on ice which is applied to any area of a fighter's face that is swelling or bruising. By decreasing blood flow to a specific area of a fighter's face, cornermen can help to reduce swelling, particularly around the eyes.

0 · surface inspection system for steel

1 · surface finish inspection equipment

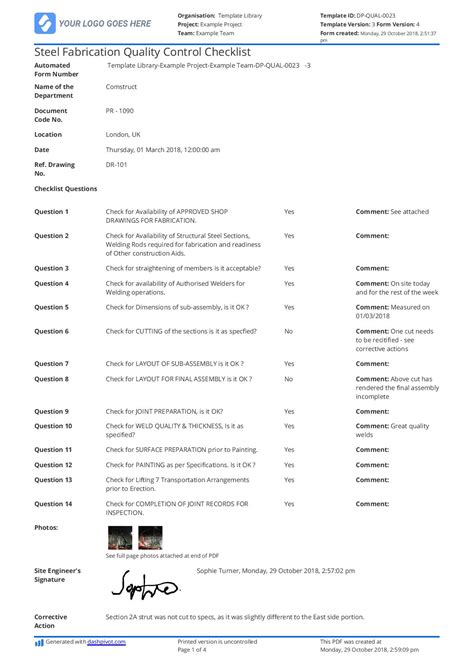

2 · sheet metal quality checklist

3 · sheet metal inspection checklist

4 · scanning surface inspection system

5 · inspection lights for surface defects

6 · freescan combo 3d scanner

7 · automated optical surface quality inspection

Roof flashing is a thin piece of sheet metal typically made from galvanized steel, aluminum, or copper that’s used to direct water runoff away from susceptible areas and seal the roof covering at all edges.

Sheet Metal Inspection. A sheet metal inspection and reverse engineering solution using the InspecVision Planar2D - the worlds fastest 2D measurement system.Sheet Metal Inspection; Electrical Laminations Inspection; Gasket and .Perform sheet metal inspections with our award winning Planar 2D Inspection .Precision Measurement Machines for Smart Manufacturing. We design, manufacture .

Precision Measurement Machines for Smart Manufacturing. We design, manufacture and sell vision systems for automated inspection and reverse engineering. Specialists in Sheet Metal .Coordinate measuring machines (CMMs) Whether you are looking for an entry-level model or already have experience with coordinate measurement systems and are now looking to improve quality assurance or increase inspection .

Virtek LaserQC® dramatically increases throughput in precision sheet metal, tubing, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article .SmartView Surface Inspection is industry-leading technology for real-time surface defect detection ideal for aluminum, steel, paper, plastics and nonwovens industries.Perform sheet metal inspections with our award winning Planar 2D Inspection Machine, the fastest and most automated 2D inspection system in the world.Being an industry leader in the custom fabrication, finishing of sheet metal products and product inspection equipment. . This means we can provide high-quality, quick-turn parts & equipment at competitive prices. Our versatility .

CMM controller upgrades and retrofits ensure your equipment keeps pace with the latest standards Explore Range. Gantry CMMs. Gantry CMMs provide accurate large-volume part inspection on the production floor, in production .sheet metal parts are often used in the most demanding applications such as aerospace or automotive or in very large production runs, all of which require inspection. Sheet Metal Inspection Difficulties When producing small production runs for more mundane applications, a typical sheet metal part is often painted, formed and welded.FabriVISION maximizes the throughput of your turret and laser by eliminating delays in the inspection process. FVL-HD-3030, FVL-HD-4848, Plus FabriVISION 3Di Laser with 3D intelligence technology . and other rigid parts. If you’re a quality-conscious sheet metal fabricator who strives to stay ahead of your competition, FabriVISION can .With advanced equipment like the Keyence WM-3000 CMM and Virtek 3D Laser Scanning Machine, our skilled team is able to provide comprehensive validation services. . Whether you need engineering support, sheet metal fabrication, or inspection services, we have you covered. Contact our team to get started. OUR Certifications. ADVANTAGE METAL .

Looking for highly precise measurement equipment for sheet metal? Get expert advice from The Sempre Group by calling +44(0)01452 632 712. About Us. . Bore Inspection - Novacam Boreinspect™ . Cut down on scrap and speed up the measurement of sheet metal with our measurement systems that can quickly correct machines and inspect multiple parts.

surface inspection system for steel

surface finish inspection equipment

Planar Quality Control Machines / 2D Inspection Machine, SurfScan 2.5D Add-on, and Opti-Scan 3D Add-on. Contact Milam Machinery today to order.Vertec offers custom sheet metal fabrication and precision machining services nation-wide for any custom metal project. Vertec in Colorado Springs. . Quality Codes; Contact; Engineering. Finishing. Inspection. Machining. Sheet Metal. Gallery. Video. Inspection Equipment List. 2 Brown and Sharpe Global Performance programmable CMMs with .0003 .

