sheet metal cutting process 5. Sheet Metal Cutting. Sheet metal cutting is done to remove the metal in a particular shape out of the larger sheet of metal. The two categories of sheet metal cutting are bevel and spur gear cutting. The former refers to the . Shipping container sheds vs. metal sheds- which one to go for? We provide you with shipping containers and metal sheds comparison to help you decide which type of storage .

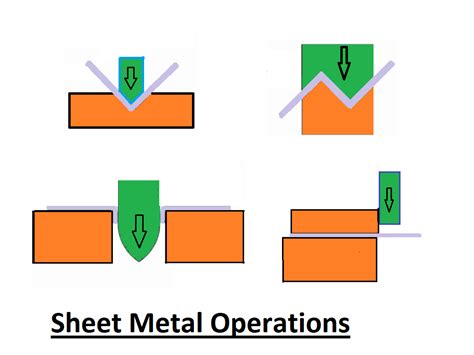

0 · sheet metal operations with diagrams

1 · sheet metal manufacturing process types

2 · sheet metal manufacturing process pdf

3 · perforating operation in sheet metal

4 · notching operation in sheet metal

5 · how to fabricate sheet metal

6 · cutting clearance for sheet metal

7 · blanking operation in sheet metal

$79.99

sheet metal operations with diagrams

The sheet metal cutting process is a particularly important part of fabricating sheets of metal into components of a wide array of consumer and industrial products. Used to remove unneeded material, shearing involves the .Sheet metal cutting operations remove the sheet metal material from larger sheets by applying high forces on the cutting edge. The cutting tool (punch & .

3 piece steel storage cabinet

This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, . It works exceptionally well for sheet metal and thin materials. Water Jet Cutting: Advantages and Applications. Water jets mix water with abrasive particles to cut metal. This cold-cutting process prevents heat distortion. It cuts thick materials while maintaining material properties. Plasma Cutting: A Popular Method for Metal Fabrication . 5. Sheet Metal Cutting. Sheet metal cutting is done to remove the metal in a particular shape out of the larger sheet of metal. The two categories of sheet metal cutting are bevel and spur gear cutting. The former refers to the .

Another sheet metal cutting process is water jet cutting. Water jet cutting is a machining method that uses a high-pressure jet of water (mixed with an abrasive substance) to cut through the metal. Water jet cutters are particularly useful for cutting sheet metals with a low melting point since they do not generate heat which could unduly deform the metal. Sheet metal cutting, a fundamental process in the metalworking industry, involves the precise removal of material from sheet metal stock to form a specific part or component. This process, essential in shaping the metal sheet into a finished part, employs various tools and techniques, ensuring accuracy and efficiency.

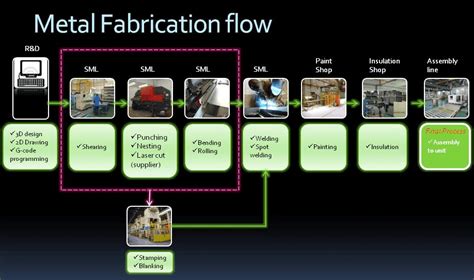

Slitting is an important part of the overall sheet metal cutting process since it is needed to create sheet metal pieces of a specific width for other machines to be able to cut them properly. Since sheet metal mostly arrives in the form of the coil to the factory, it is fairly common for slitting to be used as the first part of the sheet metal . Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability. Process3-CNC Milling cutting. CNC milling cutting is a process typically used to produce complex metal parts. The metal parts produced by milling machines are highly precise. In this process, the computerized programming code operates different machines and tools to cut the soft metals and give them a specific form.

Factors Affecting Metal Cutting. Some of the factors that affect metal cutting are: Cutting speed: The relative speed between the cutting tool and the workpiece. Feed: The rate at which the cutting tool advances into or along the workpiece. Depth of cut: The thickness of the layer of material removed by one pass of the cutting tool. Cutting tool material: This is a . During the stamping process and cutting phase, the metal sheet is placed in a press, where a punch forces it through a die. This action shears the metal deformation along the die’s edges to produce the desired part. The blanking process typically yields clean, smooth edges, although there may be instances of rough edges or burrs that need . Hi Friends,In this video you will learn Different types of Cutting operation in sheet metal | Sheet metal cutting operationsShearingCutoff Parting offBlankin. Sheet metal nibbling process. Nibbling is a sheet metal cutting technique that involves removing material incrementally. Nibbling allows for intricate patterns, curves, and shapes by creating overlapping holes or notches. Instead of cutting through the material in one go, nibbling makes multiple, small, and controlled cuts to achieve the .

