2 gauge in junction box grounding What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes . In 1949, Parsons, along with his employee Frank Stulen, developed a system that utilized punched cards to control the movements of machine tools. This system laid the foundation for what would later become known as .

0 · terminal junction box wiring guide

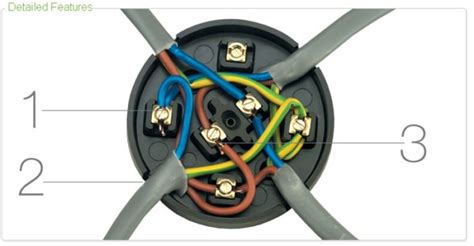

1 · junction box wiring identification

2 · junction box wiring guidelines

3 · junction box grounding requirements

4 · grounding wire for metal box

5 · grounding screws for metal boxes

6 · grounding outlet into metal box

7 · ground wire in electrical box

Explore the basics of cutting, bending, and welding all in one condensed interactive format. Using FMA’s textbook "Metal Fabrication: A Practical Guide", the workshop follows the full process of metal fabrication. Training is augmented by extensive shop .

terminal junction box wiring guide

Upgrading ungrounded two-prong outlets to modern grounded receptacles is an important safety measure for any home. That third prong . What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes . Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be .In a metal junction box, I found that two out of three cables had worn or damaged insulation. I updated these two sections with 12/2 Romex. When reconnecting everything, should I attach .

2) Grounding conductors smaller than #6 must be run in conduit or armored cable. For grounding a service panel to a “made electrode” such as a grounding rod, 6-gauge copper is typically adequate. For runs of over 20 ft. from service . With an approved EMT metal conduit (not a stone cairn), you can use the conduit as the ground path if you ground to the top metal box. Regardless, terminate the Romex at the top box and run actual marked THHN . The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance branch circuit. In this instance I kept the equipment grounds from the 2 circuits separate.

Metal junction boxes provide a reliable and sturdy way to ground electrical wiring. These boxes can help protect your home from potentially dangerous electrical shocks when properly grounded. There are a few different ways to ground a metal junction box. Upgrading ungrounded two-prong outlets to modern grounded receptacles is an important safety measure for any home. That third prong provides a path for excess electrical current, minimizing the risk of shock and fire. We’ll explore three different ways to ground two-prong outlets and bring your home’s electrical system up to code. What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes have a 10-32 tapped hole to accept a ground screw but almost all of the pre-built pigtails that . Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference?

In a metal junction box, I found that two out of three cables had worn or damaged insulation. I updated these two sections with 12/2 Romex. When reconnecting everything, should I attach the ground wires to the grounding screw or simply join them with a wire nut?2) Grounding conductors smaller than #6 must be run in conduit or armored cable. For grounding a service panel to a “made electrode” such as a grounding rod, 6-gauge copper is typically adequate. For runs of over 20 ft. from service panel to grounding rods, increase to 4-gauge wire. With an approved EMT metal conduit (not a stone cairn), you can use the conduit as the ground path if you ground to the top metal box. Regardless, terminate the Romex at the top box and run actual marked THHN wire down the pipe.

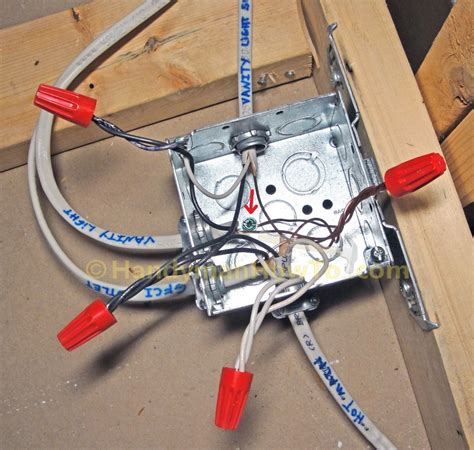

Junction boxes must be grounded to provide a path for fault current to return to the source and to prevent electrical shock. Using an approved grounding method, you must connect the grounding conductor to the junction box. After connecting the wires, secure them neatly inside the junction box. Additionally, if the box is made of metal, ensure proper grounding by connecting a ground wire to the grounding screw provided in the box. This step is crucial for safety and compliance.

The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance branch circuit. In this instance I kept the equipment grounds from the 2 circuits separate.

Metal junction boxes provide a reliable and sturdy way to ground electrical wiring. These boxes can help protect your home from potentially dangerous electrical shocks when properly grounded. There are a few different ways to ground a metal junction box.

Upgrading ungrounded two-prong outlets to modern grounded receptacles is an important safety measure for any home. That third prong provides a path for excess electrical current, minimizing the risk of shock and fire. We’ll explore three different ways to ground two-prong outlets and bring your home’s electrical system up to code.

What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes have a 10-32 tapped hole to accept a ground screw but almost all of the pre-built pigtails that . Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference? In a metal junction box, I found that two out of three cables had worn or damaged insulation. I updated these two sections with 12/2 Romex. When reconnecting everything, should I attach the ground wires to the grounding screw or simply join them with a wire nut?2) Grounding conductors smaller than #6 must be run in conduit or armored cable. For grounding a service panel to a “made electrode” such as a grounding rod, 6-gauge copper is typically adequate. For runs of over 20 ft. from service panel to grounding rods, increase to 4-gauge wire.

With an approved EMT metal conduit (not a stone cairn), you can use the conduit as the ground path if you ground to the top metal box. Regardless, terminate the Romex at the top box and run actual marked THHN wire down the pipe.

junction box wiring identification

Junction boxes must be grounded to provide a path for fault current to return to the source and to prevent electrical shock. Using an approved grounding method, you must connect the grounding conductor to the junction box.

red seal sheet metal

Carlon produces a full line of weatherproof electrical products for safe installation .

2 gauge in junction box grounding|grounding wire for metal box