sheet metal development drawing limited purpose of pattern development, this book meets every requirement of an apprenticeship textbook and is, in addition, also well adapted for . a course in sheet-metal pattern drafting: Drawing board, 24" x 30", T-square, 30"; 45 ° triangle, 10”; 30° x 60° triangle, 10";

Twin Box Spring - 7 Inch High Profile Box Spring for Twin Bed, Sturdy Metal Frame Mattress Foundation, Easy Assembly, Quiet & Noise-Free

0 · simple sheet metal drawings

1 · sheet metal pattern layouts pdf

2 · sheet metal pattern layout methods

3 · sheet metal layout drawings

4 · sheet metal drawing templates

5 · sheet metal development drawing pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

Waterproof IP68 External Junction Box, 2 Way Plug Line M20 Coaxial Cable Connector Wire Range 5 to 15mm Outdoor External Electric Power Cord Boxes (Black-2pcs)

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. .The construction of 3-D models from pieces from flat cardboard or thin sheet metal requires some mathematical and geometrical application. Starting with simple 3-D forms, we can calculate . Introduction. I. Geometric Construction. 1. Construct Triangles - "Triangulation" 2. Bisect a Line. 3. Bisect an Arc. 4. Bisect an Angle. 5. Copy an Angle. 6. Create a Parallel Line. 7. Create a Perpendicular Line. 8. Draw an .Sheet-Metal Pattern Drafting What processes are used to form metal objects made from patterns? Metal that has been formed into very thin, fl at sheets is called sheet metal. It is available in .

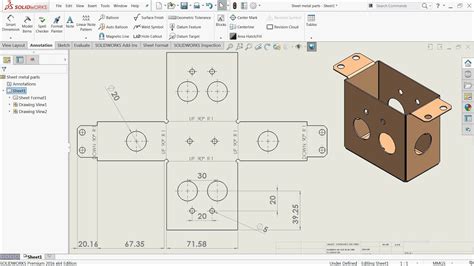

in this tutorial video we will learn how to sketch sheet metal drawings in Solidworks with the help of sheet metal tools.Please subscribe our channel for mor.

limited purpose of pattern development, this book meets every requirement of an apprenticeship textbook and is, in addition, also well adapted for . a course in sheet-metal pattern drafting: Drawing board, 24" x 30", T-square, 30"; 45 ° triangle, 10”; 30° x 60° triangle, 10";Xometry’s Sheet Metal Tolerance Offerings If a drawing or specification sheet has not been provided by the customer, Xometry will manufacture the product from the model to the specifications listed below: Tolerances • Forming and bending: +/- 0.020” • Bend to hole or feature: +/- 0.010”

trick dog metal money box

A line drawing of the Internet Archive headquarters building façade. An illustration of a computer application window Wayback Machine. An illustration of an open book. Texts. An illustration of two cells of a film strip. . sheet metal drawing .

22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.The webpage provides information on developing patterns from sheet materials for engineering purposes.Sheet Metal Drawing & Pattern Development by Alfred Dickason, February 1983, Sportshelf & Soccer Associates edition, Paperback in English

Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control

Get Textbooks on Google Play. Rent and save from the world's largest eBookstore. Read, highlight, and take notes, across web, tablet, and phone.Sheet Metal Development Drawing (411 products available) Most precision laser cutting service sheet metal fabrication customize demand development drawing 0.00 - 0.00. Min Order: 1 metric ton. These range from tools for the design of sheet-metal parts with Solid Edge as educational tools , and assisted manufacturing for drawing sheet-metal parts , to visual inspection techniques with CAD data , manufacturing technologies from CAD files , the application of CAD/CAM technology in the development and lofting of complex sheet parts .Mar 17, 2022 - Explore Pyse Matemane's board "Boiler making drawings" on Pinterest. See more ideas about sheet metal fabrication, sheet metal drawing, metal fabrication. Pinterest. Today. Watch. Shop. Explore. . Development of patterns from sheet materials - Engineering Drawing. Development of patterns from sheet materials - Engineering Drawing.