It’s the operation of cutting, shaping, punching, and pressing sheet metal to assemble it into finished products. Sheet metal fabrication often starts with metal shearing, which prepares the material for subsequent operations such as bending or welding. It’s a process that cuts sheet metal into specific shapes and sizes. Metal notching is an important technique in metal fabrication process. A reason this guide explores everything about notching process. From benefits, limitations, classification to applications; you will learn everything about notching sheet metals. Keep reading to learn more. What is Sheet Metal Notching? Notching sheet metal involves removing unwanted metal [.]Process that involves cutting sheet metal, plates, bars, and tubing. punching. bending. friction. shearing. 4 of 31. . Process where sheet metal is clamped around its edges and is stretch over a die or form block. Used for large parts such as aircraft-wing skin . Sheet metal cutting for small projects; Shearing. . The exact speed of any metal cutting process depends on the type and dimension of the workpiece. What is the most accurate metal cutting process? Waterjet cutting .

To address the issues of workpiece distortion and excessive material melting caused by heat accumulation during laser cutting of thin-walled sheet metal components, this paper proposes a segmented optimization . Types of Sheet Metal Fabrication Techniques. As mentioned above, there are a variety of techniques used during the sheet metal fabrication process. Let’s take a closer look at each of them. Sheet Metal Cutting Techniques Shearing. Shearing is one of the most basic and widely used sheet metal cutting techniques. Sheet metal cutting for small projects; Shearing. . The exact speed of any metal cutting process depends on the type and dimension of the workpiece. What is the most accurate metal cutting process? Waterjet cutting is the most precise cutting method with a tolerance of +/- 0.001″. Laser cutting can also provide similar accuracy to this value.

The shear cutting process causes the formation of residual stresses in the cut segments from the non-oriented electric sheet metal, resulting in increased iron losses. Laser cutting sheet metal is the thermal process that involves using a laser beam to cut out pieces off a metal sheet. Primarily, there are three methods of cutting sheet metal. Laser Beam Fusion Cutting. Fusion cutting uses an inert cutting gas, often nitrogen or argon, to thrust out the molten material from the cutting torch. Since using the .Forming sheet metal. During the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized product. Entire product chassis can be made in this way. Not only is forming metal convenient, it also adds strength and stiffness to an assembly.The sheet metal laser cutting design process starts in CAD software. The CAD design sets the dimensions and shapes that need to be cut from the metal sheet. #2: Material Set Up. The metal sheet that will be laser-cut is securely placed onto the cutting bed of the laser-cutting machine. Thankfully, the machine's controls tell us whether the .

For the shearing process in sheet metal, sheets are fabricated into multiple components – all of which can now be used to manufacture different items. The metal material itself is cut precisely and accurately, with the objective being the overall removal of any unwanted or unrequired particles. . Here, sheet metal is cut along a straight .TECOI and FANUC team up to produce state-of-the-art CNC sheet metal cutting machine Task: To keep improving machine performance, stay competitive, improve precision, limit machine downtime and shorten the work process to save time and increase productivity. Solution: To equip the sheet metal cutting machines TECOI produces with easy-to-programme FANUC series 31i . The process of computer-aided design and manufacturing of sheet metal parts starts with computer-aided design, goes through numerical simulation unfolding, nesting, cutting, stamping, bending, and other procedures, and ends with the computer automatically outputting the part’s process route, operation content, tooling motion trajectory (tool . It is the process of cutting a complete piece of sheet metal. In which there is ample junk all around, as shown in fig. For this type of sheet metal operation, a punch and die are used. Punching Operations. A punch-and-die technique is used .

sheet metal manufacturing process types

sheet metal manufacturing process pdf

3/32 sheet metal

perforating operation in sheet metal

Only 2 left in stock - order soon. The Wright Foam Box weighs 27LBS which allows for safe storage and moving around your box. The Wright Foam Cube is constructed of 32 shore hardness foam and wrapped in a Heavy Duty Vinyl shell. With indicator marks easily showing the height setting. Wright Equipment. Would you like to tell us about a lower price?

sheet metal cutting process|blanking operation in sheet metal