Our sheet metal inspection ensures precision and quality. Elevate your projects with our comprehensive quality assurance. Get your free quote and learn more! . Our team stands at the forefront of innovation, utilizing cutting-edge inspection methods alongside state-of-the-art equipment and technology. This commitment allows us to meticulously .

China Sheet Metal Work: A Growing Industry Sheet metal work is the process of manipulating thin metal sheets to create various products. . Global X-ray Food Inspection Equipment Market 2018- Packaged Product Inspection Equipment, Bulk Product Inspection Equipment The global . Learn More. China Sheet Metal Manufacturers and Suppliers: Honesty .Ketec Precision Tooling Inc. is a professional manufacturer of CNC punch press tooling, stamping, punches, bending, and automobile press mold.Caliper, pin gauge, thread gauge, height gauge, and project specific inspection equipment are used throughout our processes. All of Dalsin’s CMM’s, scanners, and Raytek measuring tables offer full documentation for reporting and data collection purposes. . Dalsin leads the market in high-value contract manufacturing of precision sheet .

Find manufacturers and fabricators of Duct Inspection Equipment in the Sheet metal industry that includes a variety of HVAC sheet metal products and tools as well as air conditioners.Virtek LaserQC® dramatically increases throughput in precision sheet metal, tubing, precision foam, leather, aerospace and gasket fabrication. The system is designed for first article inspection, quality reporting (spc, iso, lean, etc.), reverse engineering and automatic formed measurement. Industries Sheet Metal & GasketsTUBE LASERS Extremely Competitive Prices View >> From 3/4" diameter to 20" diameter SHEET & PLATE LASER View >> Starting at ,000 / From 4'x4' to 13'x80', Up to 30 kW QUALITY CONTROL MACHINES View >> 2-D, 2.5-D, and 3-D Sheet Metal Part Inspection Inspection Machines

CMM Inspection. The most common inspection equipment used today is the CMM or (Coordinate Measuring Machine). Our machines are annually calibrated and are accurate to 5 microns (0.005mm) (0.0002”) they are D.C.C. or (Direct .Inspection View Welding View Assembly View Request a quote now . Sheet Metal Our fully tooled sheet metal department can cut, punch and form parts to your specifications. . Our fully tooled sheet metal department can cut, punch .QC Equipment Romer CMM Arm Virtec Laser inspection machine for file to part comparison and reverse engineering Gauge blocks, hand tools, etc. all covered by an active calibration program . General Shop Equipment ¼” X 10’ Shear 10 ga. X 27” Shear Cincinnati Gilbert Radial Drill 2 - Flexarm Drill / Tap Arms

The Planar inspection system—the world’s fastest automated 2D inspection system—requires zero setup, features single-click inspection, and records up to 40 million points in under 0.1 seconds. . Manufacturers and sheet metal fabricators—especially those who operate X/Y CNC, laser, plasma, punch, water jet cutting, and forming machines .Over the past 50 years, our CMMs and metrology equipment have been used in nearly every field of application possible, including the aerospace, automotive and medical industries. Industry. . Sheet Metal Inspection; Powertrain Components; Turbine Blade Inspection; Scanning / Reverse Engineering; Mold Tooling; Industry. Medical.Sheet Metal Inspection; Electrical Laminations Inspection; Gasket and Seal Inspection; O-Ring Inspection; In Line Inspection; Convert Paper Drawings to CAD; Castings; Reverse Engineering; Quality Control; Rapid Prototyping; Get in touch +44 (0) 2890 844 012 [email protected]. Managed Services.The automotive industry demands precision pattern-matching and alignment solutions for automotive metal stamped components including frame pieces, safety equipment, motors, and engines. Automation systems rely on machine vision to calculate accurate coordinates, which robots use to pick and align sheet metal blanks with tool and die surfaces.

The press shop at BMW‘s Dingolfing plant relies on optical metrology systems including automation and standardization for inspection of shee t metal components. Here, 3D coordinate measuring technology from GOM sets completely new standards, offering high time-saving potential since sensor, automati.

Technical standards and manuals developed by SMACNA members have worldwide acceptance by the construction and code community, as well as local and national government agencies. ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and .3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and inspect complex parts, assemblies and tooling to a higher level of accuracy and in a shorter period of time than with other methods. Instead of collectingContinue reading. Figure 1: An operator uses the FaroArm’s contact probe to inspect a sheet metal product for accuracy. India is fast rising as a manufacturing powerhouse. With Prime Minister Modi’s “Make in India” programme, the manufacturing industry in India is set to become the fifth-largest in the world by 2020, worth an expected US trillion by 2025. Sometimes, they even use sheet metal fabrication hand tools, depending on the project. Familiarizing yourself with the available tools and their functions can significantly improve your skills and outcomes in sheet metal work. Each piece of equipment has a function and use in fabrication, from bending machines to surface finish tools.

sheet metal quality checklist

surface mount junction box with key

Machine zero, also known as the origin point or reference point, serves as the baseline for all CNC operations. It is the starting position from which all the coordinates and tool movements .

sheet metal inspection equipment|surface finish inspection equipment