SolidWorks II Sheet Metal II Total Developed Length (Flat Length) Calculation.In this video, I am going to explain, how to calculate Total Developed length .Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematic

Draw an Arc Through Three Points 25 9. Divide a Circle Into 12 Equal Parts 29 10. Divide a Line Using a Ruler on an Angle 31 11. Create a Hexagon 33 . Pattern Development: Sheet Metal Level 1. and • . • . About BCcampus Open Education . Pattern Development: Sheet Metal Level 1. BCcampus Open Education.Draw a full elevation view and plan view. Draw in all element lines in both views. An element line which appears as a dot in one view, is a true length in the other view. As well, a line parallel to the x-axis in the plan view is also a true length in the elevation view. Label the element lines. This video Tutorial will be very helpful to our Engineering students.In This Video we learn "Development of Sheet Metal Tray".Development of Surface of a Sol.This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles, while very appropriate for others. Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical.

Flat Pattern (FP): It is the planar drawing of the blank required to form the desired sheet metal component. Flat Pattern Development (FPD): It is the process of determining flat pattern for a sheet metal component corresponding to its neutral surface. The neutral surface is the surface within the sheet that is parallel to the inner andTo meet unique sheet metal design challenges, like manufacturability, Solid Edge streamlines the entire sheet metal product development process, from CAD design through flat pattern and drawing development. Unlike general purpose CAD tools, Solid Edge includes sheet metal-specific features, like Emboss, Dimple, Drawn Cut, Bead, Contour Flange . L-shaped metal sheet profile. 25 + 30 + 3,1415/2 x (3 + 0,93) = 61,17 m/m will be the development of the sheet. U shape. Formula: Development = Flat face A + Base + Flat face B + ¶ / 2 x (2 x inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation; U-shaped metal sheet profile

trinity stainless steel cabinet

Study with Quizlet and memorize flashcards containing terms like 8-1. For which of the following reasons should the sheet metal development drawings allow additional material?, 8-2. When drawing a lap seam, the allowance must be how many times the diameter of the rivet being used?, 8-3. If the finished part is not shown with the development, what item should be .

1. Introduction. Hydrodynamic deep drawing (HDD) using liquid (oil or water) as a transmission medium to act on the sheet instead of the rigid die, is a kind of soft-tool forming technology or flexible-forming method [1], [2].Compared with the conventional forming methods, HDD gives many advantages such as saving tooling cost, improving dimensional accuracy, .

Surface development is a full size layout of an object drawn on a plane. Some objects are made of flat sheet metal. When the sheet is cut as per this layout, folded and joined together, it takes the shape of an object. Orthographic projections of the object are drawn first and then the development is drawn. 4. Deep Drawing Techniques. Deep drawing is one of the primary methods used to create complex three-dimensional shapes from sheet metal. The process involves pulling the metal into a die using a punch, forming it into a desired shape. Material stretchability: Ensure the metal can stretch adequately to conform to deep-drawn shapes. Materials .A sheet metal pattern is a(n) _____ drawing of the object. . _____ and _____ are examples of the radial-line pattern development. Used to connect two differently shaped openings. What purpose does a transition piece serve? additional strength and rigidity. The wired edge is added to the edge of a sheet metal object for _____. .

triangle electric box key

Thin sheet metal ( eg, from aluminium drink cans, or heavy aluminium foil baking trays ) Step 1: PRISM. Take the case of a triangular right angled prism as shown in the diagram. Its development is simply a combination of its 5 faces, connected to produce the prism when folded along the edges. . Although the author mainly describes engineering .

simple sheet metal drawings

Remove old outlet from old box, then use wire nuts to tie the wires in that now-empty box (A) to NEW wire going to a new box (B) Leave the old box (A) as a junction box - just wires tied together -- and cover with an ordinary .

sheet metal development drawing|simple sheet metal drawings