beading process in sheet metal work Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process. Moog LCA bushing is steel jacketed correct? if you press a steel jacket bushing you don't use any lube between the jacket and arm. I would not use any lube in the center of a rubber bush, but be sure you time your bushings when your done.

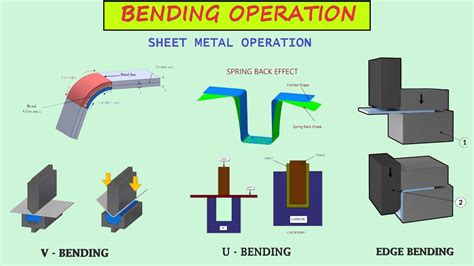

0 · types of sheet metal bending

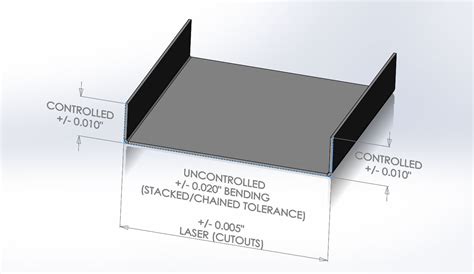

1 · sheet metal bending standards

2 · sheet metal bending dies

3 · maximum thickness sheet metal bending

4 · bending tool for sheet metal

5 · bending sheet metal 90 degrees

6 · beading process in sheet metal

7 · beading machine for sheet metal

Surface finishes refer to the processes applied to the surface of CNC-machined parts to enhance their appearance, protect against corrosion, reduce friction, or meet aesthetic or functional requirements.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be. Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The .Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, .

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s . The design of drawbeads is discussed in depth, with treatment of different bead cross sections, bead end shapes, and bead materials. International standards and practices are included.Bending is a most common sheet metal forming operation. Many products like automobile components and its body, home appliance, paper clip, metal doors etc. are shaped by bending process. Before discussing about bending process .

In this blog, we explore the process of sheet metal fabrication and the various techniques involved. This includes heating, bending, notching, shrinking, and beading. We’ll delve into each step to give you a . Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE "

Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?” The design of drawbeads is discussed in depth, with treatment of different bead cross sections, bead end shapes, and bead materials. International standards and practices are included.Bending is a most common sheet metal forming operation. Many products like automobile components and its body, home appliance, paper clip, metal doors etc. are shaped by bending process. Before discussing about bending process and its types, first you should learn about basic terminologies used in bending.

In this blog, we explore the process of sheet metal fabrication and the various techniques involved. This includes heating, bending, notching, shrinking, and beading. We’ll delve into each step to give you a comprehensive understanding of how these methods contribute to successful sheet metal work. Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be.

We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE " Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?” The design of drawbeads is discussed in depth, with treatment of different bead cross sections, bead end shapes, and bead materials. International standards and practices are included.Bending is a most common sheet metal forming operation. Many products like automobile components and its body, home appliance, paper clip, metal doors etc. are shaped by bending process. Before discussing about bending process and its types, first you should learn about basic terminologies used in bending.

bj sheet metal

types of sheet metal bending

sheet metal bending standards

sheet metal bending dies

When working with metal studs, choosing the right electrical box is the first step in a secure installation. There are several types of boxes designed to use with metal framing, which we’ll dive into below.

beading process in sheet metal work|types of sheet metal bending